Electroplating clamp quick in switching

An electroplating fixture and fast technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of tediousness, waste of manpower, material resources and energy, and achieve the effect of not polluting the environment and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

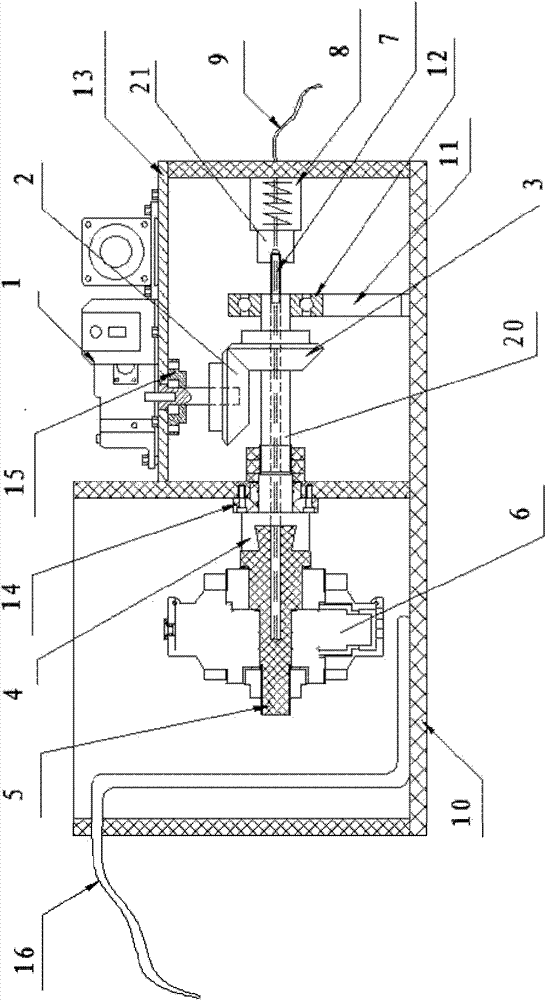

[0009] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention comprises box body 10, and described box body is made up of two parts, and a part is electroplating tank, and another part is mechanical drive box; Motor 1 is set on the upper end cover 13 of described mechanical drive box, and described motor drives the first A bevel gear 2, the first bevel gear 2 meshes with the second bevel gear 3, the second bevel gear 3 is coaxial with the rotating shaft 20, and the rotating shaft is arranged on the bracket 11 through the bearing 12; the rotating shaft 20 is sealed The part of the device 14 protruding into the electroplating tank is provided with a card slot 4, which cooperates with the wedge-shaped end of the quick-change lever 5, and the electroplating part 6 is arranged on the quick-change lever 5; the hollow part of the rotating shaft 20 is provided with a conductive A rod 7, springs are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com