Device and method for synthesizing fullerene structure nanometer WS2 and application of fullerene structure nanometer WS2

A technology of fullerene structure and synthesis device, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of inability to continuously prepare in large quantities, difficult to operate, difficult to discharge, etc., and achieve easy control, amplification, and reaction. The effect of short time and simple bed type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

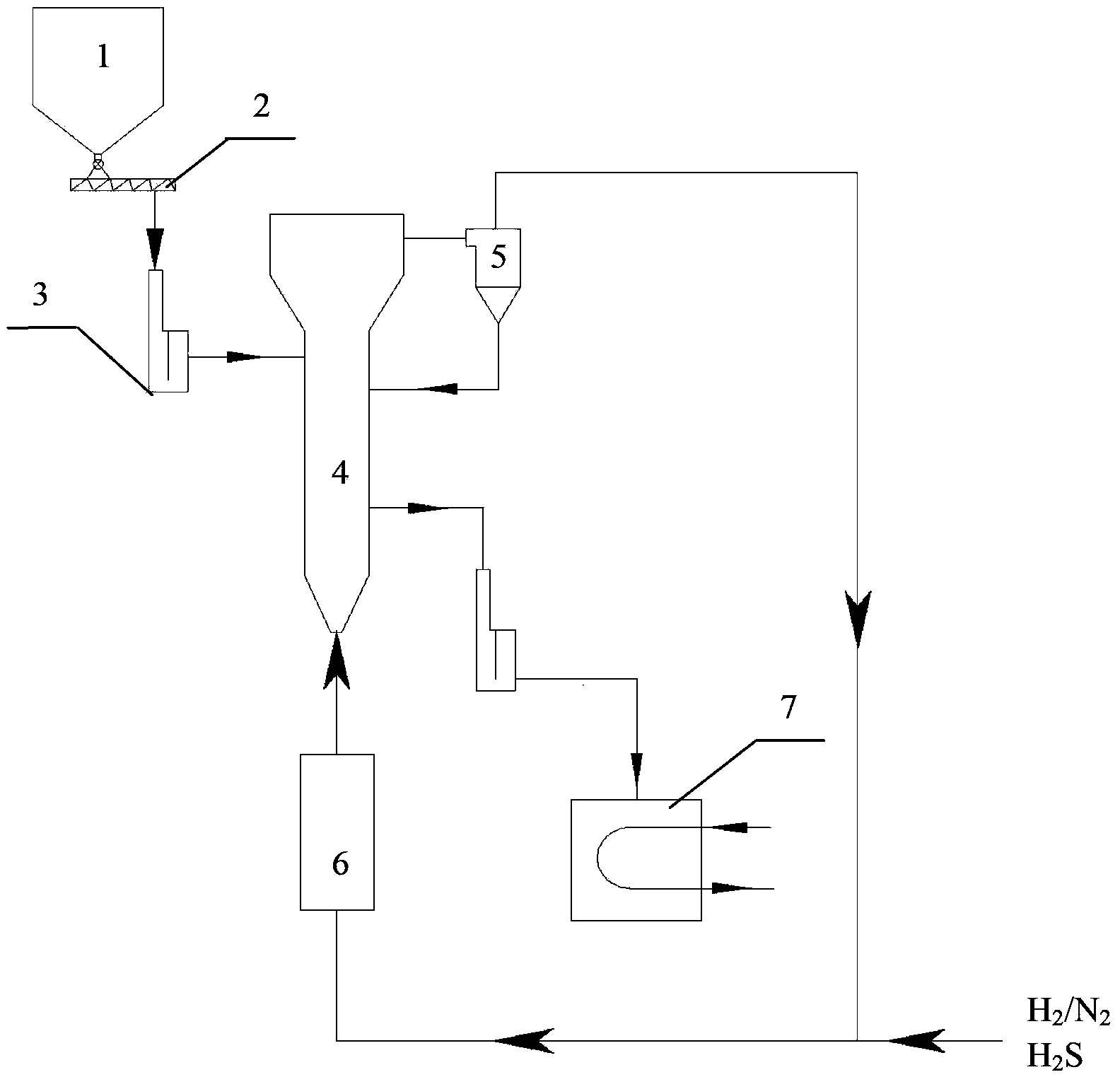

[0033] Embodiment 1 A kind of fullerene structure nano WS 2 synthesis device

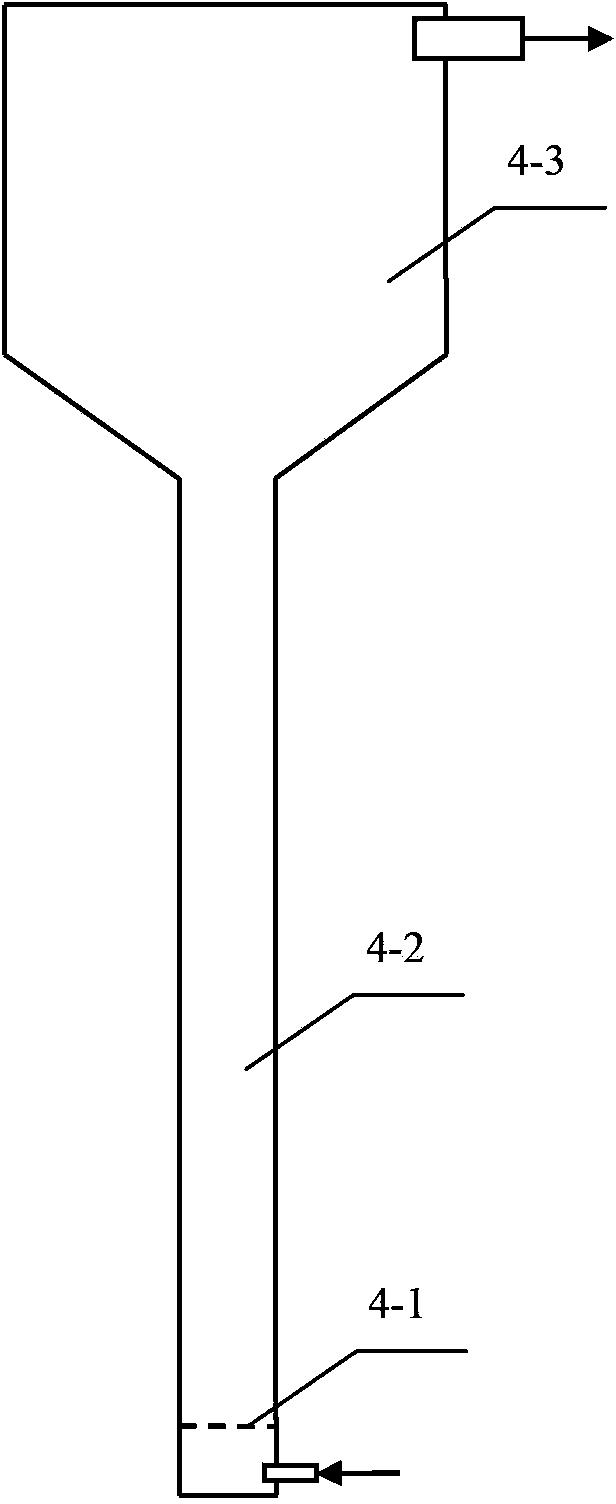

[0034] like figure 1 As shown, the device comprises a feed system, a fluidized bed reactor 4 and a cooling system 7 connected in sequence, and an air inlet is provided at the bottom of the fluidized bed reactor 4. The fluidized bed reactor 4 includes a gas distribution plate 4-1, a lower dense-phase bed 4-2 and an upper dilute-phase bed 4-3 from bottom to top. The outlet of the fluidized bed reactor 4 is connected to a cyclone separator 5 , and the bottom of the cyclone separator 5 is connected to the fluidized bed reactor 4 .

[0035] The feed system includes a feed bin 1 and a screw feeder 2 below the feed bin 1 ; the screw feeder 2 is connected to a fluidized bed reactor 4 through a feed valve 3 . A discharge valve is provided between the fluidized bed reactor 4 and the cooling system 7 . The gas inlet at the bottom of the fluidized bed reactor 4 is connected with the preheater 6, and the pre...

Embodiment 2

[0038] use as figure 1 The synthesized fullerene structured nano-WS shown 2 Process device diagram, in which the opening ratio of the gas distribution plate of the fluidized bed reactor is 1%, and the diameter of the lower layer dense-phase bed is 0.5 times the diameter of the upper layer dilute-phase bed.

