Simulator stand for exhaust characteristics of vehicle engine

A technology for simulating test benches and vehicle engines, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., and can solve the problems of inability to simulate engine exhaust, inability to simulate exhaust pulsation, application limitations of simulation test benches, etc. problem, to achieve the effect of solving the insufficient noise intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

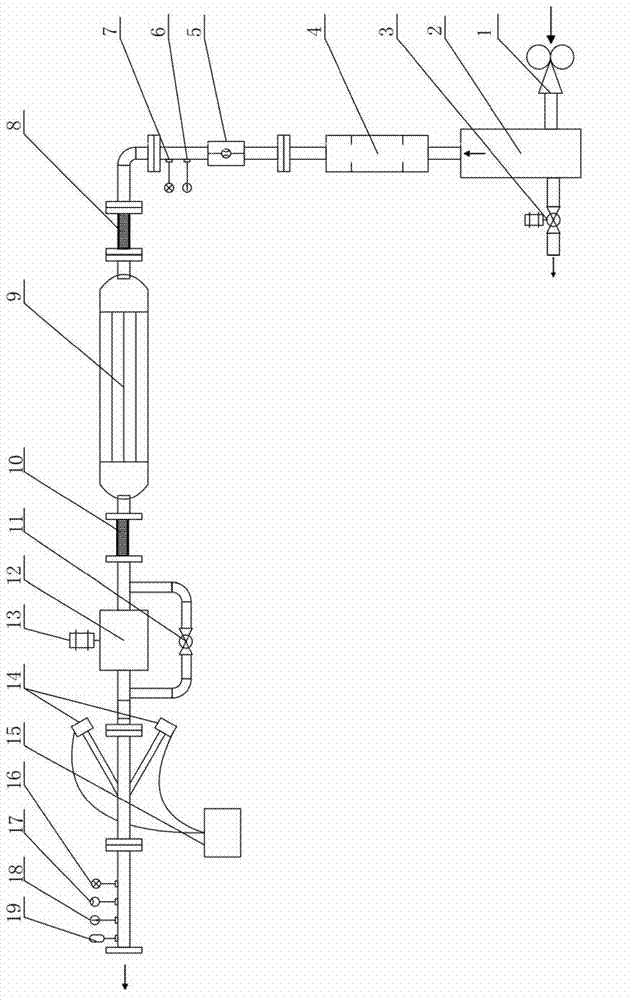

[0019] The vehicle engine exhaust characteristic simulation test bench that the present invention proposes, its structure is as follows figure 1 As shown, it includes air source, air intake measurement section, heating section, pulsation section, noise section and outlet measurement section. The air source, intake air measurement section, heating section, pulsation section, noise section and outlet measurement section are sequential Connected by pipes and flanges;

[0020] Wherein the gas source comprises blower fan 1, pressure stabilizing box 2, electric ball valve 3 and intake muffler 4, described stabilizing box 2 is provided with an air inlet and two air outlets, and the air inlet of stabilizing box 2 It is connected with the air outlet of the fan, and the bottom air outlet of the surge box 2 communicates with the atmospheric environment. The electric ball valve 3 is installed on the bottom air outlet of the surge box 2. The intake muffler 4 is connected;

[0021] Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com