Hough hinge capable of adjusting level angle and lateral displacement of trolley

A technology of horizontal rotation and lateral displacement, applied in the field of half hinges, can solve the problems of difficulty in adjustment, difference in position and angle, cost and long period of rectification, so as to reduce the difficulty of adjustment, prevent the problem of rail gnawing, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

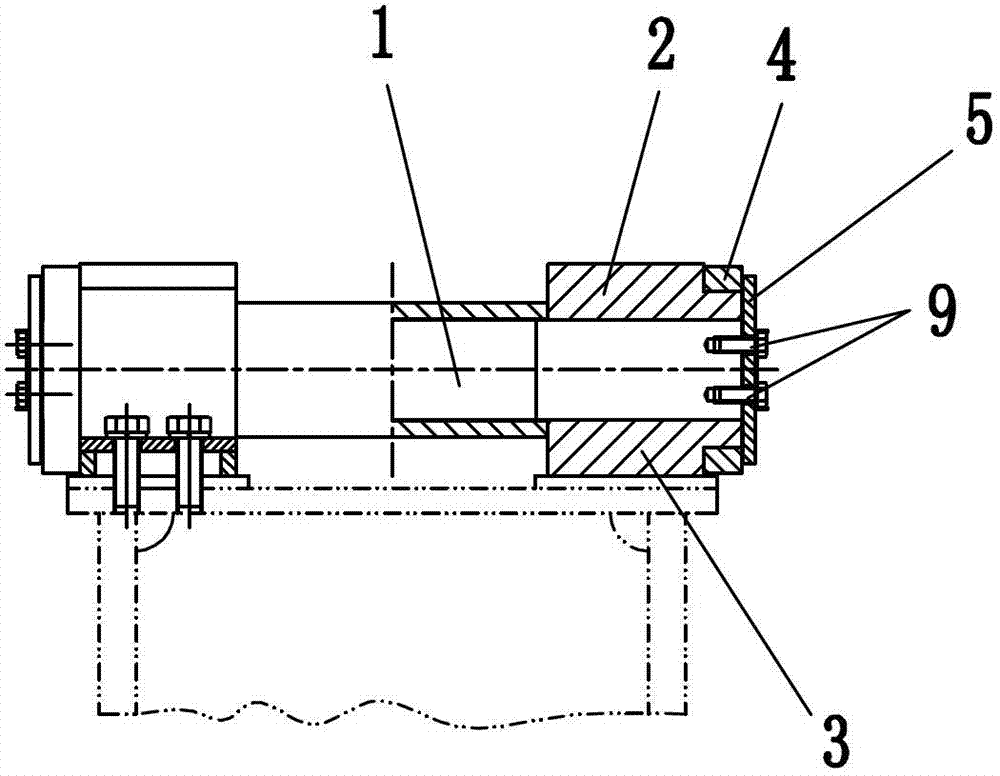

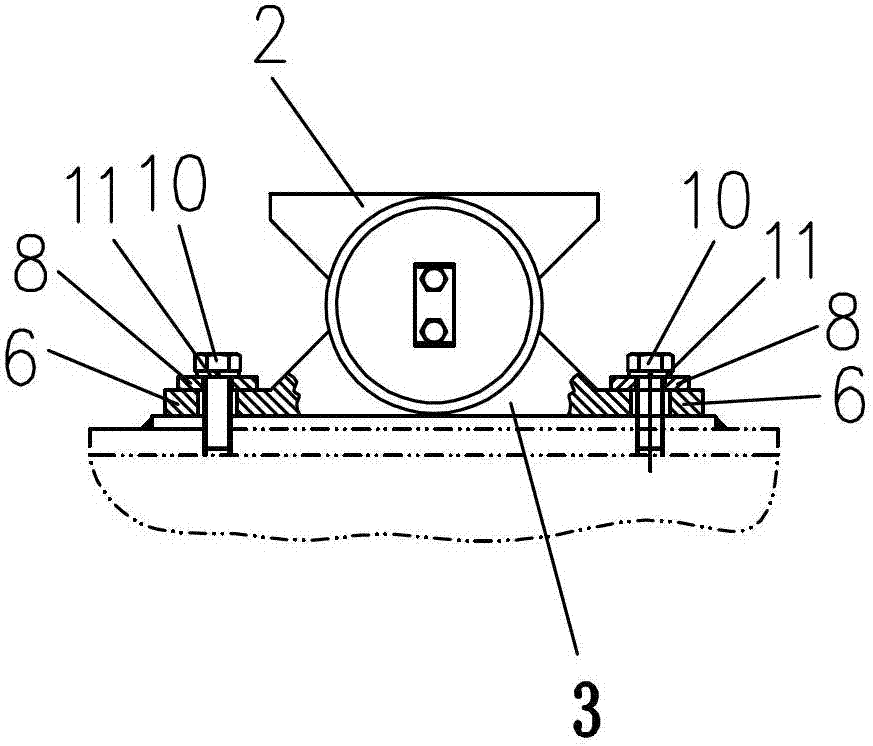

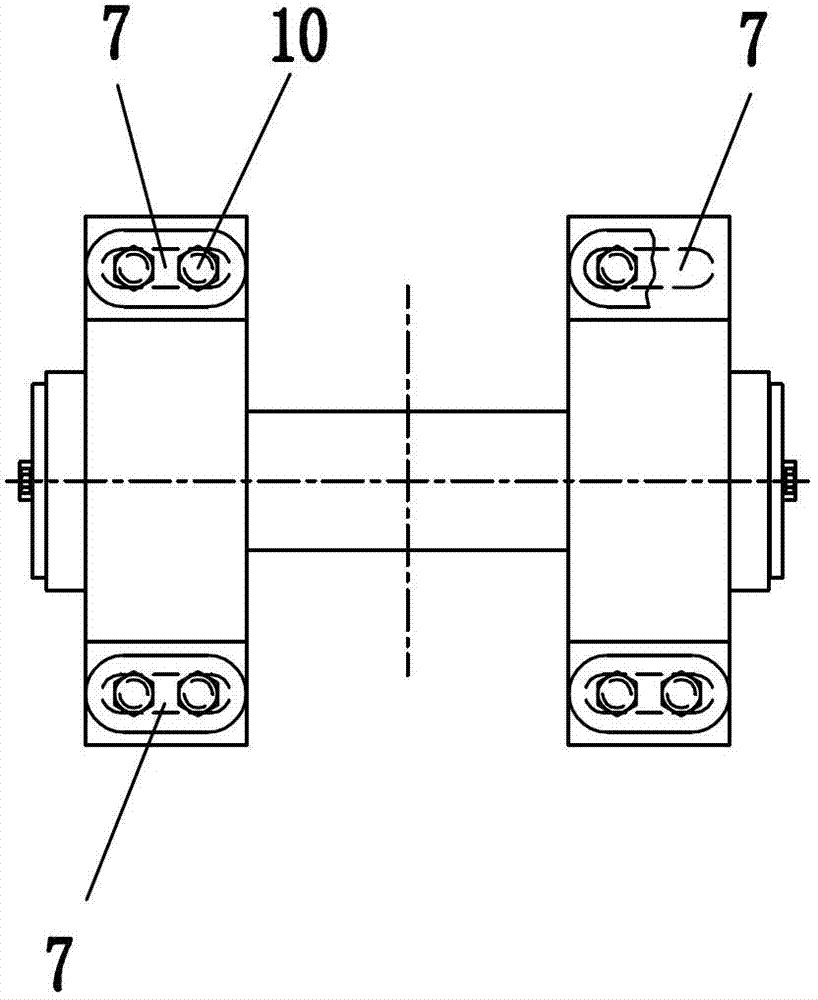

[0025] Such as Figure 1 to Figure 8 A Huff hinge 100 that can adjust the horizontal rotation angle and lateral displacement of the trolley shown in , includes a hinge shaft 1, and an upper hinge seat 2 and a lower hinge seat 3 are respectively arranged on the two ends of the hinge shaft, and the hinge shaft 1 is set In the upper hinge seat 2 and the lower hinge seat 3. The collar 4 is set on the outer ends of the upper hinge base 2 and the lower hinge base 3, so that the upper hinge base 2 and the lower hinge base 3 are fixed together, and the cover plate 5 is respectively fixed on the two ends of the hinge shaft 1 by bolts 9. The two sides of the bottom of the lower hinge seat extend radially outward respectively, and a side plate 6 is respectively provided on the two side plates 6 along the axial direction of the lower hinge seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com