Method for adsorbing nitrogen oxides by use of mordenite

A technology of mordenite and nitrogen oxides, which is applied in the field of nitrogen oxides treatment, can solve the problems of secondary pollution, small adsorption capacity of adsorbents, unfavorable enterprise development, etc., and achieve small usage, high adsorption efficiency, and good recycling benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

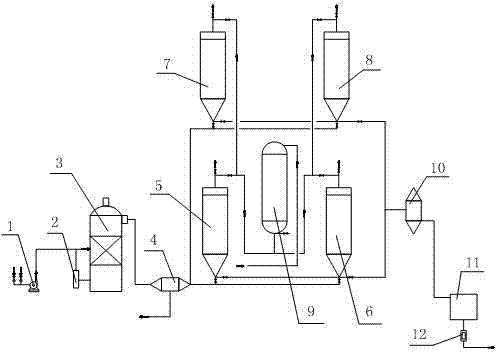

[0036] Such as figure 1 As shown, the system using mordenite to adsorb nitrogen oxides includes a pretreatment system, an adsorption-desorption system, and a cooling collection system connected in sequence.

[0037] The pretreatment system includes a fan 1, an acid pump 2, a cooling tower 3 and a wire mesh filter 4; wherein the fan 1, the cooling tower 3 and the wire mesh filter 4 are connected in sequence, and the acid pump 2 is connected to the bottom of the cooling tower 3 , and connect the fan 1 to the pipe net leading to the cooling tower 3 at the same time, and the wire mesh filter 4 communicates with the adsorption and desorption system. The acid pump 2 extracts the acid generated inside the cooling tower 3, cleans the waste gas conveyed by the fan 1, and removes impurities such as dust in the waste gas. The acid in the cooling tower 3 is formed by dissolving part of the waste gas in water, and collects at the bottom of the cooling tower 3 , the acid pump 2 is used to ...

Embodiment 2

[0055] The catalytic reduction method is now used in the market to treat nitric acid tail gas more thoroughly, but it consumes expensive metal platinum and produces a lot of ammonia, and the nitrogen oxides in the tail gas have not been recycled. The price of metal platinum is more than 550 / yuan per gram, Platinum metal is used as a catalyst to treat nitric acid tail gas. Due to the large amount of tail gas and the long-term process, the use of platinum metal is large, the cost of treatment is high, and it is easy to cause water pollution. The ammonia produced is dissolved in water to obtain ammonia water. Its volatility, the risk of explosion, can not be effectively treated, prone to air pollution, nitrogen oxides are not recovered, always exist in the tail gas, did not achieve the fundamental purpose of treatment, is not conducive to the development of enterprises, and the use of the present invention , can absorb the nitrogen oxides in the tail gas, and finally convert it in...

Embodiment 3

[0057] The liquid absorption method is relatively simple, but the absorption efficiency is only 60-70%. Most nitrogen oxides are insoluble in water or other liquids, so there is no way to absorb them. However, the absorption efficiency is 98% when using mordenite. The content of nitrogen oxides in the exhaust gas meets the national air emission standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com