Large-wing bridge section

A section and bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as bridge deck width and landscape restrictions, and achieve excellent overall stability, wide bridge width, and full dynamic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

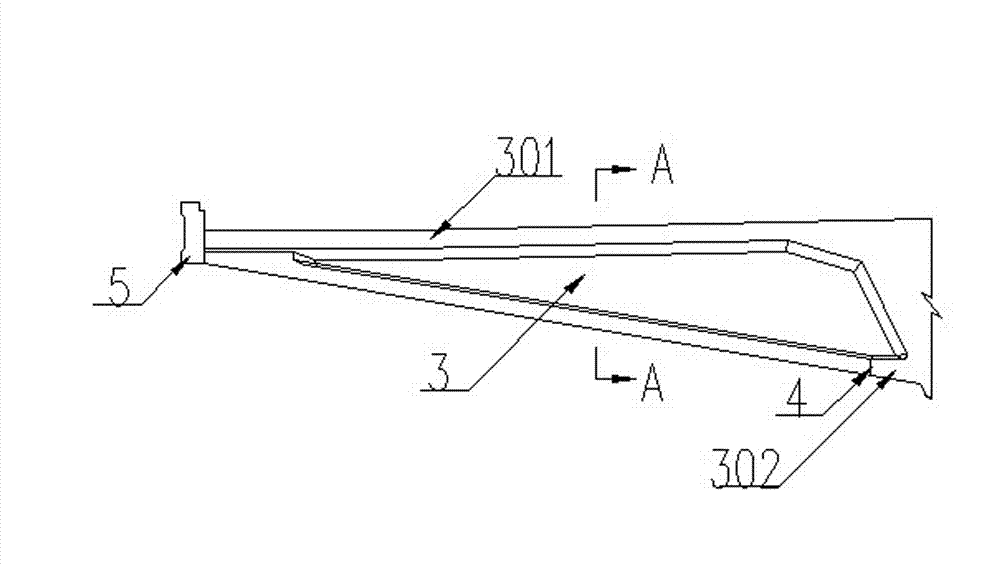

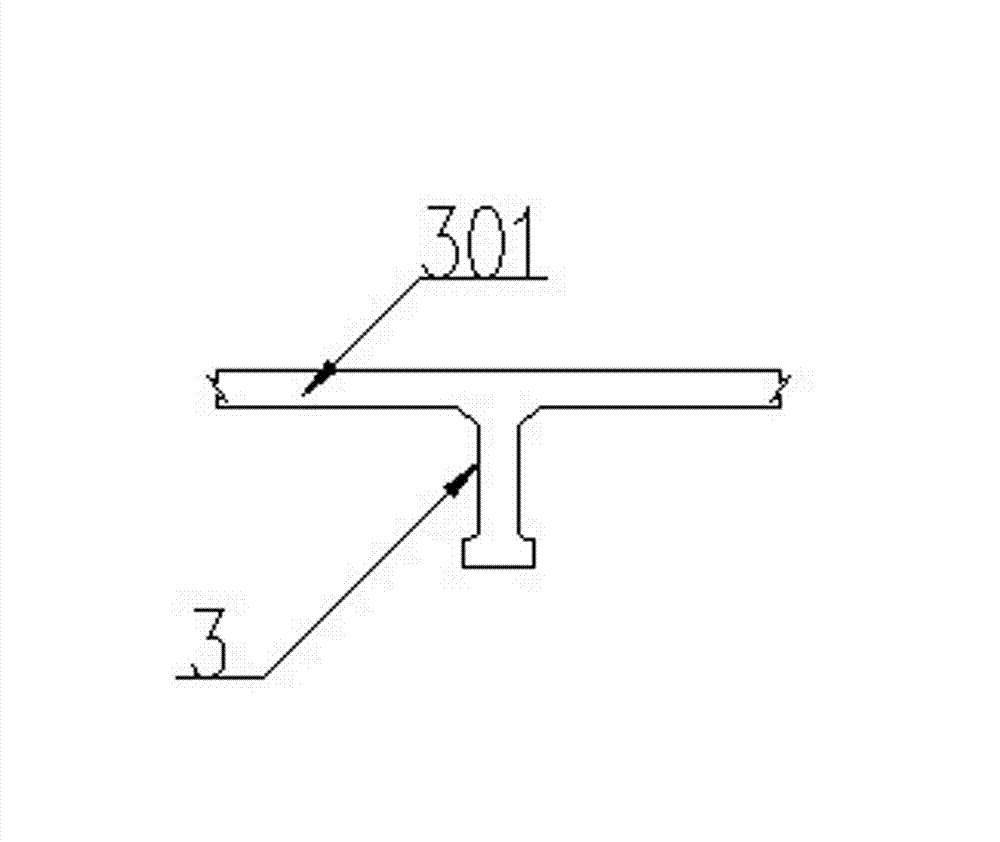

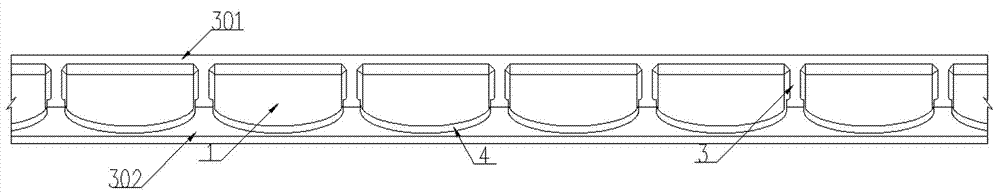

[0028] Example 1 Figure 1 to Figure 3 Shown: A large wing-type bridge section, including box girder, is characterized in that: a single box is provided in the middle of the box girder section, and the single box is horizontally provided with two chambers. This embodiment is suitable for bridges with moderate widths. In the room along the box girder 1, there is an inner partition 2 in the longitudinal direction of the box girder 1. figure 2 Shown as 2×4, that is, eight box chambers 101, the two sides of the single box body are provided with large spread-wing T-shaped cantilever beams 3.

[0029] See figure 1 versus image 3 : The end of the large winged T-shaped cantilever beam 3 is provided with a post-cast small longitudinal beam 5 along the longitudinal direction of the bridge body to ensure the structural integrity and strengthen the stability of the bridge.

[0030] See Figure 4 versus Figure 5 : The large winged T-shaped cantilever beams 3 on both sides of the single box b...

Embodiment 2

[0033] Example 2 see Image 6 : This embodiment is suitable for bridges with a narrow width. A single box is provided in the middle of the box girder section, and the single box is provided with a chamber transversely; the rest is similar to the first embodiment.

[0034] Example 2 see Figure 7 : This embodiment is suitable for bridges with a wider width. A single box is provided in the middle of the box girder section, and the single box is horizontally provided with four chambers. The rest is similar to Example 1.

[0035] In the specific design, according to the width of the bridge, choose to design a single box room or multiple box rooms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com