Electronic device shell and manufacturing method thereof

The technology of an electronic device and manufacturing method is applied in the directions of antenna support/installation device, electrical equipment casing/cabinet/drawer, circuit, etc., and can solve problems such as affecting the service life of electronic devices, easy degumming of antenna, and affecting antenna receiving effect, etc. To achieve the effect of long service life, good signal reception and not easy to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

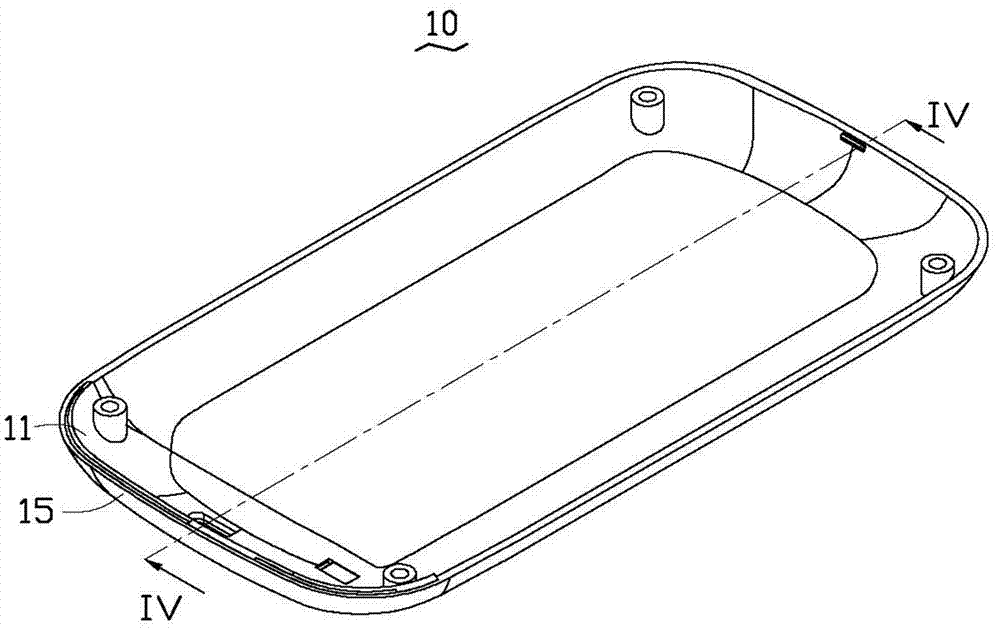

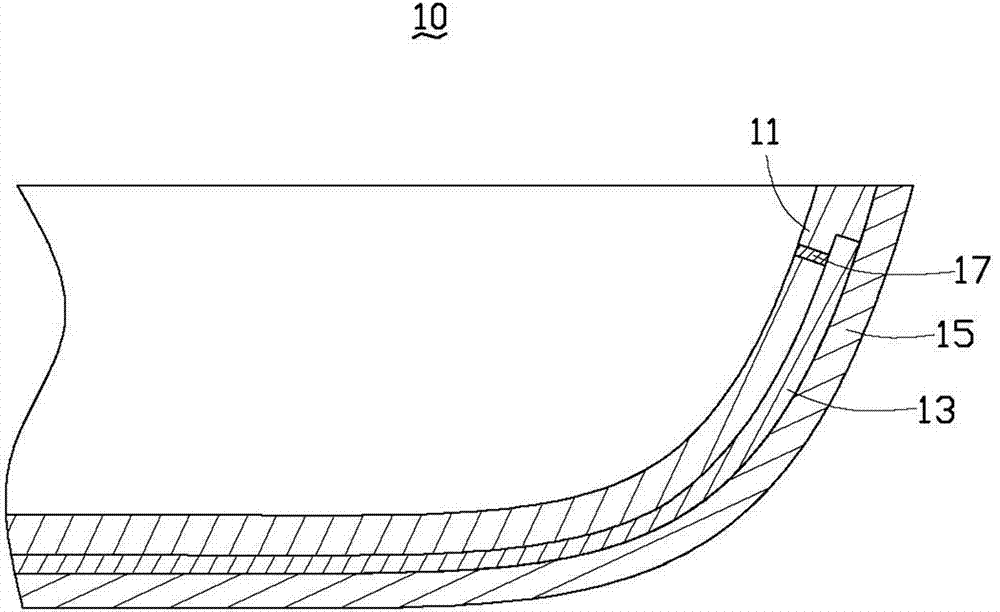

[0018] see figure 1 with figure 2 , The housing 10 of the electronic device according to the preferred embodiment of the present invention includes a base layer 11 , an antenna layer 13 , and a decoration layer 15 . The base layer 11 is formed by injecting plastic through injection molding, the antenna layer 13 is formed on the outer surface of the base layer 11 by injecting conductive plastic, and the decoration layer 15 is formed on the antenna layer by magnetron sputtering or non-conductive vacuum plating 13, and completely cover the antenna layer 13, of course, the decorative layer 15 can also partially cover the antenna layer 13.

[0019] The electronic device casing 10 further includes a conductive element 17 , the conductive element 17 is embedded on the base layer 11 and electrically connected to the antenna layer 13 .

[0020] The base layer 11 of the electronic device casing 10 is made by injection molding, and the conductive element 17 is embedded therein. Plast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com