Material pressing mechanism with material pressing plate capable of being overturned automatically

A technology of automatic flipping and pressing plate, applied in the field of pressing mechanism, can solve the problems of affecting feeding and picking, existing safety hazards, affecting production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

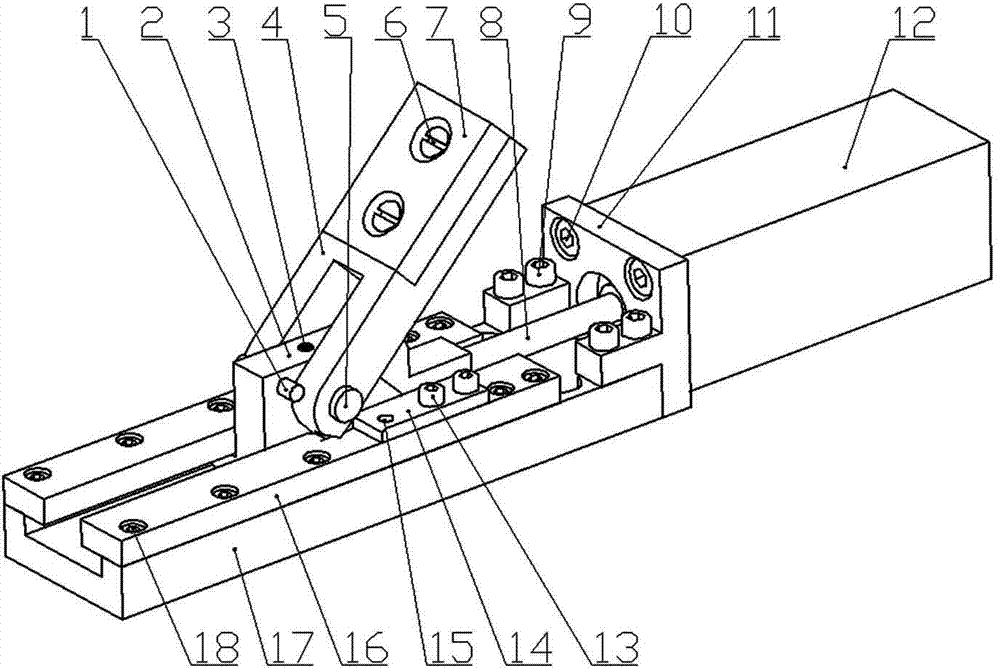

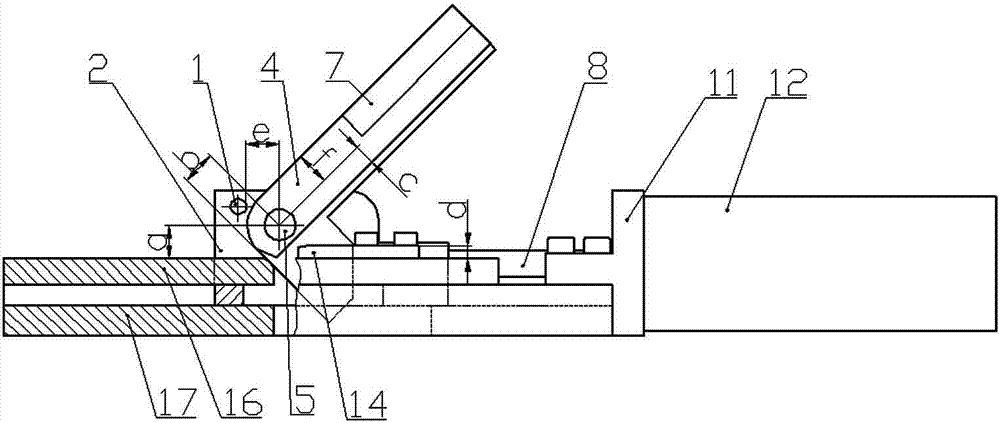

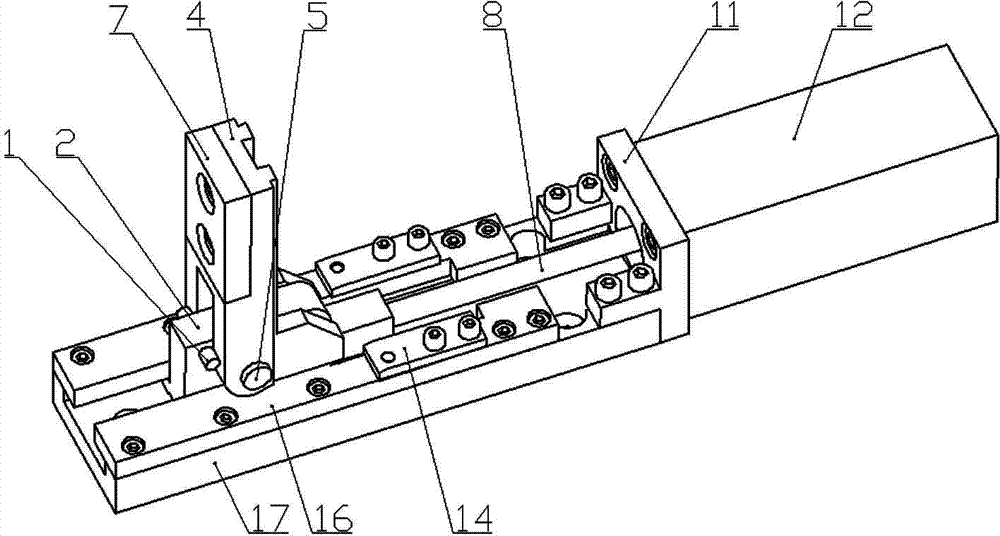

[0018] figure 1 It is an embodiment disclosed by the present invention. The guide rail 17 of the pressing mechanism of the automatic flipping of the pressing plate is fixed on the platform of the stretch bending tool, the cylinder 12 is fixed on the cylinder fixing seat 11 by the screw III10, and the cylinder fixing seat is fixed by the screw II9. 11 is fixed on one end of guide rail 17. The T-shaped slider 2 is inserted between the guide rail 17 and the guide rail pressure plate 16, the T-shaped slider 2 is connected with the piston rod of the cylinder 12 through the connecting rod 8, and can move along the guide rail 17 (see figure 1 and Figure 6 ). The middle part of the short arm end of the L-shaped arm plate 4 is slotted, inserted on the T-shaped slider 2, and the pin shaft 5 connects the corner of the L-shaped arm plate 4 with the T-shaped slider 2, and the L-shaped arm plate 4 Can rotate around pin 5. The long arm end of the L-shaped swivel arm plate 4 installs the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com