Method for detecting suspension shock absorption performance of automobile power assembly

A technology for automobile powertrain and shock absorption performance, which is applied in the direction of vehicle suspension/shock absorption mechanism testing, etc. It can solve the problems of damage data measurement and inaccuracy of actuating shafts and sensor equipment, so as to ensure accuracy and objectivity and accuracy, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make it easy to understand the technical means, creative features, work flow, and use methods of the present invention to achieve the purpose and effect, the present invention will be further elaborated below.

[0022] The invention discloses a detection method for the damping performance of a suspension of an automobile powertrain, which is realized by means of a vibration test bench capable of realizing two-axis linkage and a two-axis linkage test tool.

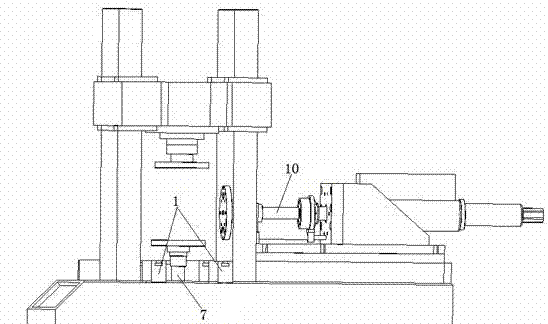

[0023] The vibration test bench that can realize two-axis linkage is standard equipment, and its structure diagram is shown in figure 1 .

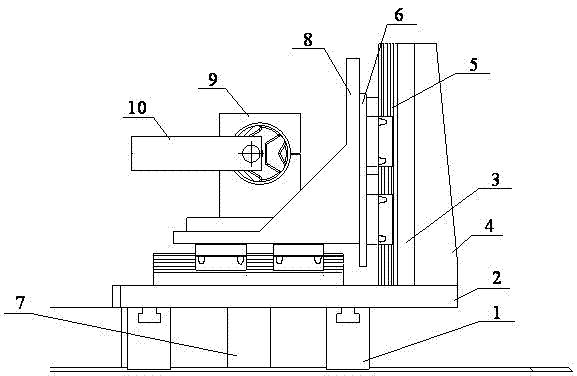

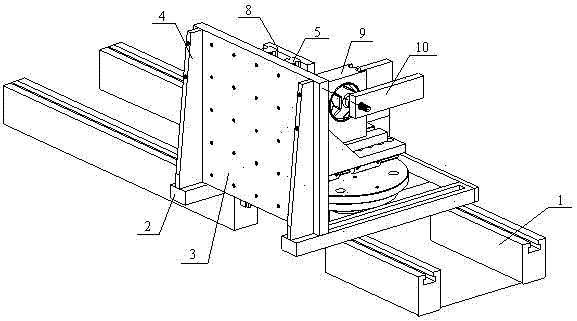

[0024] Such as figure 2 , image 3 As shown, a two-axis linkage suspension test tool includes a frame 1, and a base 2 that can slide on the frame 1 is provided on the top of the frame 1 through bolts. The lower part of the base 2 is hollow so that the vibration actuating shaft and the sensor on the frame 1 have enough space for movement, so that the actuating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com