Cooling fan

A heat dissipation fan and fan wheel technology, applied to parts of pumping devices for elastic fluids, non-variable pumps, pump devices, etc., can solve problems such as inconvenience and lack of suitable structures for general products, and avoid blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the cooling fan proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. The description is as follows.

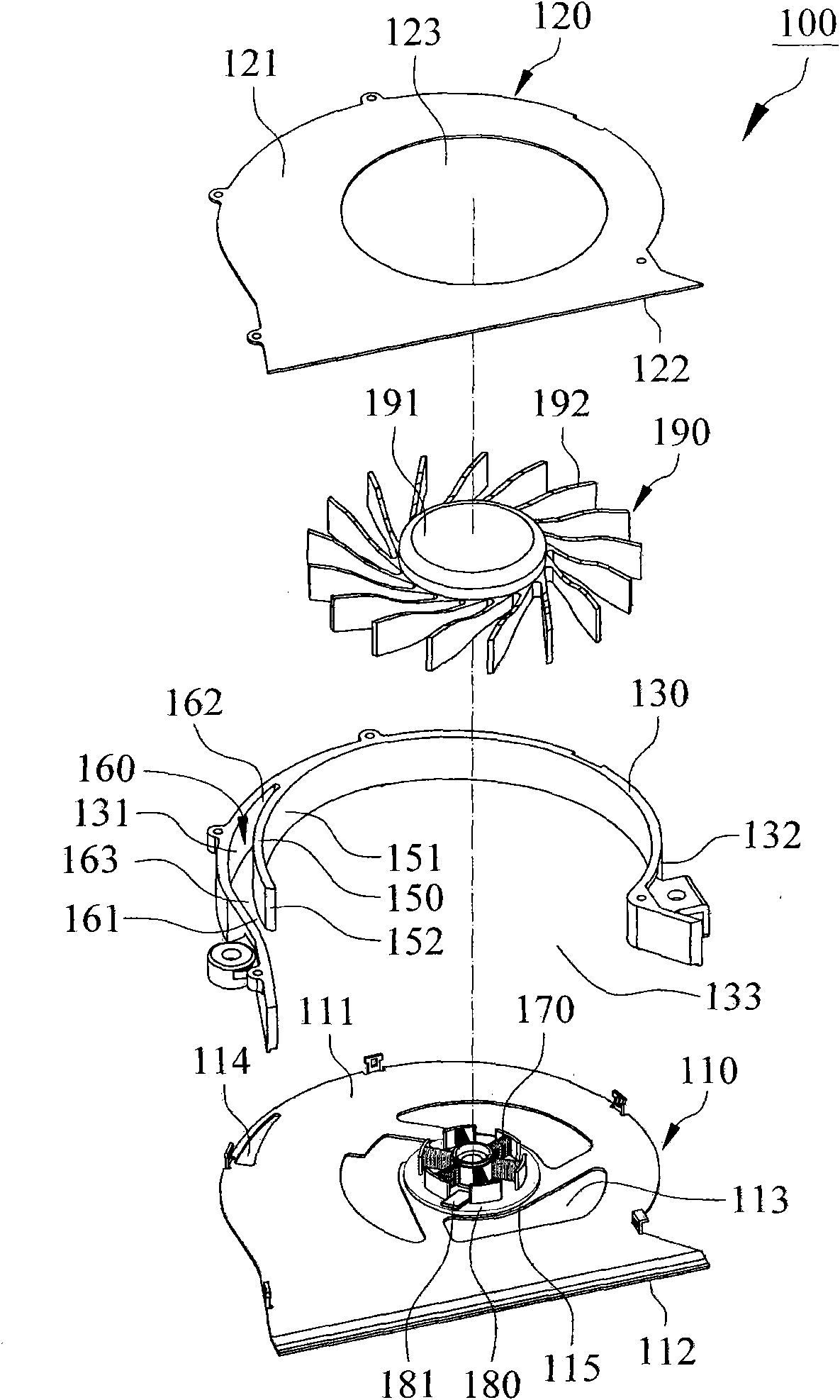

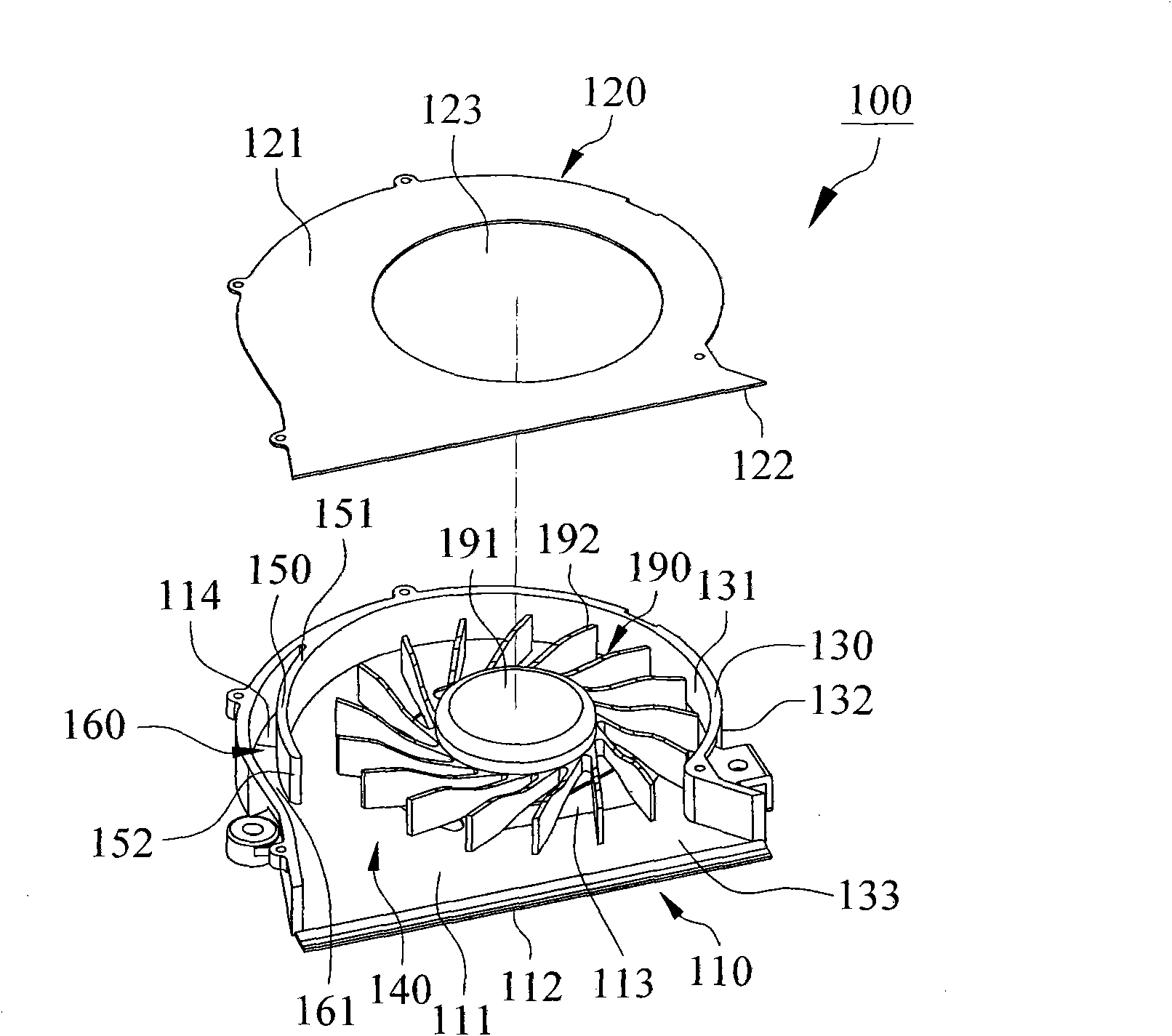

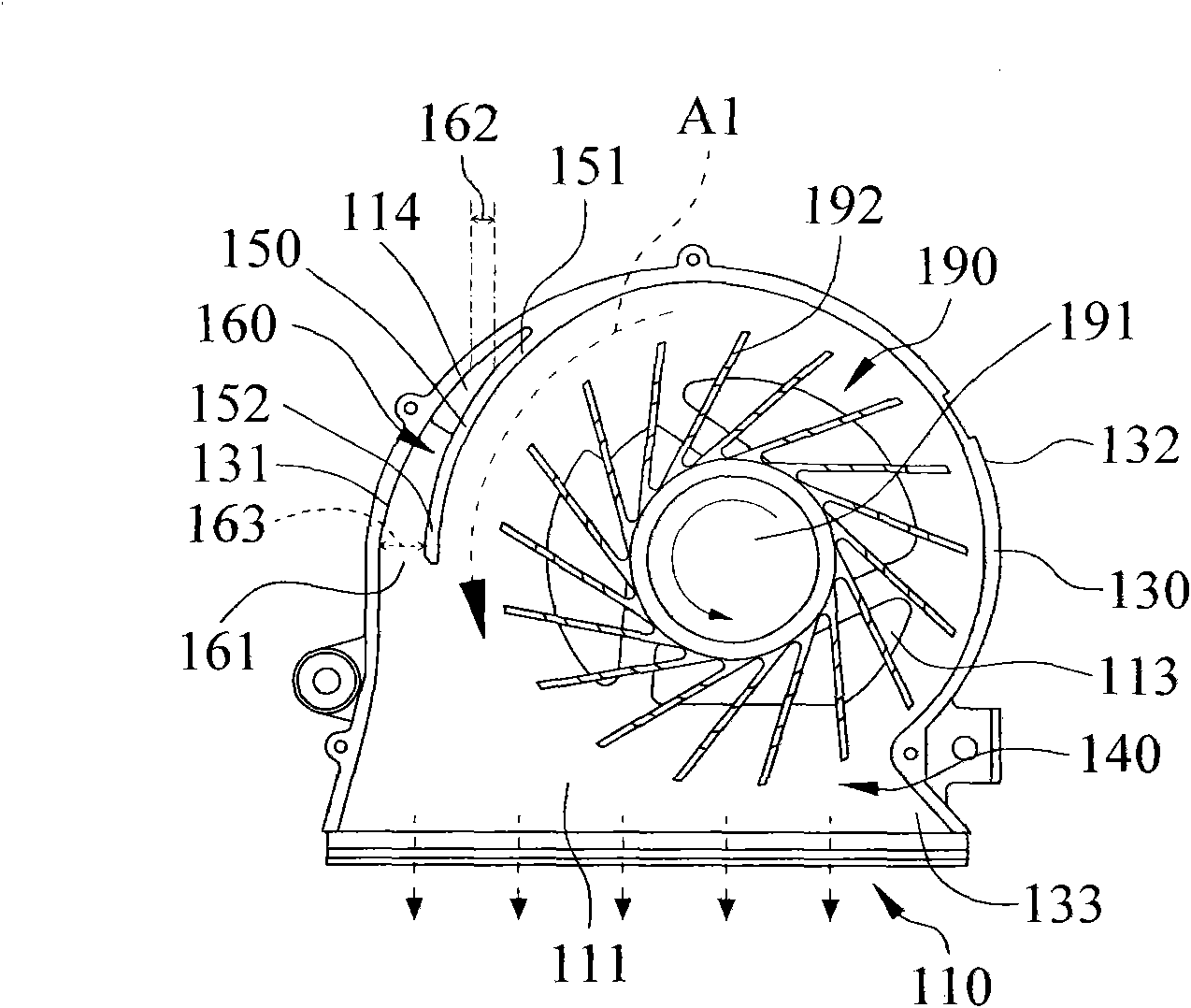

[0097] see Figure 1 to Figure 4 , which is the first embodiment of the present invention, a cooling fan 100 which includes a first board 110, a second board 120, a ring wall 130, a spacer rib 150, a stator 170, a circuit board 180 And a fan wheel 190, the first plate body 110 has a first upper surface 111, a first lower surface 112, a first opening 113 passing through the first upper surface 111 and the first lower surface 112, and A dust outlet 114 that runs through the first upper surface 111 and the first lower surface 112, please refer to figure 1 , in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com