Installation method for balance weight

An installation method and a technology of balance weights, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low safety, potential safety hazards, damage to the host and failure to operate normally, and achieve the effect of avoiding loosening and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The practical application of the present invention is illustrated below with the installation of the balance weight of the low-speed marine diesel engine of the 5S60ME-C type.

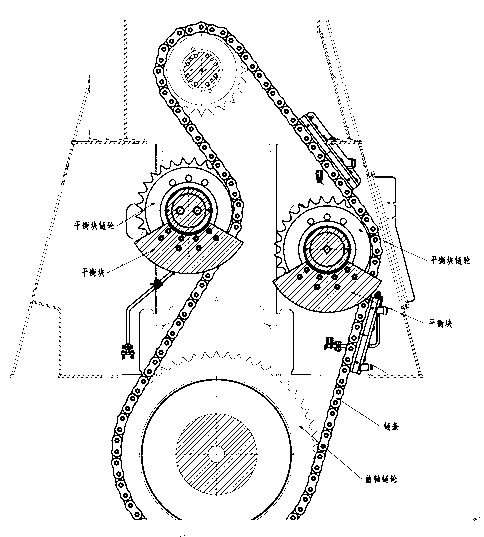

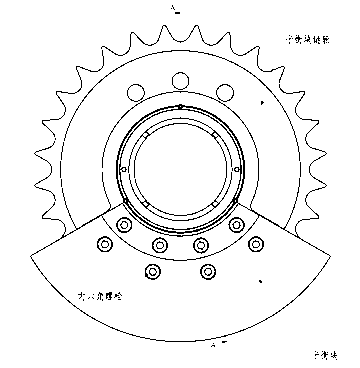

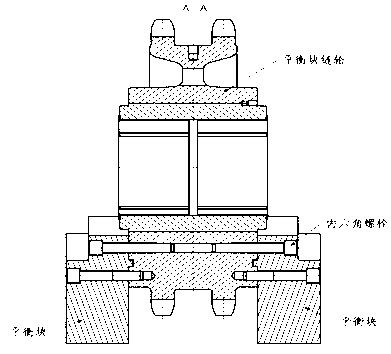

[0027] Such as figure 2 As shown, the original balance weight installation method is to use hexagon socket bolts to connect the balance weight and the balance weight sprocket. Such as image 3 As shown, the original balance weight structure is suitable for hexagon socket bolt connection.

[0028] Such as Figure 4 As shown, the installation method of the balance weight of the present invention is to use the outer hexagonal bolt to connect the balance weight and the balance weight sprocket, and then lock it with a locking wire, see Figure 6 . Such as Figure 5 As shown, in order to match the new installation method, the structure of the new balance weight has been changed. At the same time, in order to keep the original moment of inertia unchanged, UG modeling analysis was applied to desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com