Illuminating structure

A light-emitting structure and light-guiding member technology, which is applied in the direction of electric light source, light source fixing, lighting device, etc., can solve the problems of increasing the production cost of the known backlight module, increasing the cost of circuit board material required for circuit board width, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

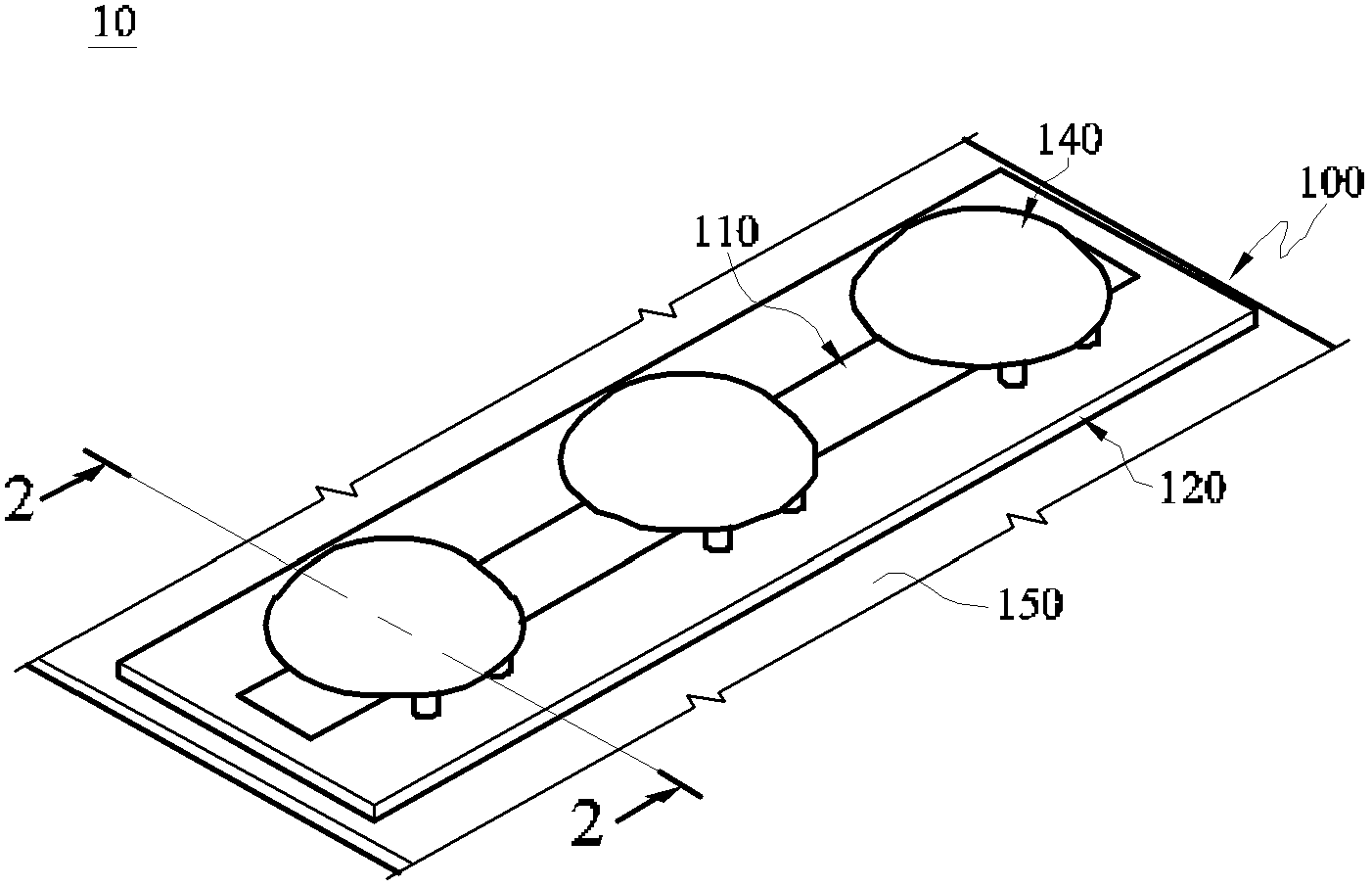

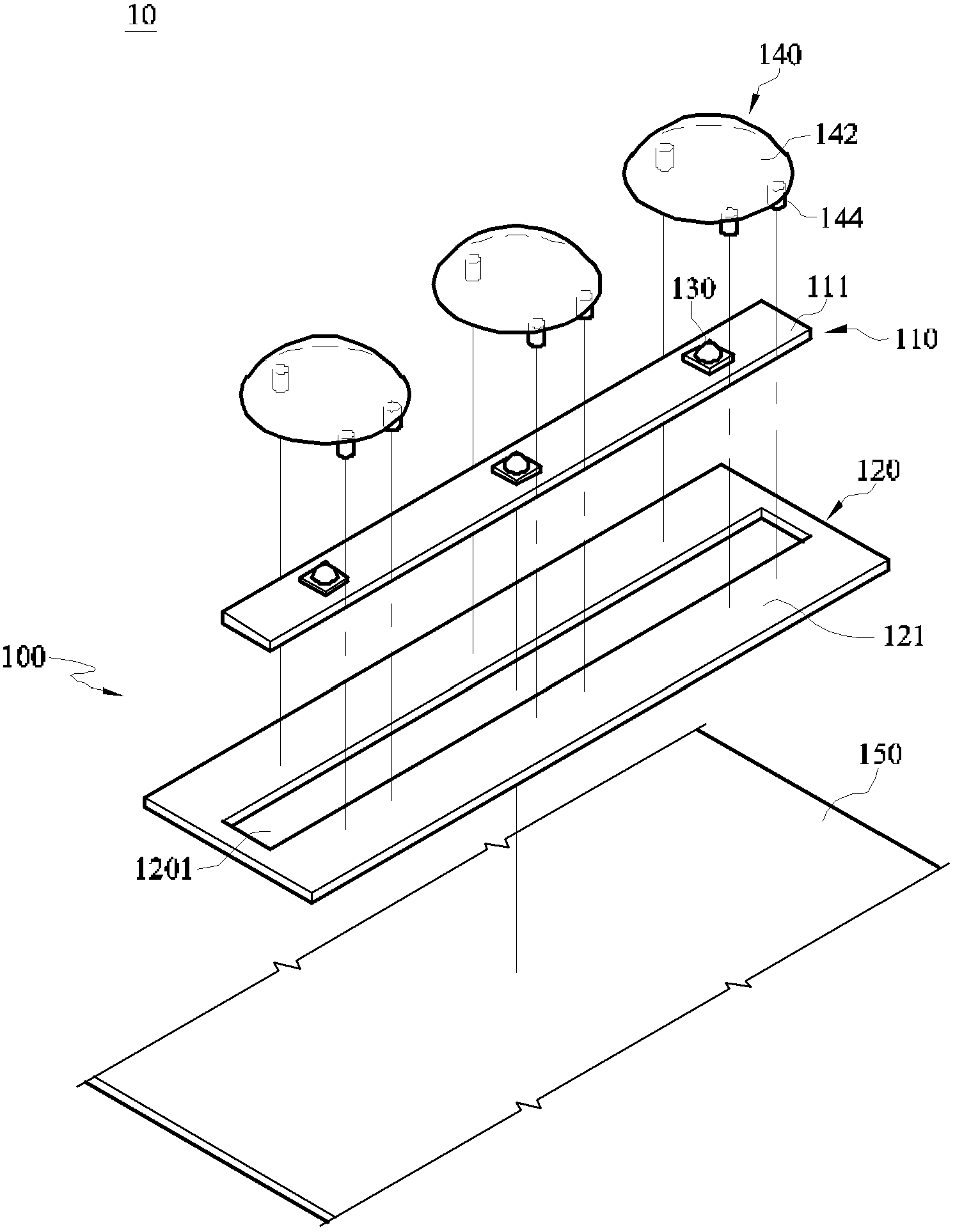

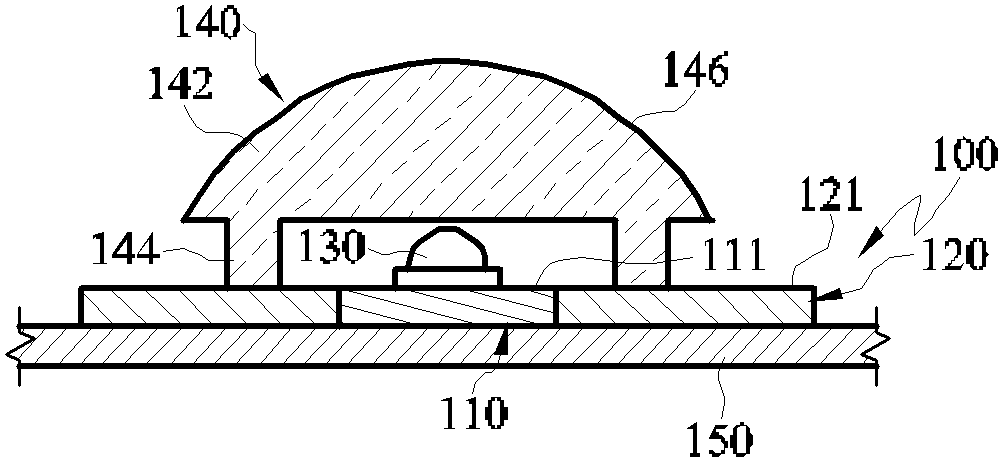

[0036] Please refer to Figure 1A , Figure 1B and figure 2 , Figure 1A It is a structural combination diagram of a light emitting structure according to an embodiment of the present invention, Figure 1B is a partially exploded view of a light emitting structure according to an embodiment of the present invention, figure 2 based on Figure 1A Sectional view of the 22 section line.

[0037] The light emitting structure 10 of this embodiment can be applied to a backlight module (not shown) of a display device (not shown), but not limited thereto. For example, the light emitting structure 10 of this embodiment can also be applied to lighting equipment in other fields.

[0038] The light emitting structure 10 includes a substrate assembly 100 , at least one light source 130 and at least one light guide member 140 . The illustration of this embodiment takes three light sources 130 and three light guide members 140 as examples, but the numbers of the light sources 130 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com