Mud filter pressing experimental device

An experimental device and mud technology, which are applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of unfavorable teaching experiments, high equipment cost, complicated operation, etc., and achieve simplified filter press structure and convenient operation. , the effect of intuitive observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

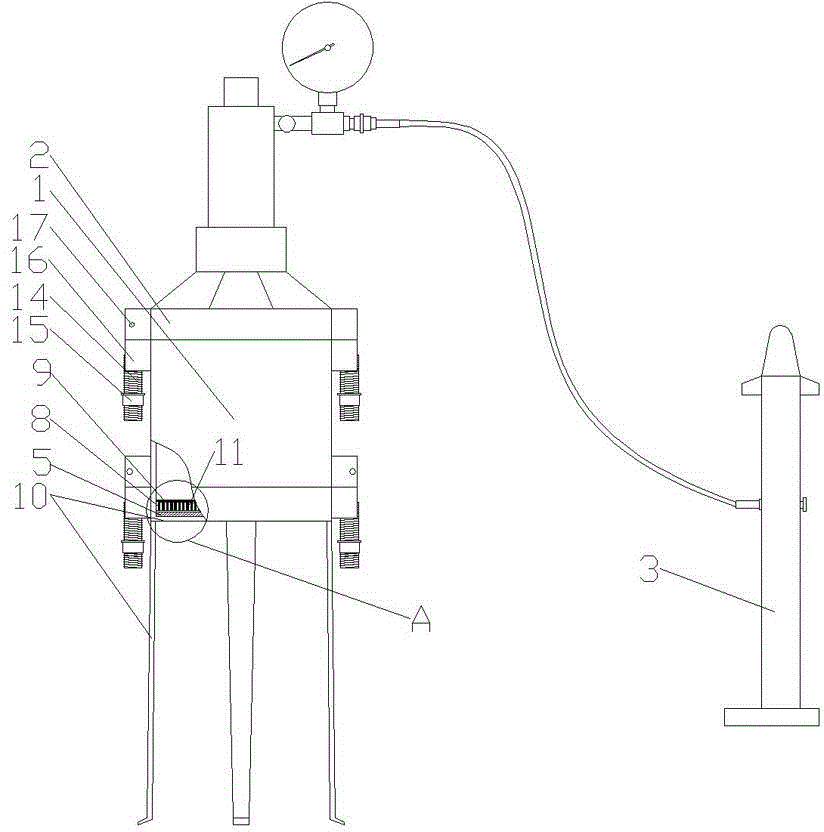

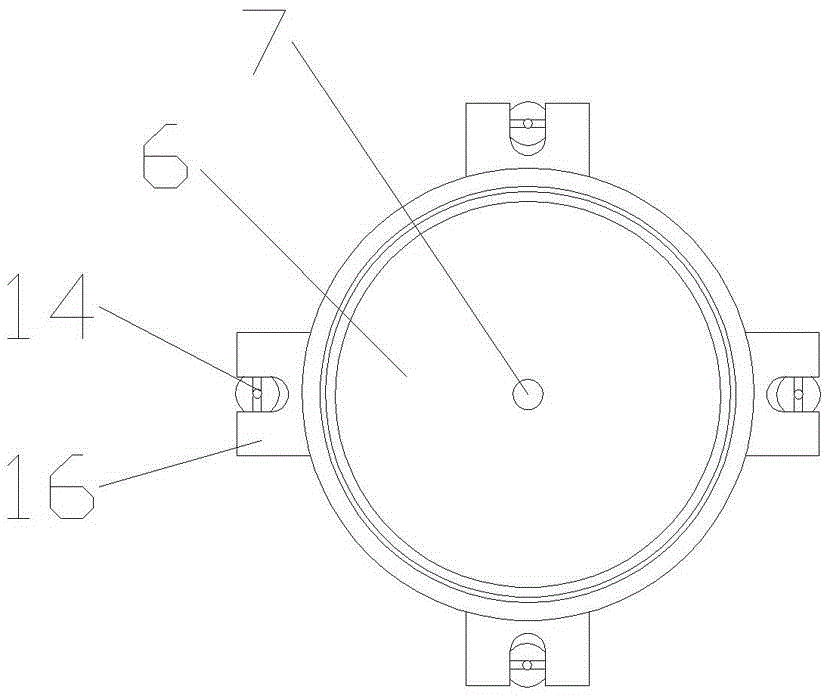

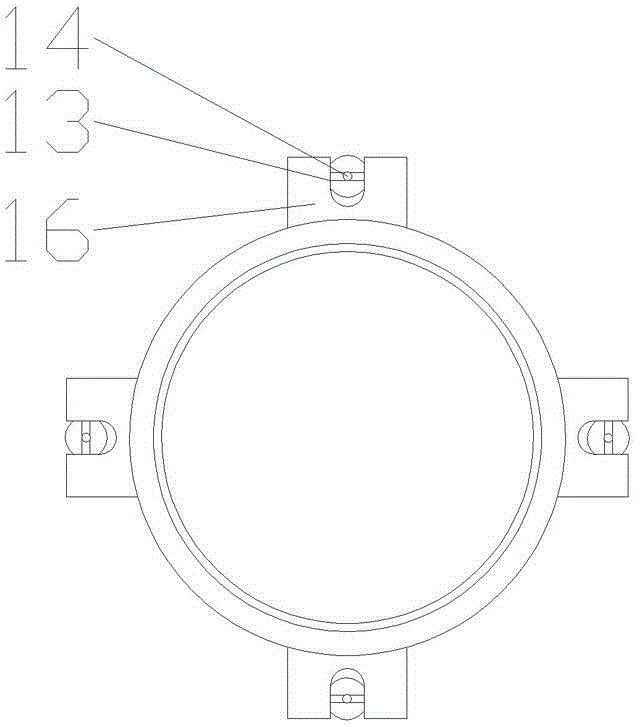

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the mud filter press experiment device provided by the present invention includes a filter press cylinder 1, and a filter press cover 2 is arranged on the upper end of the filter press cylinder 1, and the filter press cover 2 is connected with a pressurizing device 3, and inside the filter press cylinder 1 Equipped with a piston, the filter press cylinder 1 and the filter press cover 2 are jointly equipped with a first locking device, the lower end of the filter press cylinder 1 is equipped with a base 5, the base 5 has a mounting groove 6, and the bottom of the mounting groove 6 has a drainage hole 7, a metal filter plate 8 with a filter hole 11 is set in the installation groove 6, a filter cloth 9 is placed on the metal filter plate 8, a second locking device is configured on the base 5 and the filter press cylinder 1, and the base 5 is set on the stand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com