Butt end bracket for long-distance transport of large-scale wind power generation blades

A technology for wind power generation blades and long-distance transportation, which is applied in the directions of transportation and packaging, external frame, packaging, etc., can solve the problems of blocking and cracking of deformed inner and outer nuts, avoid deformation and blocking cracking, and improve the replacement efficiency and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

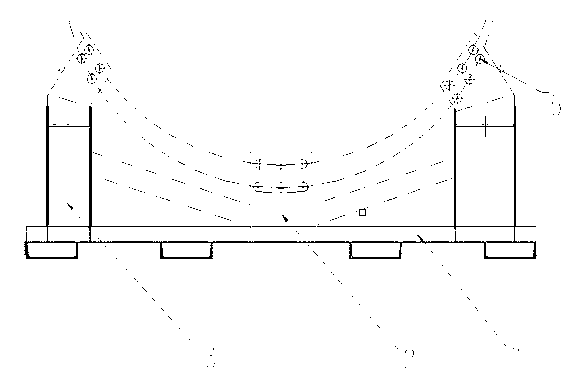

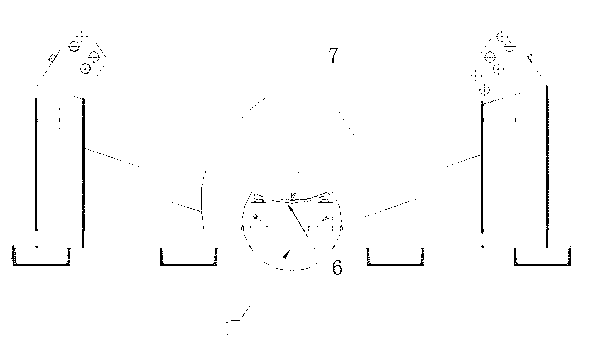

[0009] like figure 1 , figure 2 As shown, a root end bracket for long-distance transportation of a large-scale wind power generation blade according to the present invention is mainly composed of a blade root end bracket base 1, a blade load-bearing rod 2, a blade load-bearing rod 3, a hydraulic jack mechanism 4, a bolt hole 5, It is composed of supporting plate 6 and rubber pad 7; the two ends and the center of the blade root end bracket base 1 are respectively provided with blade load-bearing rods (2, 3), and the blade load-bearing rods (2, 3) are divided into upper and lower groups. Bolt holes 5 that can meet two different specifications, quantities, and distributions of different types of wind turbine blade root bolts that can meet the same circumference diameter, height, and position are processed; 5. The wind turbine blade is fixed on the blade load-bearing rod (2, 3) through the cooperation of the hole shaft. The hydraulic jack mechanism 4 is installed at the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com