Automobile anti-skidding wheel plate

A technology of anti-skid wheels and roulettes, applied in the direction of auxiliary wheels/rings, etc., which can solve problems such as shortened service life, reduced driving speed, car body damage and noise, etc., to achieve long service life, reduce hazards, and solve the effects of sideslip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and through specific embodiments, but the present invention is not limited thereto.

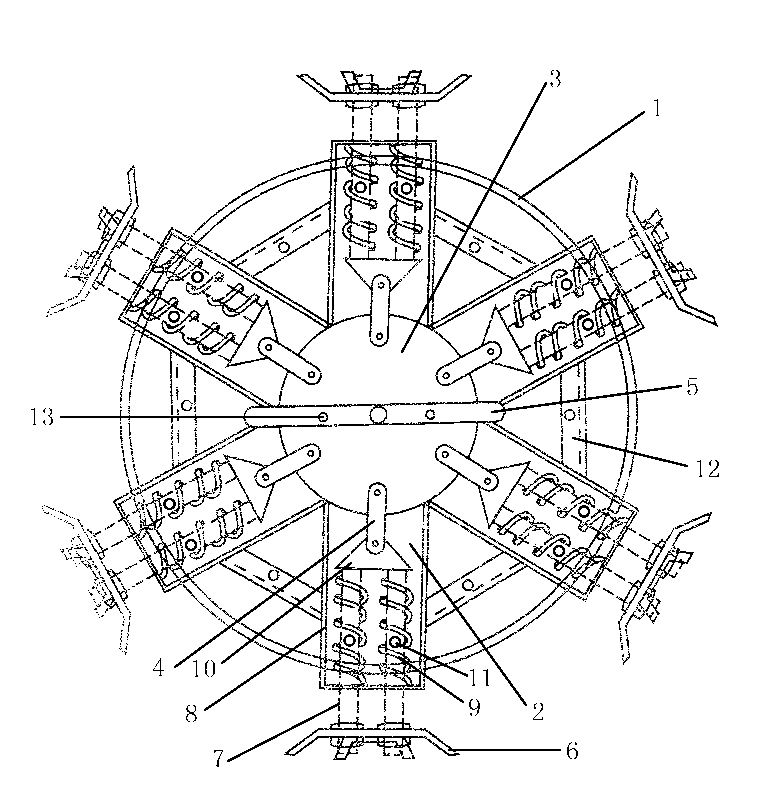

[0014] Such as figure 1 As shown, the present invention includes a circular wheel 1, six anti-skid teeth symmetrically distributed along the radial direction of the wheel, and an adjusting disc 3 at the center of the wheel. The circular wheel 1 is slightly larger than the diameter of the hub, and the anti-skid teeth shrink It is less than the outer diameter of the tire when it is back, and it is approximately equal to the outer diameter of the tire when it is stretched out; there are also interconnected reinforcing ribs 12 between the above-mentioned anti-skid teeth. Wherein the anti-skid teeth 2 are connected with the adjustment disc 3 through the adjustment connecting rod 4, and an adjustment handle 5 is also installed on the adjustment disc 3, and the rotation adjustment handle 5 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com