Improved structure of wiring terminal

An improved structure and terminal technology, applied in the direction of contact parts, clamping/spring connection, etc., can solve problems such as poor contact, loose overall structure, insufficient clamping force, etc., to improve the clamping force of shrapnel and increase the overall structural strength , The effect of stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

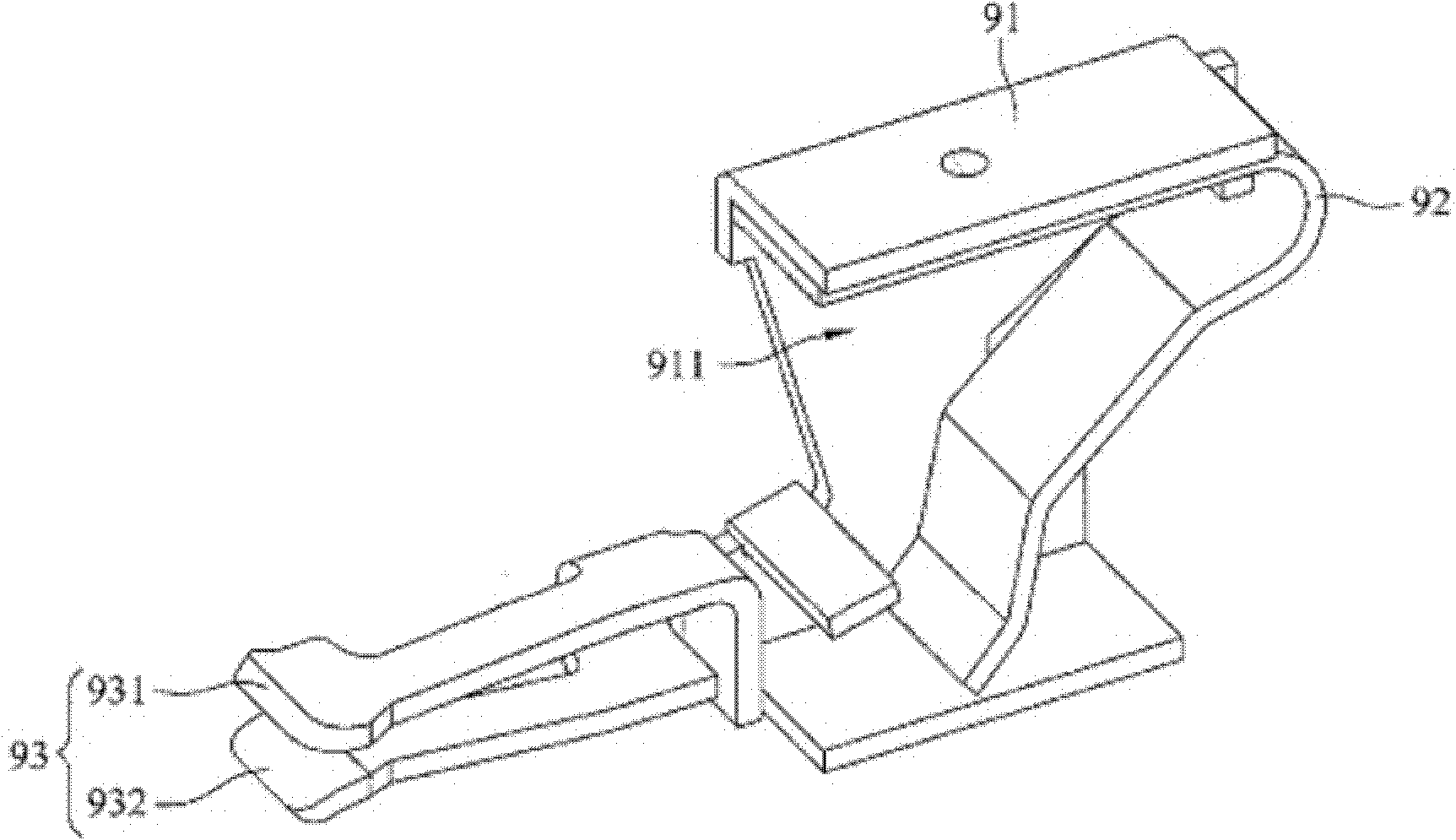

