Telescoping operating arm, operating device and injection moulding device

A manipulation device and injection molding technology, applied in the direction of claw arms, manipulators, manufacturing tools, etc., can solve the problems of contact, short extension length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

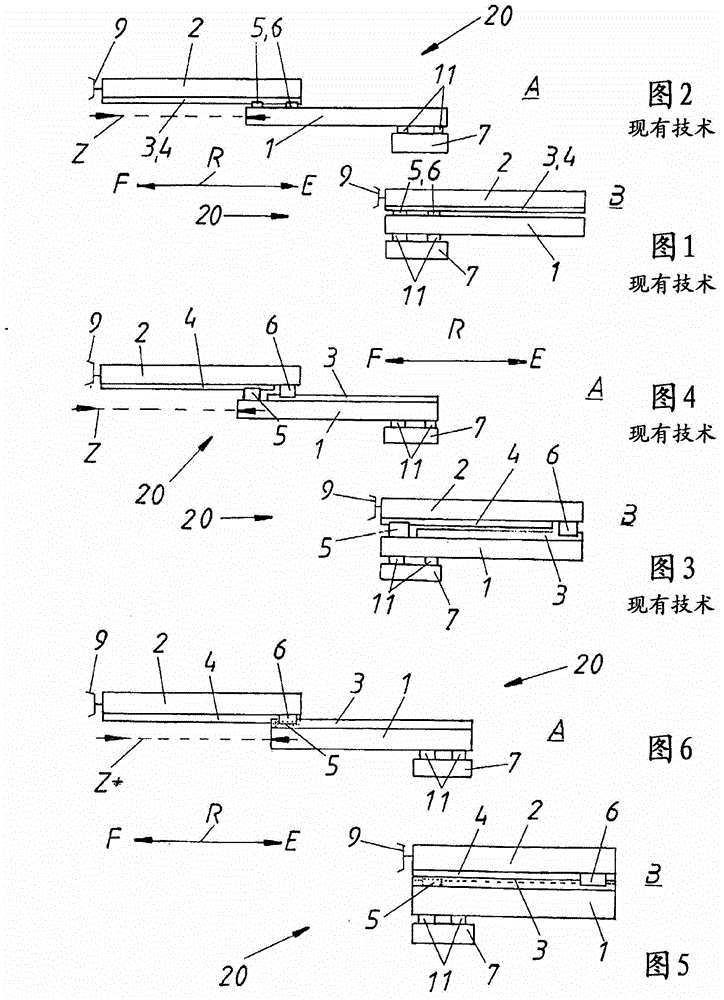

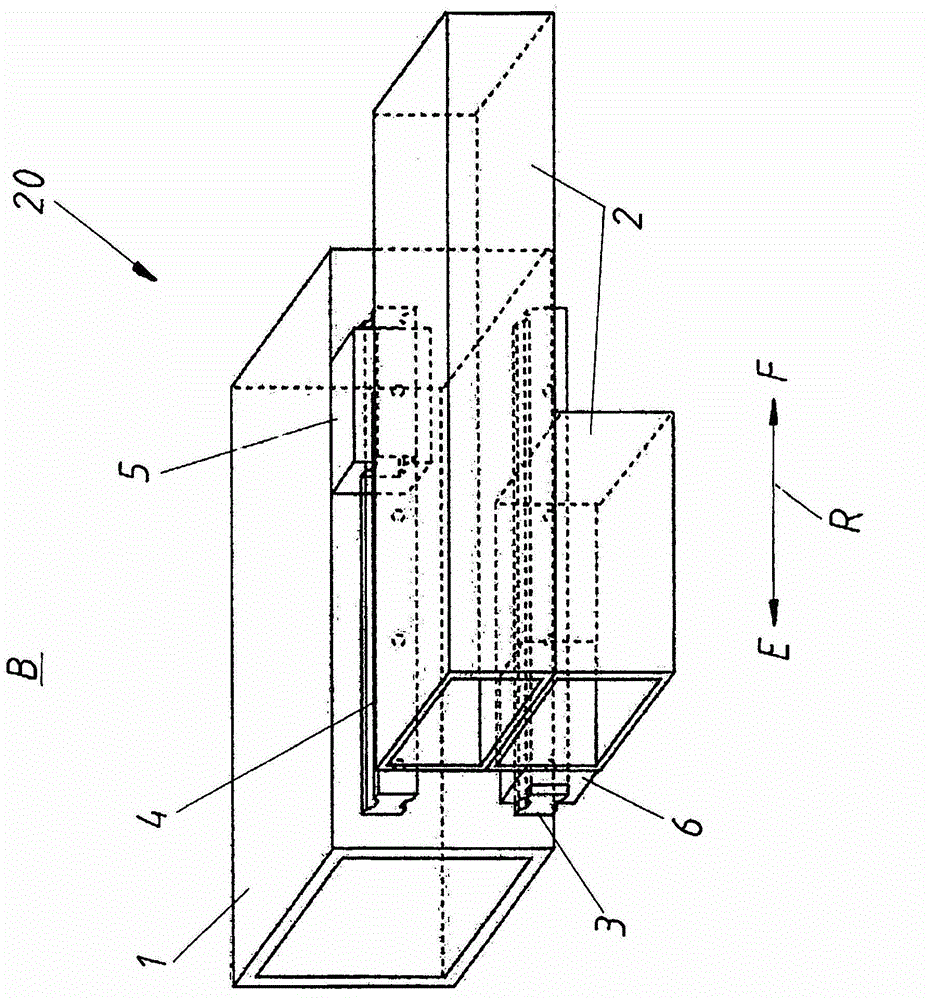

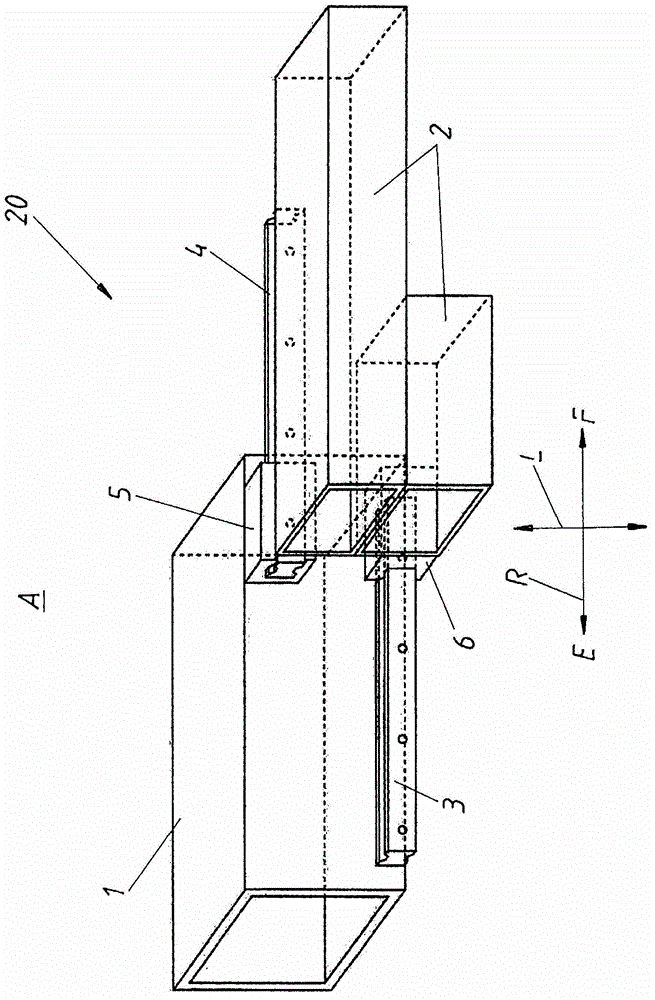

[0024] as already described Figures 1 to 4 On the one hand, the shortcomings existing in the prior art can be Figure 5 Shown to be overcome, the way is: in the shown retracted state B, the second guide block 6 that is arranged at the end of the second branch arm 2 pointing to the retraction direction E and shown in the previous part and The first guide rail 3 , likewise shown in the previous section, corresponds (ie matches) on the first partial arm 1 . In contrast, the guide block 5 arranged at the end of the first partial arm 1 pointing in the direction of extension F is shown in dashed lines in the rear part and is connected to the same in the rear part (in dashed lines) The second guide rail 4 of the second branch arm 2 is corresponding. Thus, especially compared to the figure 1 and 2 With the known prior art shown in , significantly better stability is obtained even in retracted state B.

[0025] exist Figure 6 A further advantage can be seen in , whereby a longe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com