Ejecting circulating device and technical method for alkali soaking tank of bottle washing machine

A technology of circulation device and process method, which is applied in the direction of cleaning methods and utensils, chemical instruments and methods, and cleaning hollow objects, etc., which can solve the problems of affecting the washing quality and failing to meet the washing process requirements, so as to improve the washing quality and ensure the washing quality. Quality, the effect of improving the washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

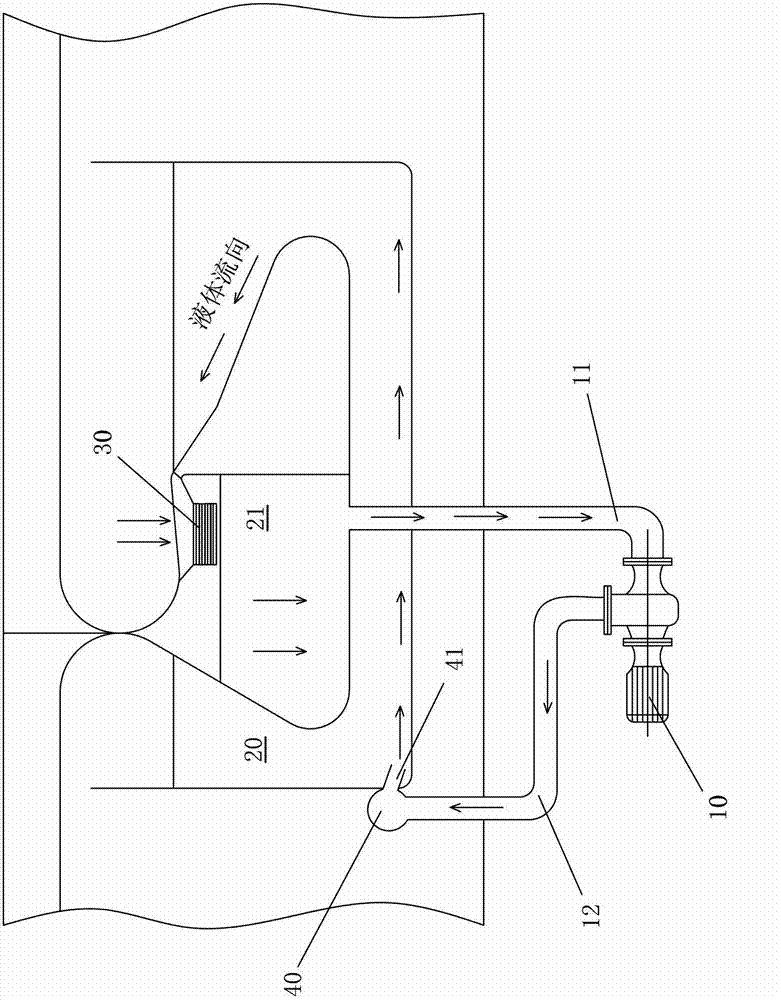

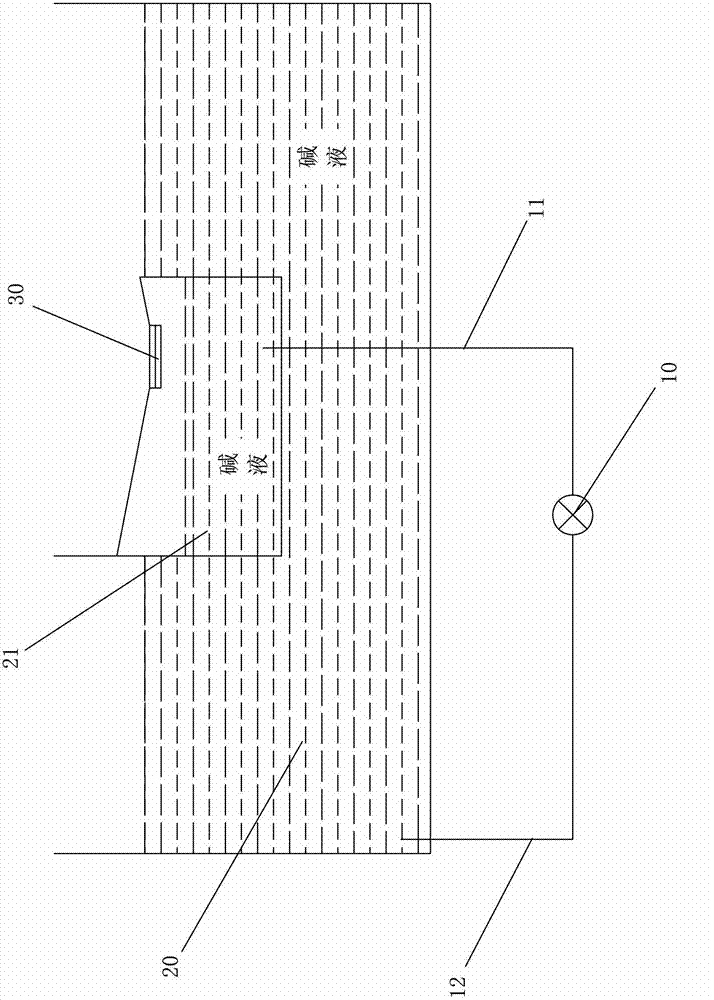

[0025] see figure 1 Shown, the present invention is used for the lye spray flushing circulation device of bottle washer soaking soda pond, comprises a circulation pump 10, and this circulation pump 10 passes through a circulation pump inlet pipeline 11 and circulation pump outlet pipeline 12 respectively, and bottle washing machine The outer alkaline pool 20 and the inner alkaline pool 21 are connected to form a circulation system.

[0026] The circulation pump 10 extracts the lye from the inner alkali pool 21, and transports the lye in the inner alkali pool 21 to the bottom of the outer alkali pool 20 through the circulation pump inlet pipeline 11 and the circulation pump outlet pipeline 12. The specific position is a container bottle Into the bottom of this alkaline pool 20 places. The inner alkaline pool 21 is connected with the spray flushing pipeline 40 installed at the bottom of the outer alkaline pool 20 .

[0027] The lye in the inner alkali pool 21 is sprayed out fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com