Steel structure connecting device of wood-stone composite bridge

A connecting device and composite bridge technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems such as collapse, structural damage, and ancient bridge surface shedding, and achieve the effect of extensive engineering application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

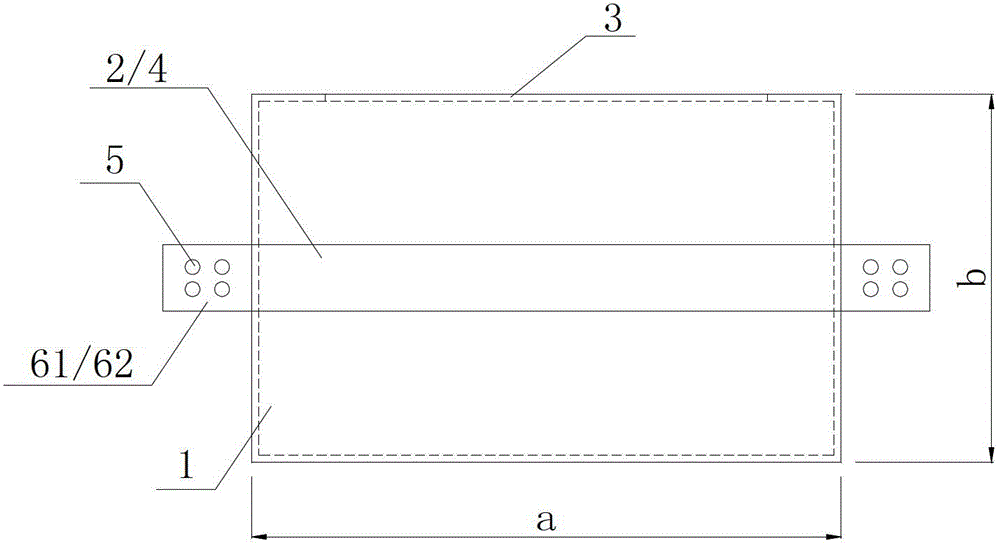

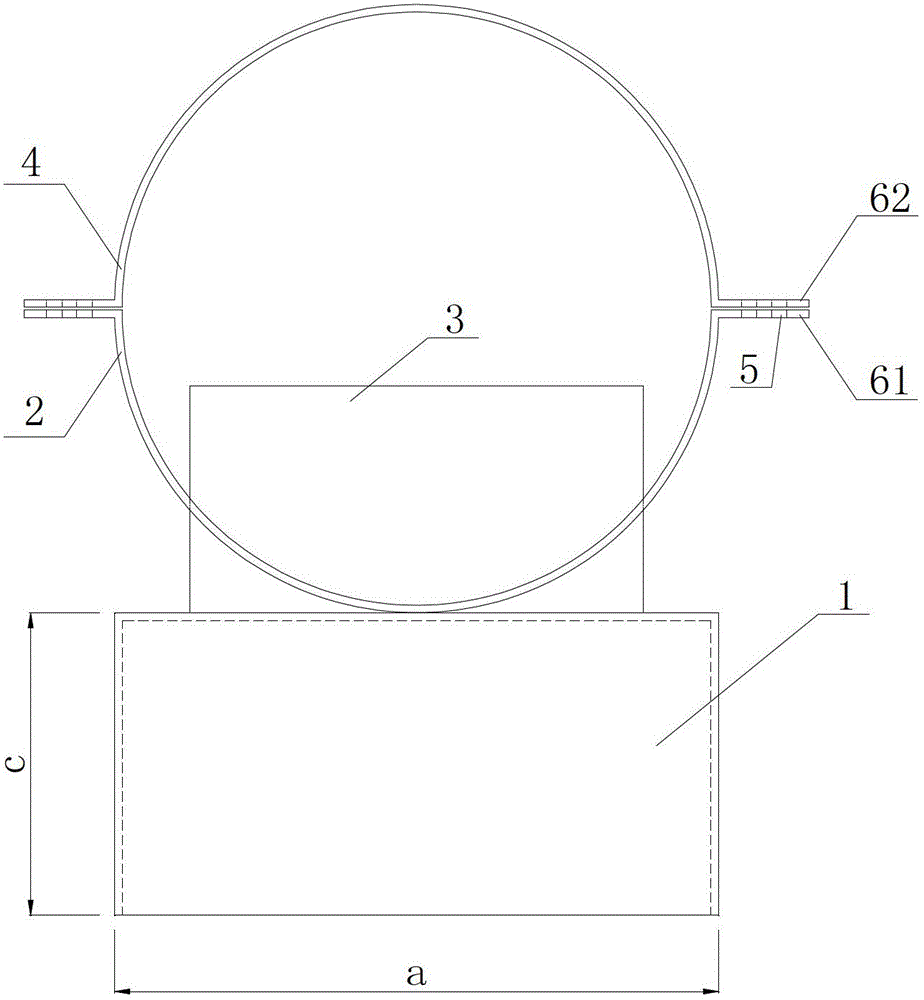

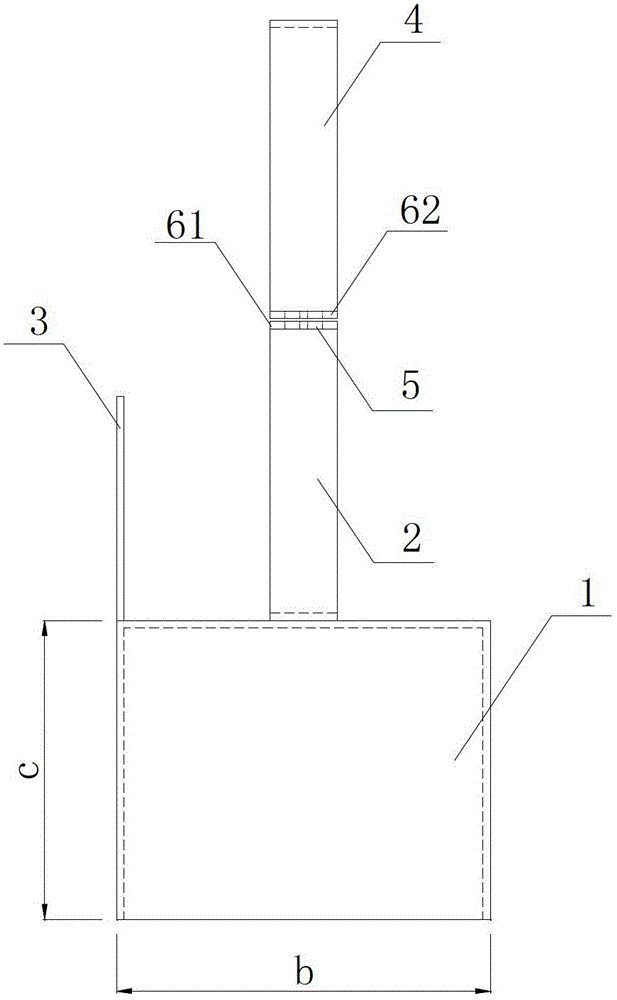

[0024] In order to achieve the purpose of firmly connecting the stone bridge pier and the log longitudinal beam, a steel cap is used to buckle the pier, and a semicircular arc-shaped steel plate with a radial end plate (the end plate has bolt holes) is welded on the cap Put the log stringer into the semi-circular arc-shaped steel strip, and then fix the other half of the semi-circular arc-shaped steel strip with radial end plate with the steel strip welded on the sleeve cap through bolts. The baffle plate is welded on the edge of the upper surface of the cap to prevent the longitudinal movement of the log, and the distance between the baffle plate and the semi-circular steel strip should be slightly greater than the protruding length of the log as its expansion joint. In this way, a longitudinal beam is built, and several longitudinal beams can be built as required, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com