Method for connecting bristle supports having bristles to cover parts during brush production

A technology of cover parts and bristles, applied in the direction of bristle brackets, brushes, applications, etc., to achieve the effect of safe interconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following embodiments of the method relate to the production of toothbrushes. However, the same principles can also be applied to make other types of brushes.

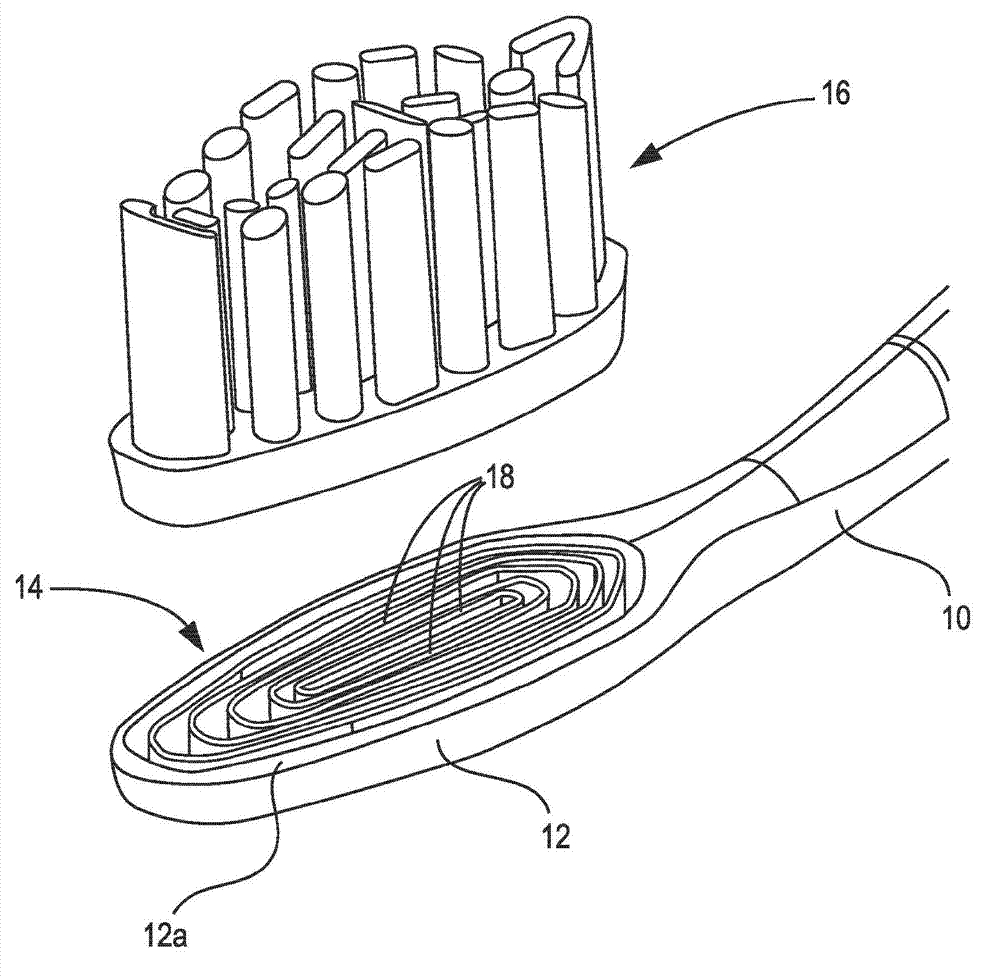

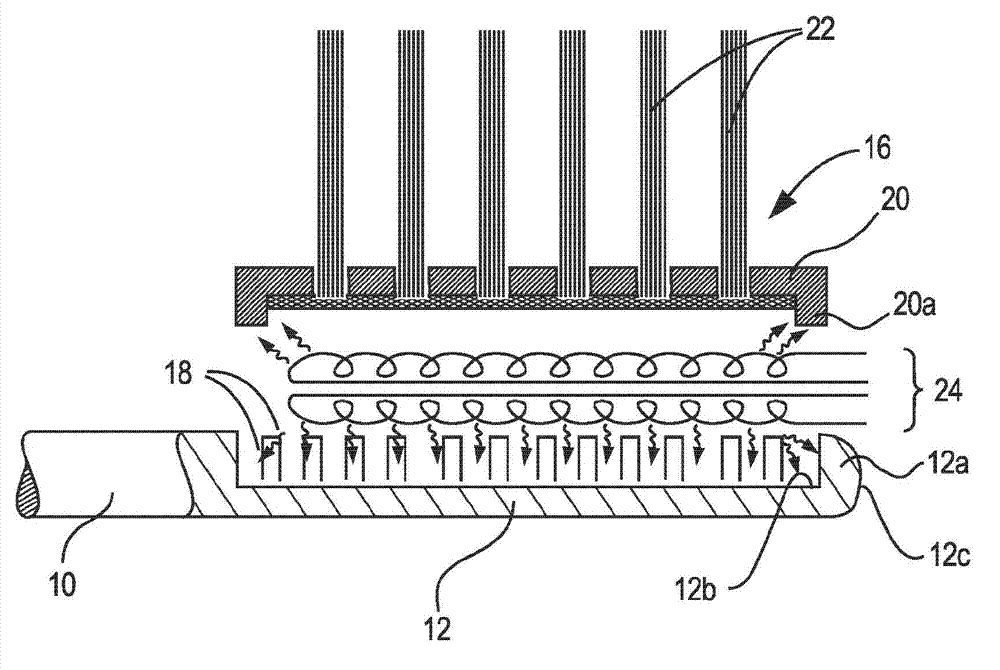

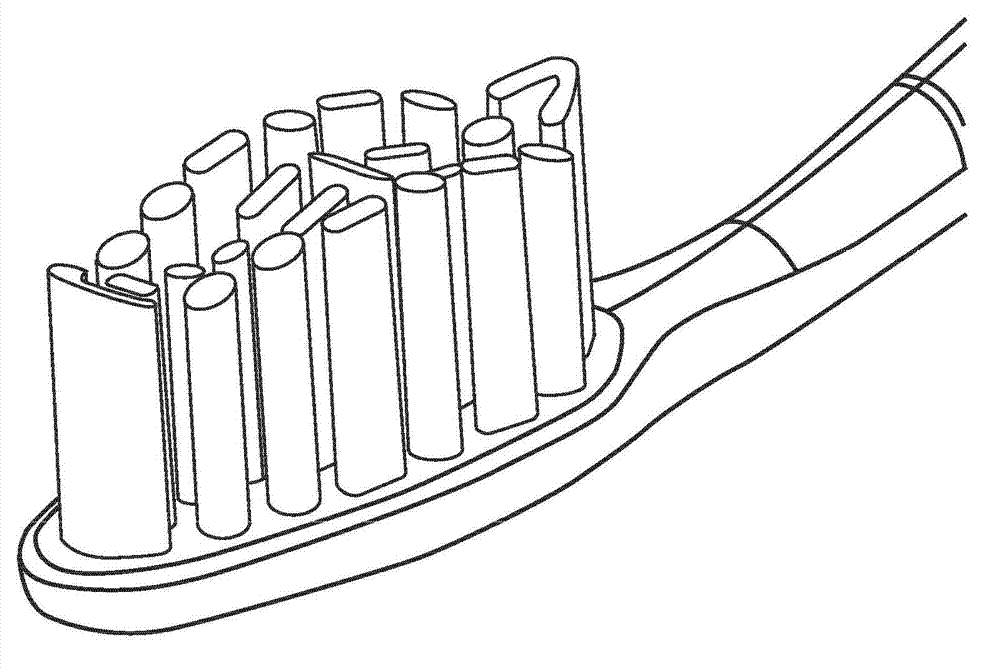

[0040] exist figure 1 3 shows a brush neck 10 in a toothbrush handle and a head part 12 which has a mounting area 14 for a bristle holder in the form of a bristle holder platelet 16 already fitted with bristles. The bristle holder platelets 16 are equipped with variously formed and shaped bristle bundles, which are preferably fixed by the AFT method mentioned at the outset. However, depending on the type of bristles or brush elements, other fastening methods are also possible, such as spraying elastics or gluing natural fibers.

[0041] The fitting area 14 of the head part 12 , also called the cover part, is fitted with a consumption structure in the form of thin ribs having a ring surrounded by each other, said ribs protruding from the bottom of the fixing area. Said rib is surrounded by the outer circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com