Anti-toppling lunch box hand barrow

An anti-dumping and lunch box technology, applied in travel or camping equipment, home appliances, applications, etc., can solve the problems of lunch box tipping, tipping lunch box, side frame easy to dump, etc., to achieve anti-dumping of lunch box, easy opening and closing, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

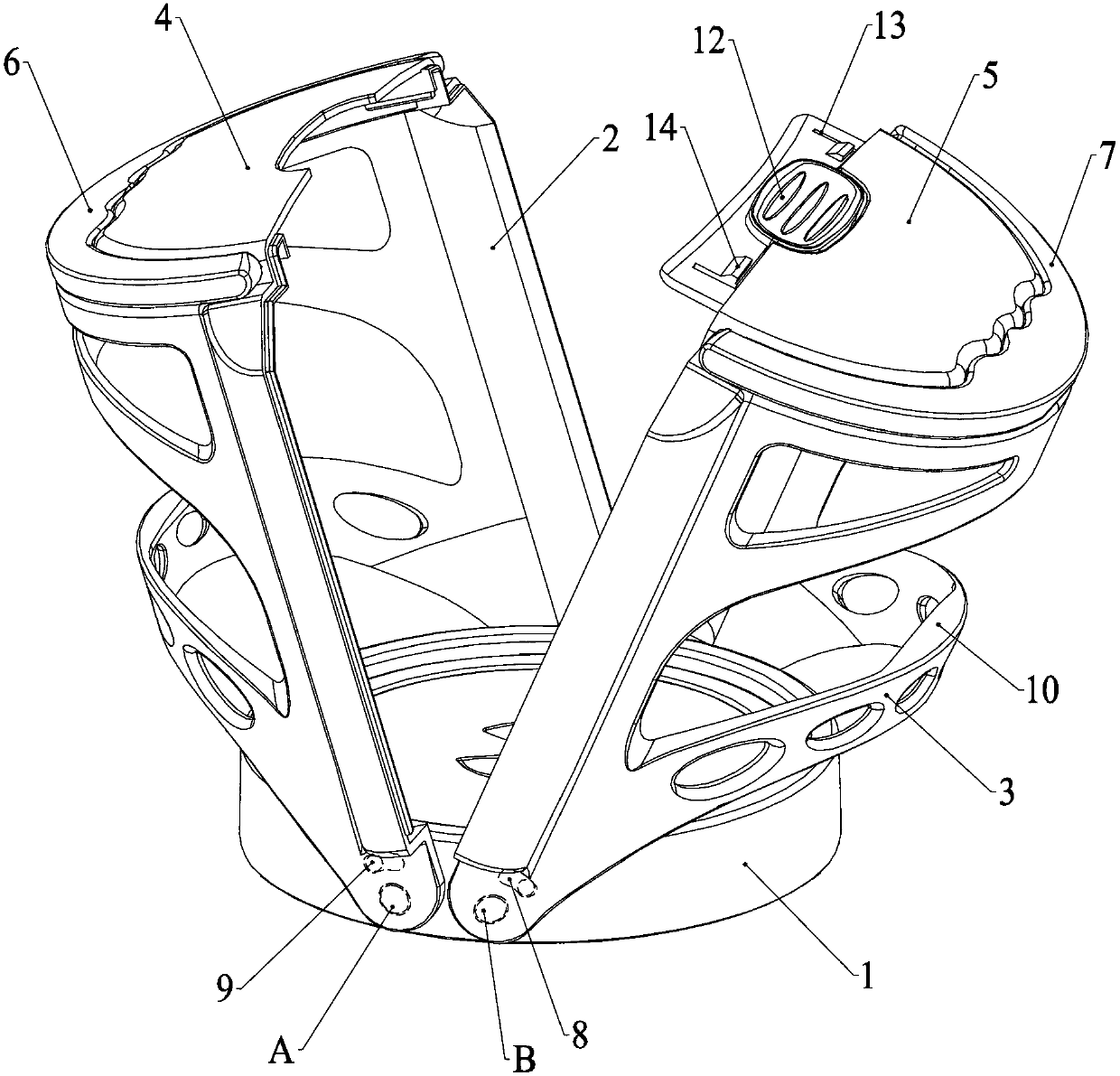

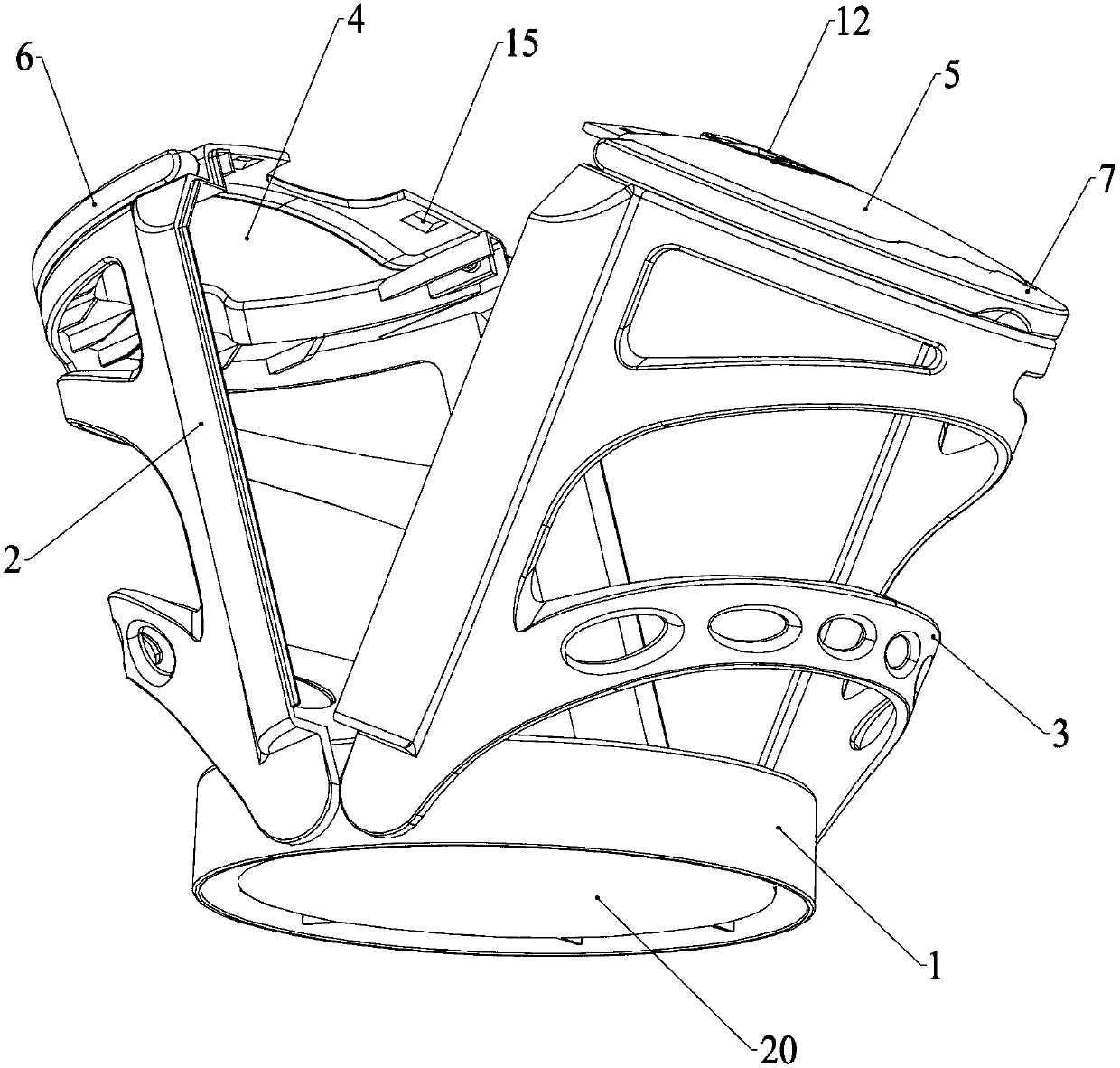

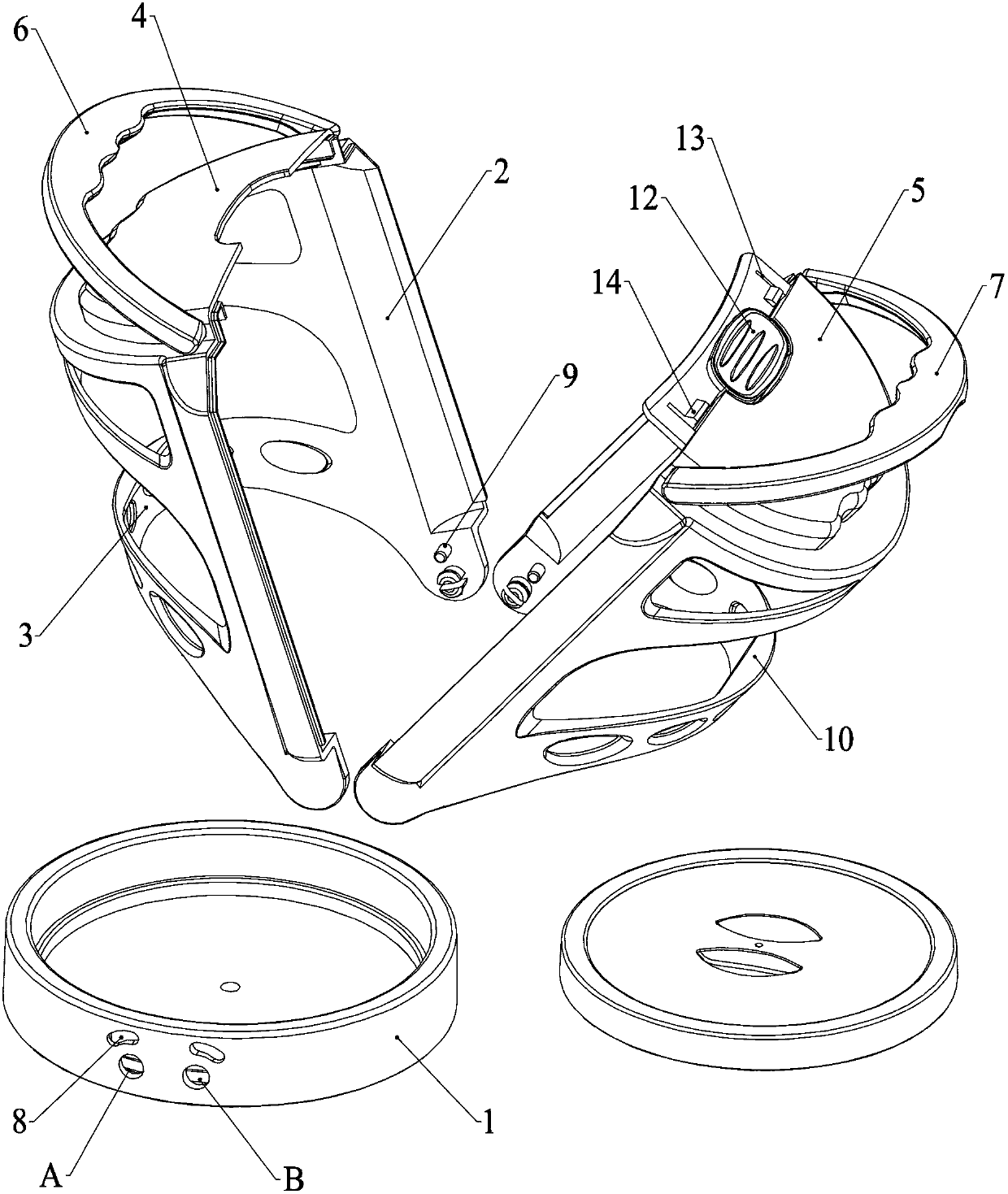

[0027] refer to Figure 1 to Figure 8 , the present embodiment 1 is a two-layer lunch box anti-dumping lunch box rack, including a base 1, a left side frame, a right side frame, a left handle 6, and a right handle 7; The left side frame and the right side frame are composed of the lower ends of the left side frame and the right side frame respectively hinged with the front and rear sides of the base and can rotate around the hinge points A and B of the base; Frame comprises pole 2, lunch box guardrail 3 and top cover 4,5, and left handle, right handle are respectively hinged with the top cover of left side surrounding frame, right side surrounding frame; The junction of the base is also provided with a chute 8 and a slide bar 9 that deviate from the hinge point. The chute is an arc segment set on the base with the center around the hinge point, and the slide bar is arranged on the left side frame and the right side frame. On the top, through the limit of the chute, the flip a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com