Paper feeding device

A paper feeding and paper separating technology, which is applied in the direction of transportation and packaging, object separation, pile separation, etc., can solve the problems of overloading the paper feeding motor system, increasing the load on the paper taking motor, and increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

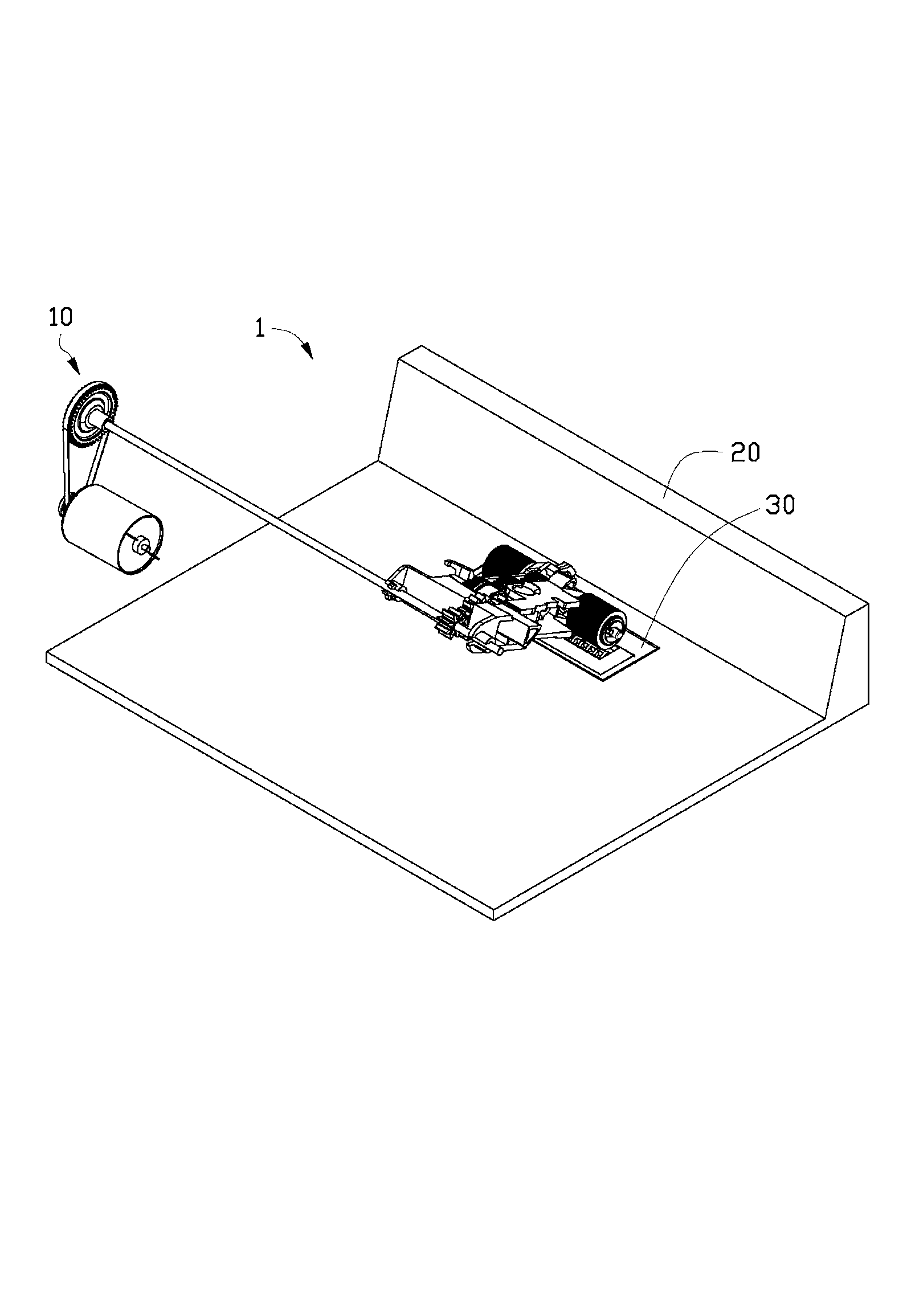

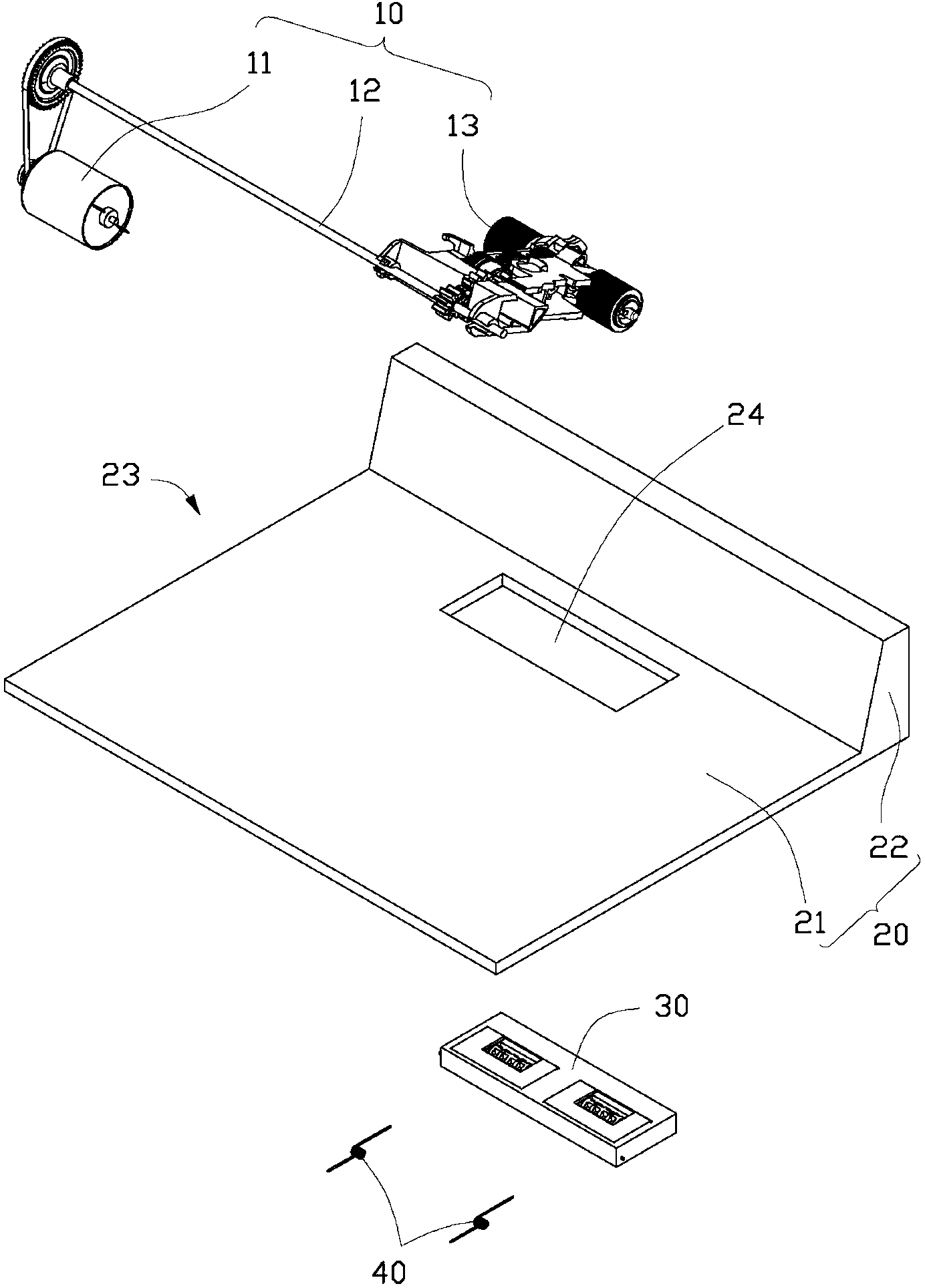

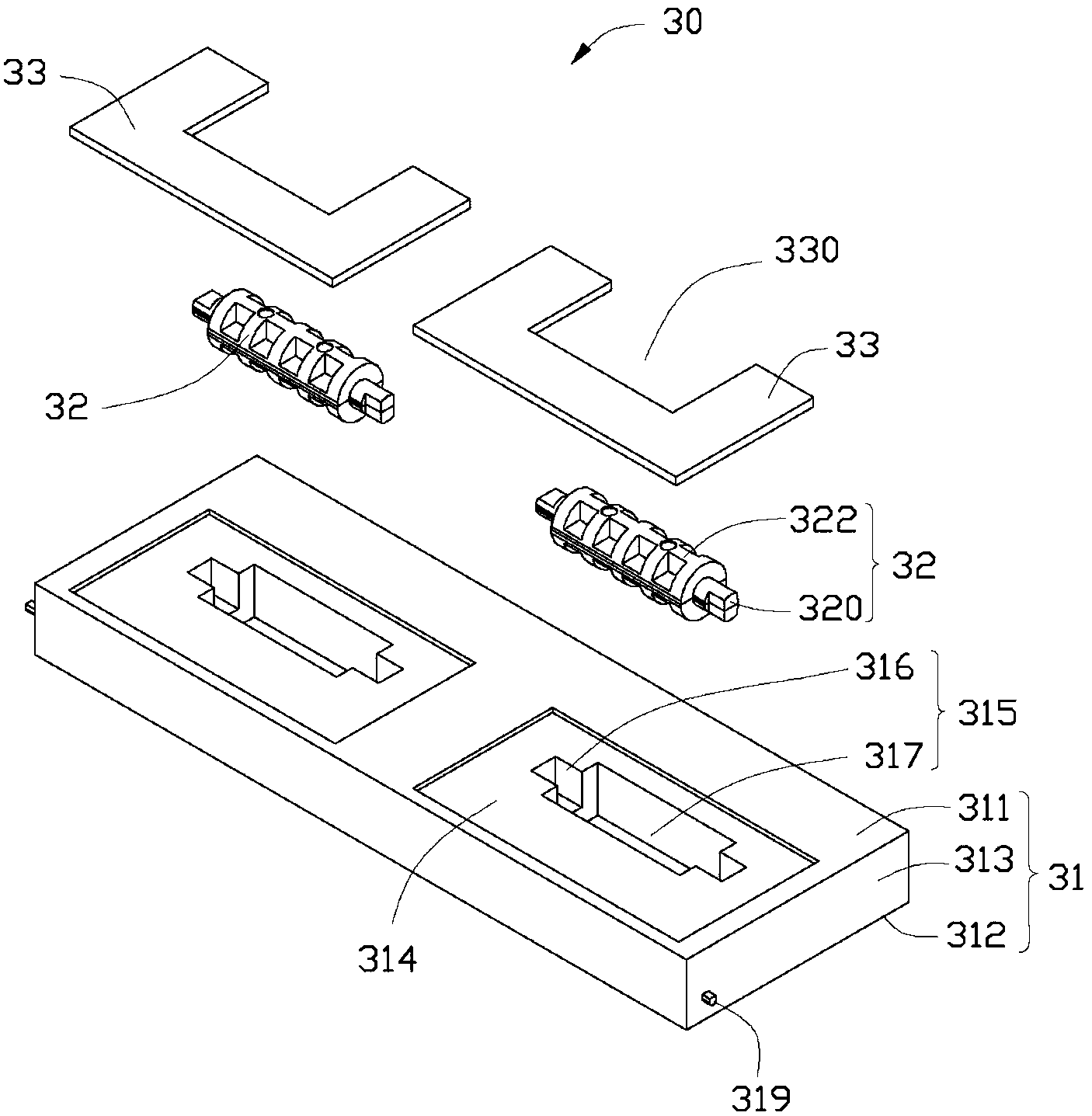

[0016] Please also refer to figure 1 and figure 2 , is a perspective view and an exploded view of the paper feeding device 1 in a preferred embodiment of the present invention. The paper feeding device 1 includes a driving mechanism 10 , a paper feeding box 20 , a paper separating mechanism 30 and an elastic member 40 . The paper tray 20 includes a supporting plate 21 and a blocking plate 22 protruding from one side of the supporting plate 21 . A mounting hole 24 is defined through the support plate 21 . The paper separation mechanism 30 is rotatably fixed in the installation hole 24 . The driving mechanism 10 includes a motor 11 , a transmission mechanism 12 and at least one friction wheel 13 pressing on the paper separation mechanism. The motor 11 and the transmission mechanism 12 are used to jointly drive the friction wheel 13 to rotate. The paper is put in from the baffle 22 and slides between the paper separating mechanism 30 and the friction wheel 13 , and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com