Structure for preventing stone from being clamped in tire slot

A technology for preventing stone trapping and tires, applied in the direction of tire tread/tread pattern, tire parts, transportation and packaging, etc. Excellent drainage performance, reducing fluid turbulence, improving tire life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

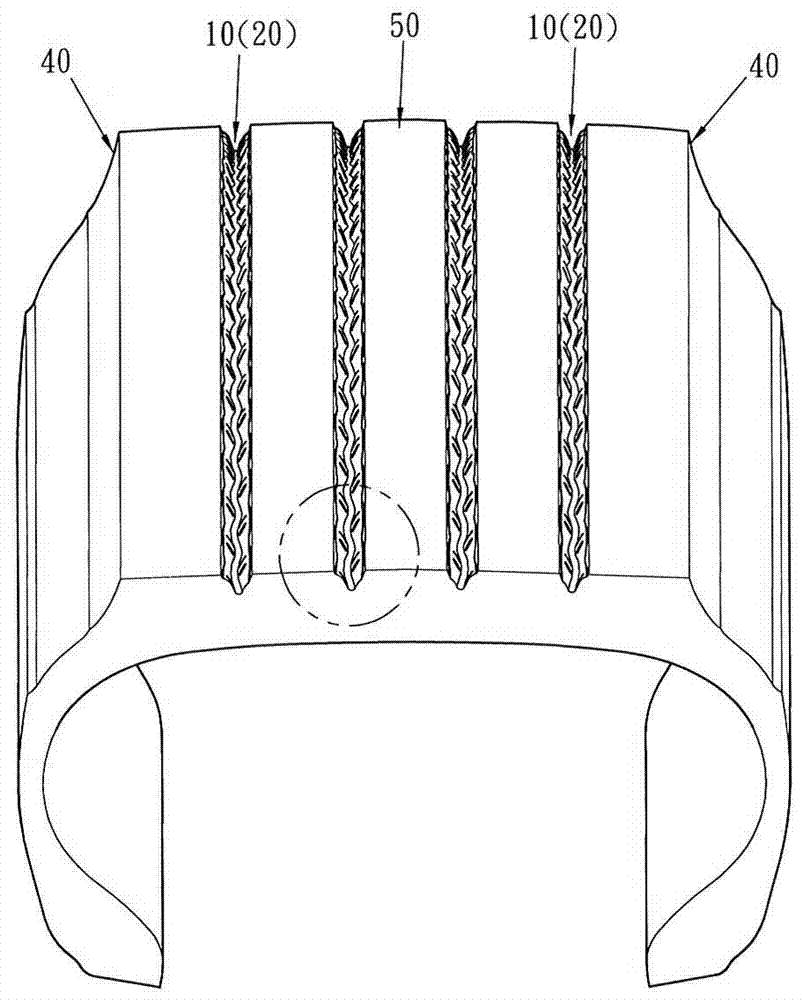

[0034] First please refer to Figure 1 to Figure 4 , the anti-stone structure of a tire groove provided by the present invention is set on a tread 50 in a default quantity, which includes: a tire groove 10, and a tire groove in the groove 10 Convex step group 20.

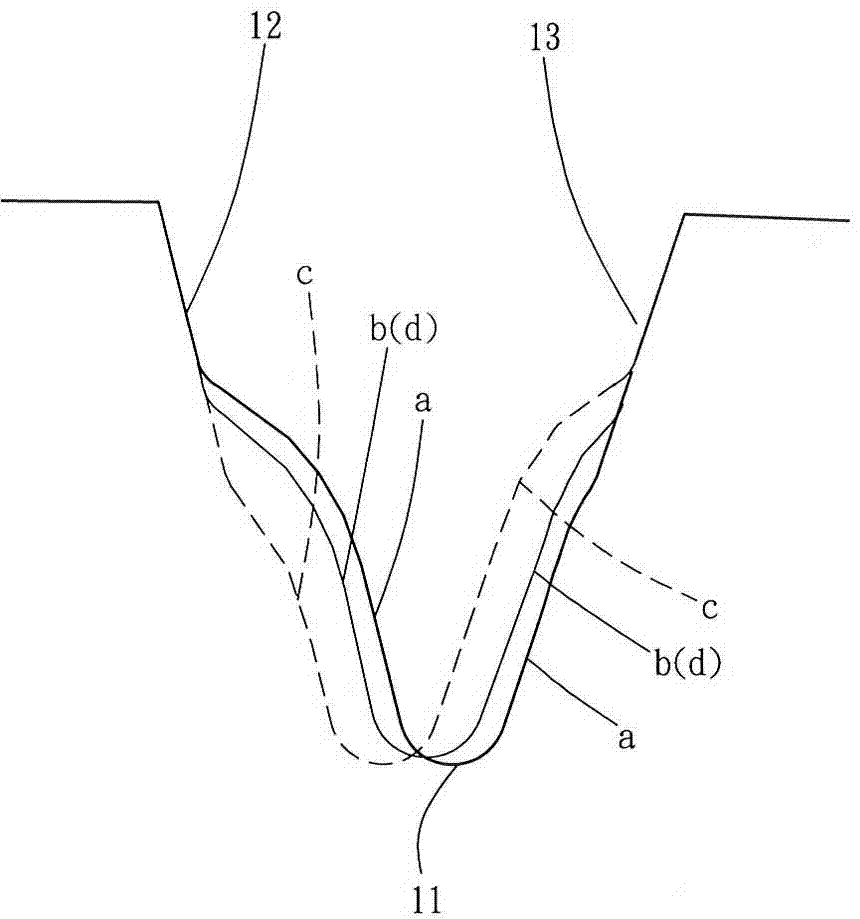

[0035] The sipe 10 is an open groove with a groove bottom 11 and two side edge walls extending to a preset height, and the two side edge walls are a first side wall 12 and a first side wall with a preset slope respectively Two sidewalls 13; the slopes of the first sidewall 12 and the second sidewall 13 are different, the edgewall near the center of the tire tread 50 is the first sidewall 12, and the edgewall near the shoulder The edge wall of 40 is the second sidewall 13 ; the inclination angle between the first sidewall 12 and the trench bottom 11 is larger than the inclination angle between the second sidewall 13 and the trench bottom 11 .

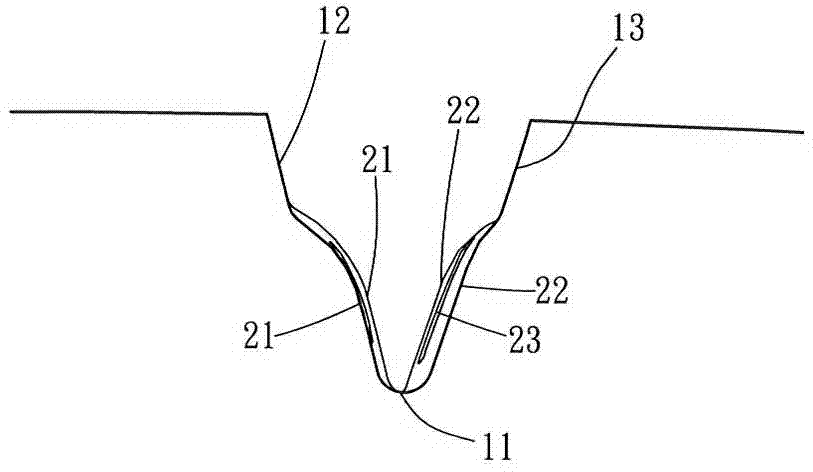

[0036]The convex step group 20 is arranged in the sipe 10, and has a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com