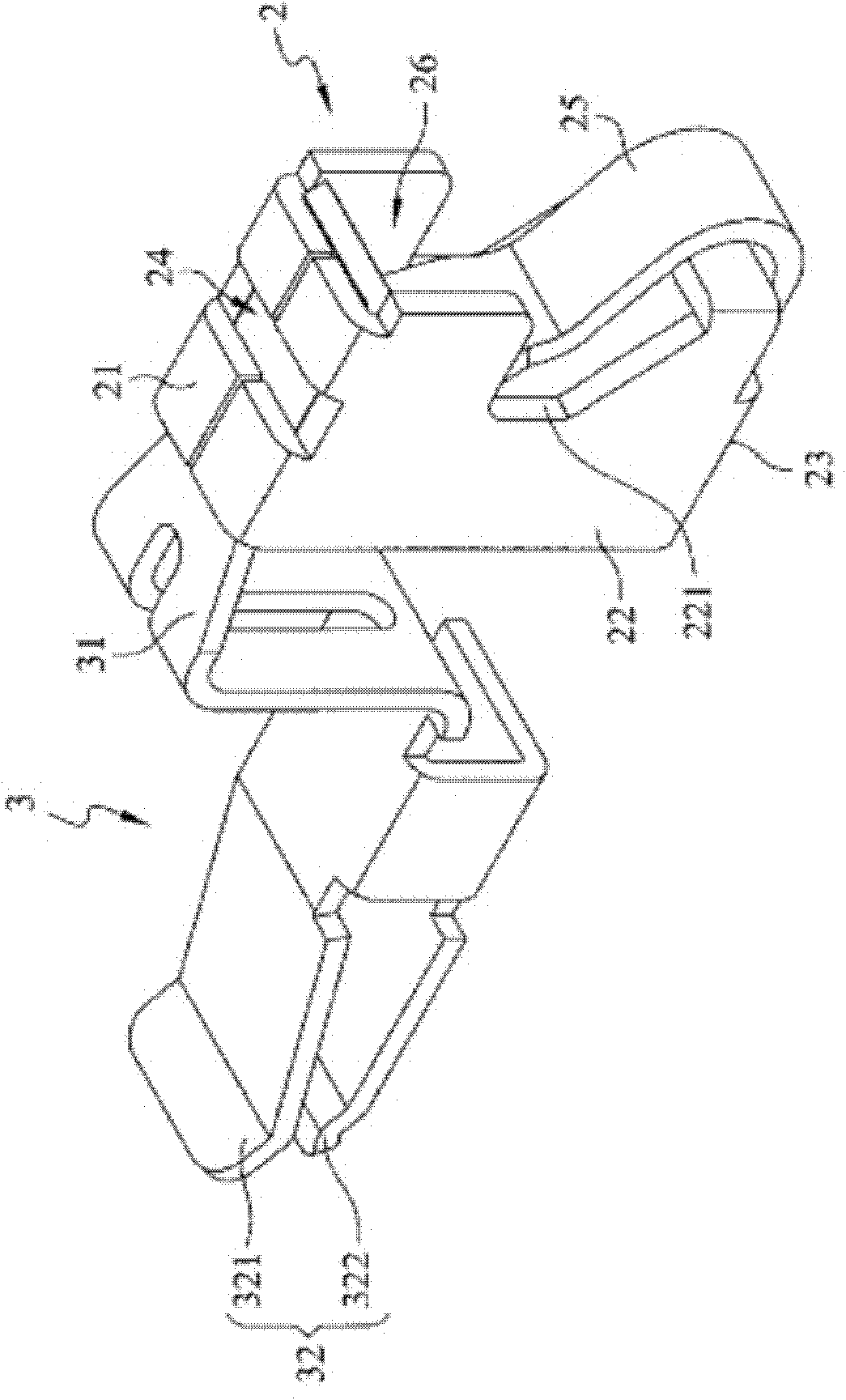

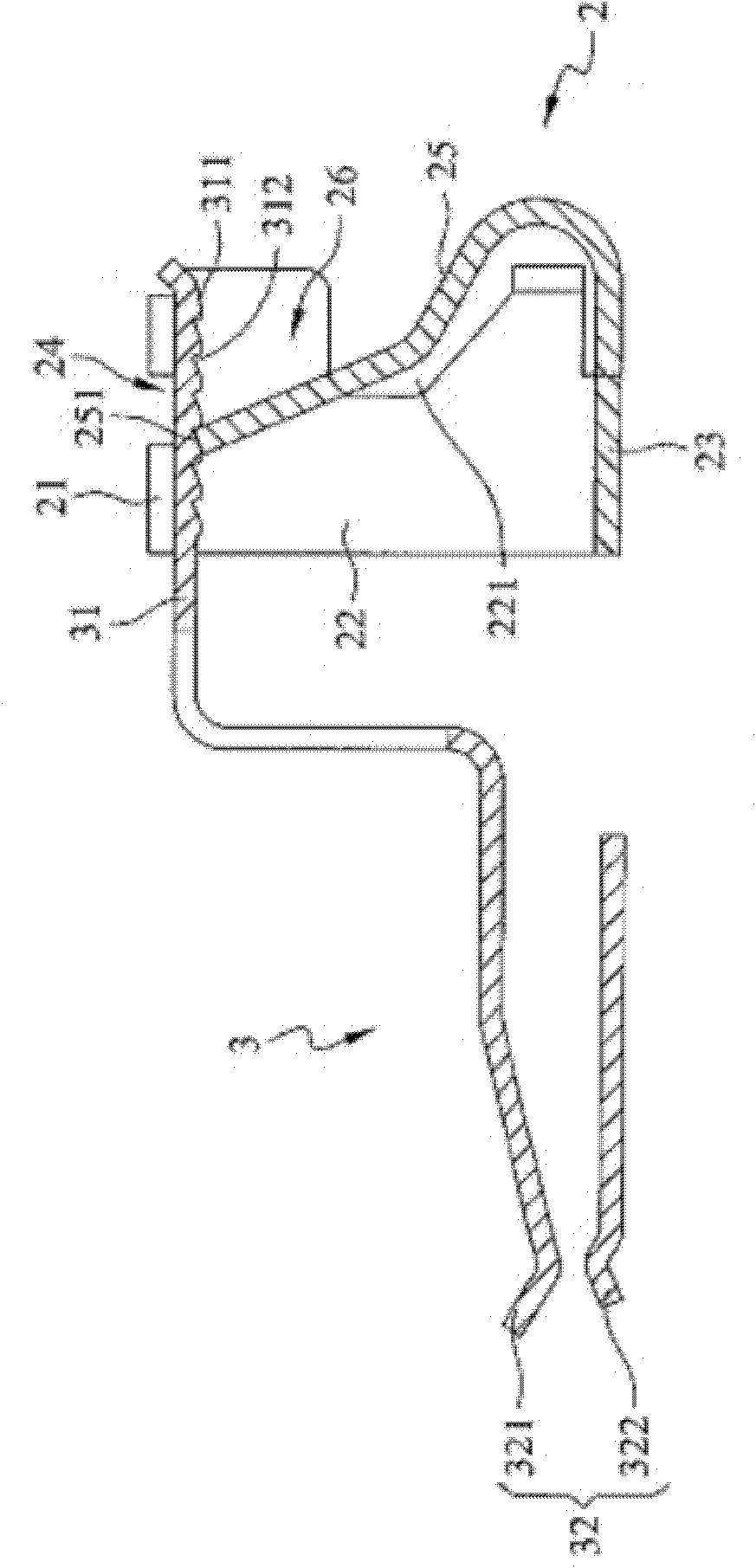

[0019] like figure 2 , image 3 , Figure 4 and Figure 5 As shown, the improved structure of the connection terminal of the present invention includes a box body 2 and a plug connector 3 .

[0020] The box body 2 is an integral molding and includes an upper wall 21, two side walls 22, a lower wall 23, a hole 24 and a shrapnel 25, the upper wall 21, the two side walls 22 and the lower wall 23 are connected to each other and Surrounding a space 26, the hole 24 is opened on the upper wall 21 and communicates with the space 26 and the outside of the box body 2. The elastic piece 25 extends upward from the lower wall 23 to the space 26 and extends with an end 251, and the end 251 protrudes from the upper wall 25. The hole 24 of wall 21 (such as Figure 5 shown).

[0021] In this embodiment, the section of the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com