[0039] The specific operation steps are as follows:

[0040] Nano-WO with a particle size of 20 nm 3 The powder is sent into the fluidized bed reactor 4 through the feed system, and the 2 , N 2 and H 2 The mixed gas of S is the raw material gas. The raw material gas is passed into the preheater 6 for preheating. The temperature of the preheated raw material gas is 500°C. The preheated raw gas passes through the gas distribution plate from the inlet at the bottom of the fluidized bed. 4-1 is evenly passed into the fluidized bed reactor 4, so that the WO in the fluidized bed reactor 4 3 The powder is in a fluidized state. Feed gas and WO in fluidized bed 3 The powder...

Embodiment 3

[0043] use as figure 1 The synthesized fullerene structured nano-WS shown 2 Process device diagram, in which the opening ratio of the gas distribution plate of the fluidized bed reactor is 0.5%, and the diameter of the lower dense-phase bed is 0.18 times the diameter of the upper dilute-phase bed.

[0044] The specific operation steps are as follows:

[0045] Nano-WO with a particle size of 100 nm 3 The powder is sent into the fluidized bed reactor 4 through the feed system, and the 2 , N 2 and H 2 The mixed gas of S is the raw material gas. The raw material gas is passed into the preheater 6 for preheating. The temperature of the preheated raw material gas is 500°C. The preheated raw gas passes through the gas distribution plate from the inlet at the bottom of the fluidized bed. 4-1 is evenly passed into the fluidized bed reactor 4, so that the WO in the fluidized bed reactor 4 3 The powder is in a fluidized state. Feed gas and WO in fluidized bed 3 The powder is full...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com