Application of screened pigment to color fuming, fuming method and equipment for realizing fuming method

A pigment and color technology, applied in the field of colored smoke, can solve the problems of small proportion of active ingredients, unable to emit smoke normally, unfavorable wind direction, etc., and achieve the effect of increasing the proportion of active ingredients, avoiding the problem of different ignition and ignition time, and reducing pollution.

Active Publication Date: 2012-12-26

中国人民解放军69081部队防化修理所

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are three problems in such a method of generating smoke: first, the time from the start of ignition to the formation of pressure to spray out the smoke screen, that is, the so-called delayed ignition time, changes with the temperature. If the temperature is low, the time will be extended; if the temperature is high, the time will be shortened; There may even be cases where the temperature is too high to cause an explosion and cannot normally smoke, and the temperature is too low to ignite the smoke agent; second, the proportion of active ingredients in the product is small, such as a formula for pulling cigarettes on airplanes, and the compound dye in the purple smoke agent 59%; dyes in blue smokers accounted for 57%; dyes in red smokers accounted for 46%; dyes in yellow smokers accounted for 29%

Third, raw materials such as potassium chlorate and other toxic strong oxidants are used in large quantities in production

Fourth, once it is ignited, it cannot stop smoking halfway, even if there is an urgent need to stop smoking such as unfavorable wind direction

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030] Use ultra-fine powder, bright red red powder pigment as the smoke forming agent for the red smoke screen.

Embodiment 2

[0032] The light-yellow light-fast yellow G pigment in superfine powder form and bright shade is selected as the smoke-forming agent for the yellow smoke screen.

Embodiment 3

[0034] The phthalocyanine blue B pigment which is ultra-fine powder, bright in color and dark blue is selected as the smoke forming agent of the blue smoke screen.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

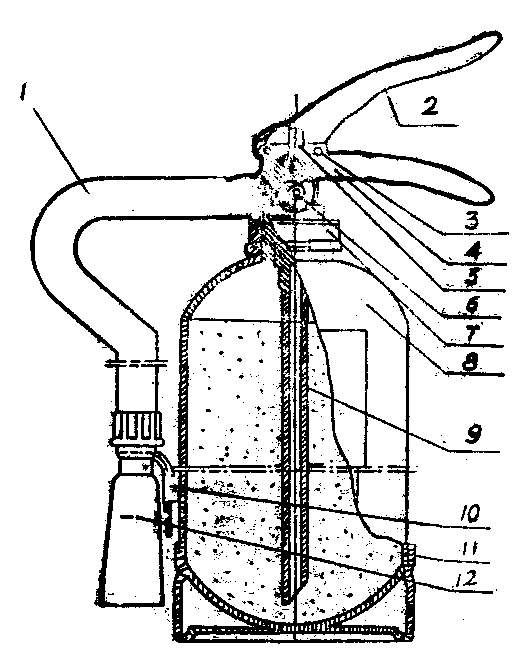

The invention relates to a novel application of a screened pigment to color fuming, a fuming method and equipment for realizing the method. According to the fuming method, a prepared fuming agent is a single pigment component or a mixture; during tank filling, compressed nitrogen is introduced; ignition is performed with a valve instead of a firing mechanism; and the fuming agent is not heated under the driving action of the pressure storing gas, and aerosol is formed directly and is discharged into the atmospheric air for forming colored smoke. The pigment is preferably pigment scarlet, hansa yellow G, phthalocyanine blue B or phthalocyanine green G. A fuming tank comprises a guiding tube, a pressure handle, a safety pin, a lifting handle, a thimble, a pressure gauge, a device head, a barrel, a powder absorbing tube, a guiding tube socket, a bottom ring and a nozzle. Due to the adoption of the color fuming method and fuming equipment disclosed by the invention, a fuming agent formula does not contain a large quantity of dangerous goods and toxic substances, fuming components are greatly increased, energy is saved, environmental protection is facilitated, and safety and reliability are realized; and the problem of different igniting time caused by different temperatures is solved, and fuming can be stopped at any time as required.

Description

technical field [0001] The present invention relates to the application of the screened paint pigment, especially in the field of color smoke. [0002] The invention relates to a fuming method of screened paint pigments, comprising pigment selection, filling steps, pressurizing steps and fuming steps. [0003] The invention also relates to an apparatus for implementing a screened method of fuming paint pigments. Background technique [0004] Colored smoke screens are widely used in the opening of festivals, celebration ceremonies, sports events, stage special effects, performing arts activities, aircraft smoke performances, and target indication. The commonly used color fuming pot is a sublimation type fuming pot, which is composed of an ignition mechanism, a smoking agent, and a tank body. Sublimation type fuming agents are generally composed of oxidizing agents, combustible agents and fumigants, and some also have binders. The oxidant mainly includes potassium chlorate ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A63J5/02

Inventor 徐云赵承进曾凡哲

Owner 中国人民解放军69081部队防化修理所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com