Middle trough and scraper conveyor applied to full-seam mining in extremely thick coal seams

A technology of scraper conveyor and extra-thick coal seam, which is applied in the field of middle trough and scraper conveyor to achieve the effect of satisfying space layout and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

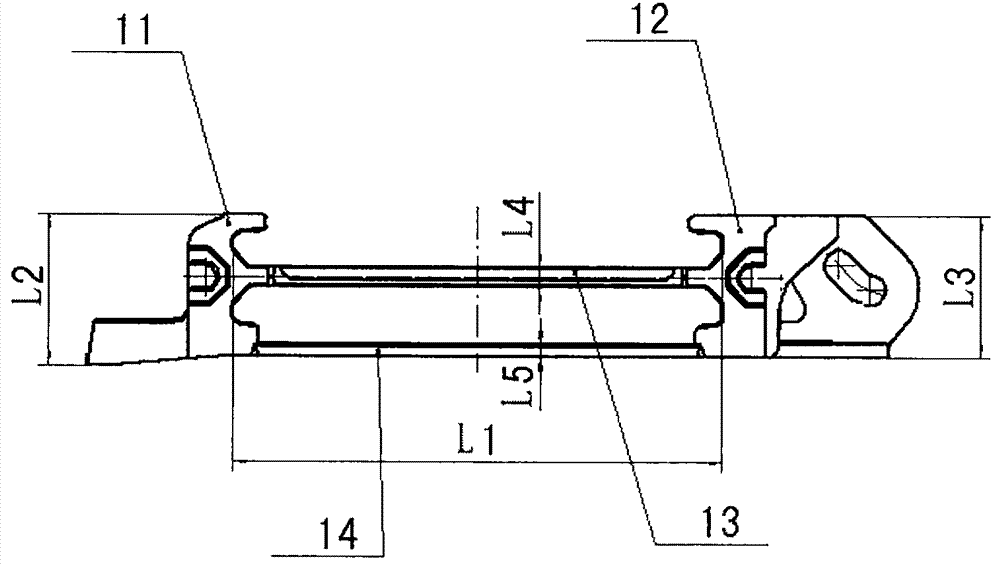

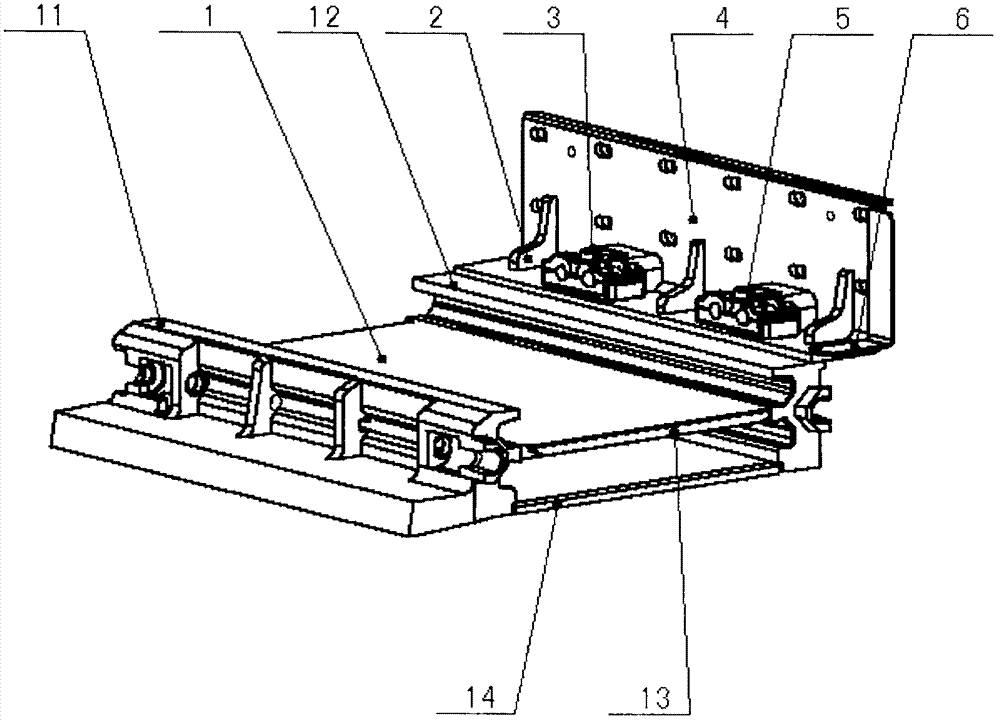

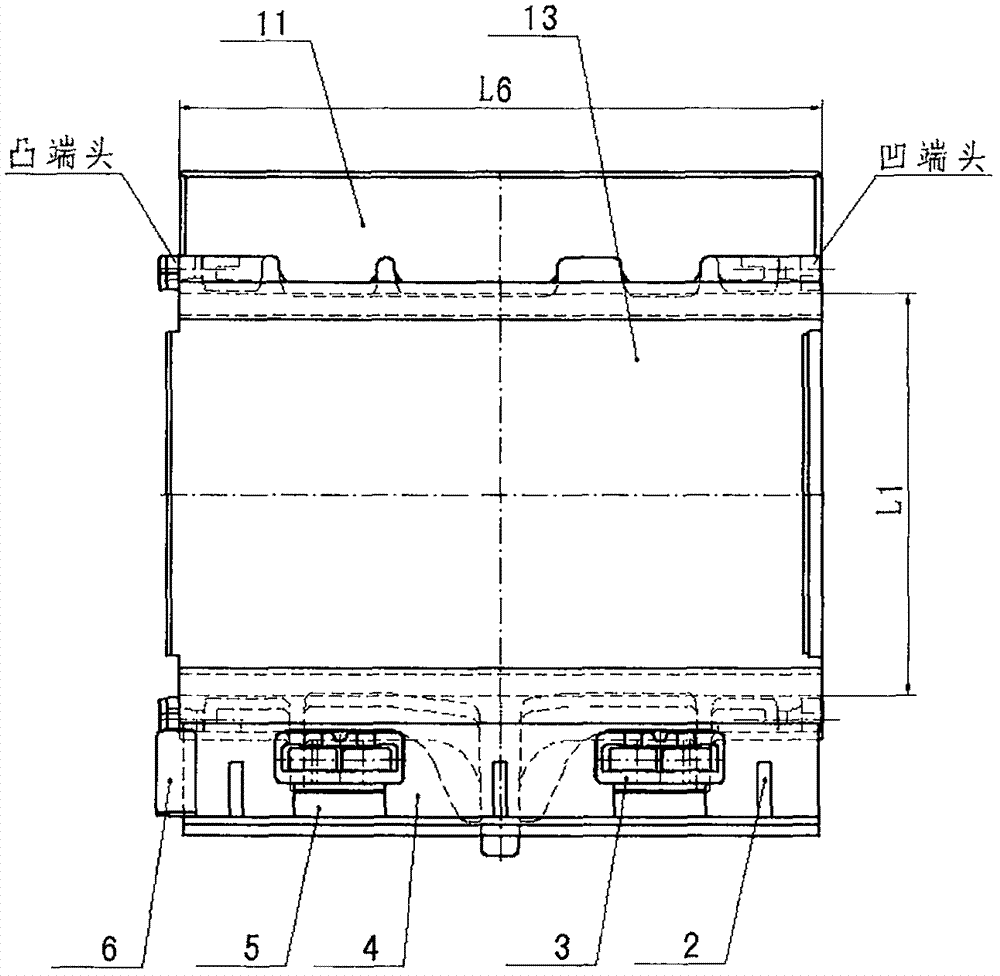

[0030] Among them: 1. Middle tank body, 2. Rib plate, 3. Left rail seat assembly, 4. Bending plate assembly, 5. Right rail seat assembly, 6 Lap joint plate, 7. Pin rail, 8. Cylindrical pin, 9. Limiting pin, 10, cable groove, 11, "∑" type shovel plate groove side, 12 "∑" type baffle plate groove side, 13, middle plate, 14, base plate.

[0031]

[0032] The invention provides a middle groove of a scraper conveyor, such as Figure 1~3 As shown, the middle tank body 1 is a cast-welded bottom sealing structure, including: "∑" type shoveling side 11, "Σ" type baffle side 12, middle plate 13, and bottom plate 14. The middle 13 plate is located above the bottom plate 14 , and provided with intervals, the "∑" type shovel side is pivotally connected to the left side of the middle plate 13 and the bottom plate 14, and the "Σ" type baffle side is pivotally connected to the right side of the middle plate 13 and the bottom plate 14. The "∑" type shovel side 11 and the "∑" type baffle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com