Direct-pushing automatic bottom rubbing machine for disc-type porcelain

A bottom grinding machine and porcelain technology, which is applied in the direction of grinding machines, abrasive belt grinding machines, grinding/polishing equipment, etc., can solve the problems of high cost, high labor intensity, and easy grinding of hands, so as to improve the working environment and improve the grinding accuracy , Grinding time adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

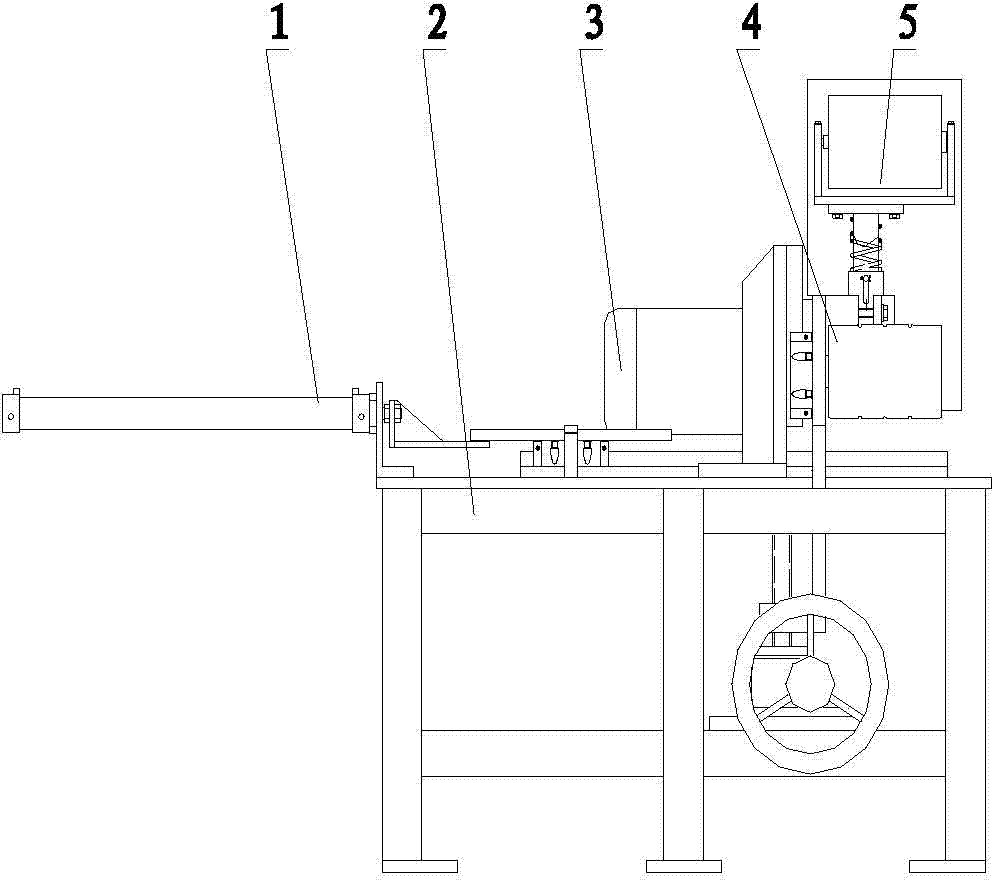

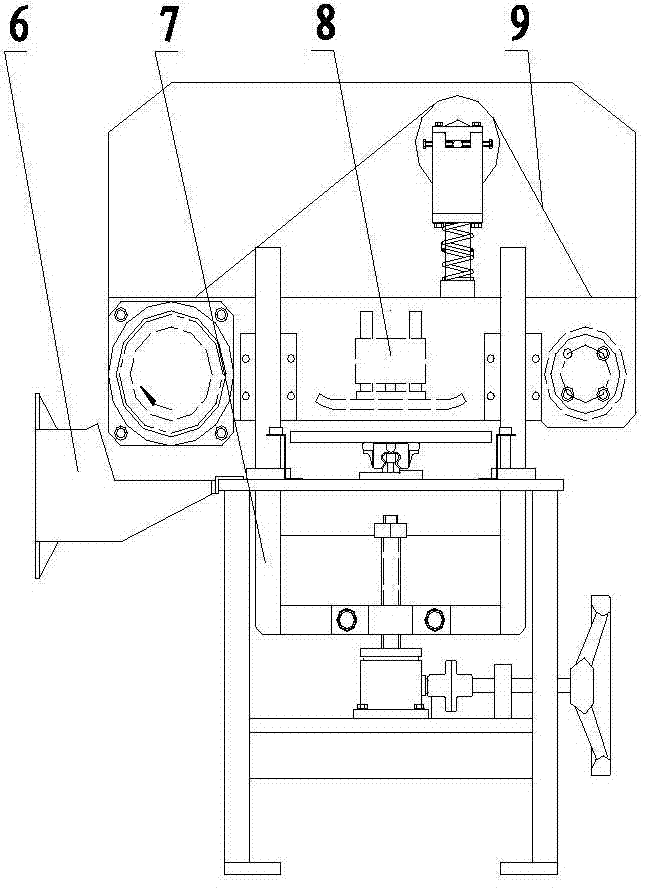

[0027] See Fig. 1 (a) and Fig. 1 (b), direct-push type disc type porcelain automatic bottom grinding machine of the present invention comprises: porcelain entry and exit device 1, frame assembly 2, driving device 3, driven device 4, tensioning device 5. Dust exhaust device 6, lifting device 7, belt pressing device 8, abrasive belt 9 and controller.

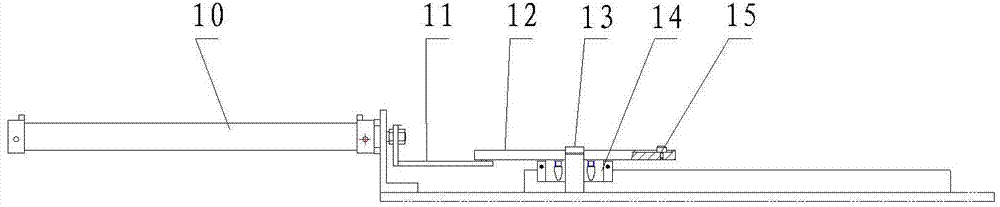

[0028] Porcelain access device ( figure 2 ) is made up of feeding cylinder 10, connecting body 11, porcelain tray 12, through-beam sensor 13, tray guide rail 14, and positioning pin 15. The structural dimension of porcelain tray 12 is related to the length and width of porcelain. The base of the porcelain tray 12 is installed on the tray guide rail 14, and the reason for the use of the beam sensor 12 is: the porcelain is placed on the porcelain tray 12, and the presence of the porcelain is sensed by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com