Stone shallow hole blasting control method applied in town

A technology for controlling blasting and stonework, applied in the field of blasting, can solve problems such as high cost, hidden safety hazards of surrounding buildings, and unsatisfactory construction speed, etc., and achieve the effects of low cost, ensuring construction safety, and weakening shock waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

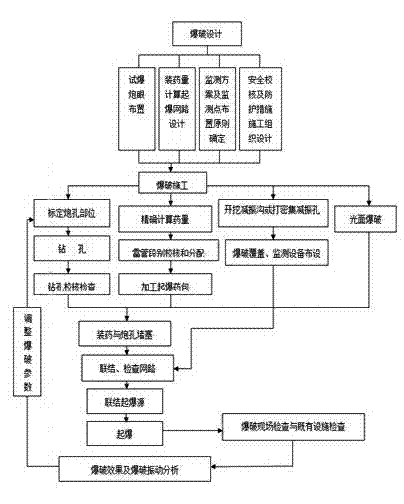

[0019] like figure 1 As shown, the method for controlled blasting of shallow holes in stonework in cities and towns in this embodiment includes a blasting construction preparation stage and a blasting construction specific operation stage.

[0020] Among them, the preparatory stage of blasting construction includes the layout of test blast hole, the calculation of charge amount and the design of detonation network, the determination of monitoring scheme and monitoring point layout, safety check and the design of protective measures construction.

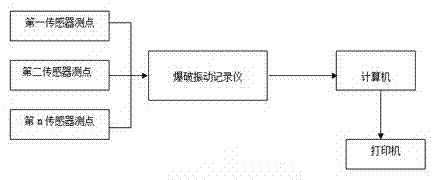

[0021] In the specific operation stage of blasting construction, it includes the calibration of the blast hole position, drilling and drilling check; calculation of charge, detonator section check and distribution, processing of priming charge; at the same time, in order to reduce the vibration caused by blasting , it is necessary to excavate shock-absorbing ditches, carry out blasting coverage and layout of monitoring equipment; if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com