Extruding die of double color line

A technology of extruding molds and colored lines, which is applied to mark the direction of conductors/cables, etc., and can solve the problems that the outer surface of the cable cannot be extruded evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

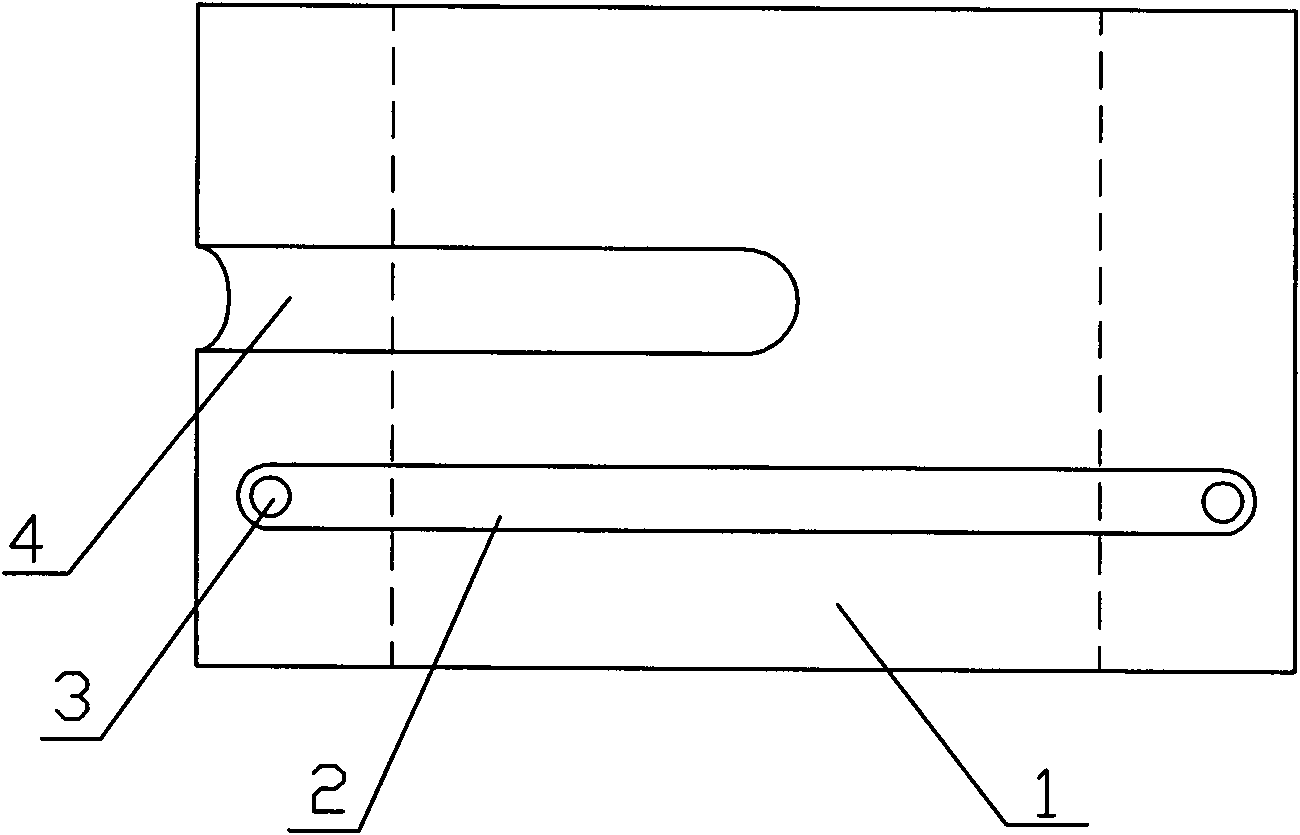

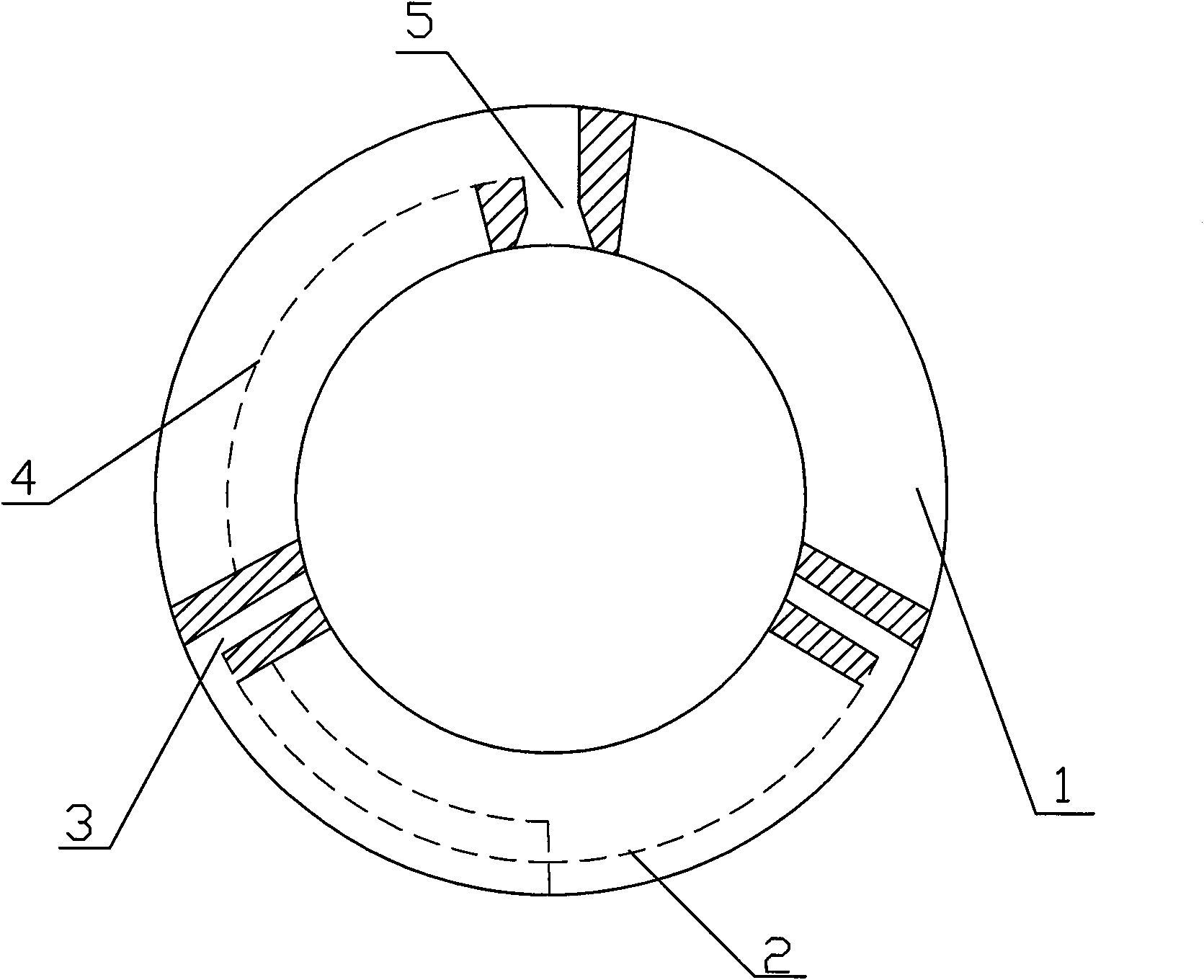

[0011] exist figure 1 Among them, a 120° short annular groove 2 and a 180° long annular groove 4 are arranged on the outer surface of the mold body 1 respectively, and a hole 3 is respectively provided at both ends of the short annular groove 2, and the long annular groove One end of 4 is located above the middle position of the short annular groove 2, and the other end of the long annular groove 4 is provided with a horn-shaped hole 5, and the depth dimension of the long annular groove 4 is correspondingly larger than that of the short annular groove 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com