Split design method for thickness of automobile leaf spring

A technology of leaf spring and automobile steel plate, applied in the direction of low internal friction spring, spring/shock absorber, leaf spring, etc., can solve the problems that cannot meet the design requirements, and achieve the effect of simple and reliable analytical design method and accurate design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

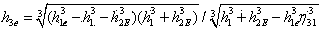

[0018] Embodiment one : The required value of leaf spring stiffness for a truck suspension ,width b = 40mm, total length L =1400mm, elastic modulus of leaf spring material .

[0019] The split design method of the automobile leaf spring thickness that the embodiment of the present invention provides, concrete steps are as follows:

[0020] (1) Calculation of Equivalent Thickness of Leaf Spring in Single-piece Design

[0021] According to the stiffness value required by the automobile suspension for the leaf spring , total length of leaf spring L = 1400mm and leaf spring width b =40mm, determine the equivalent thickness of the single-piece design leaf spring =23.4mm;

[0022] (2) Determination of the length of each leaf spring and design of its thickness

[0023] 1) Determine the length and design thickness of the first leaf spring h 1 : Half length of the first leaf spring is l 1 = L / 2=700mm, according to equivalent thickness h 1e Select Design Thickne...

Embodiment 2

[0035] Embodiment two: Stiffness requirements of a small truck suspension leaf spring ,width b = 40mm, total length L =1200mm, elastic modulus of leaf spring material .

[0036] Using the design steps in Example 1, the split design results can be obtained. The length and thickness of the first piece to the fourth piece are as follows:

[0037] L 1 =2× l 1 =1200mm, h 1 =10mm;

[0038] L 2 =2× l 2 =1120mm, h 2 =10mm;

[0039] L 3 =2× l 3 =1040mm, h 3 =10mm;

[0040] L 4 =2× l 4 =960mm, h 4 =10mm.

[0041] A vertical load of 375N is applied to both ends of the four leaf springs obtained by splitting, and the vertical deformation is 10.01mm, that is, the design stiffness of the leaf spring is 74925.1N / m, and the relative error with the required value of the leaf spring stiffness is only 0.10 %, the experimental results show that the four leaf springs obtained by the split design can meet the stiffness requirements of the suspension leaf springs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com