Steel jacket

A technology of steel sleeves and sleeves, which is applied in the field of steel sleeves in heavy construction machinery, can solve the problems of short service life, waste, waste of lubricating oil, etc., and achieve the effect of reducing replacement costs, waste, and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

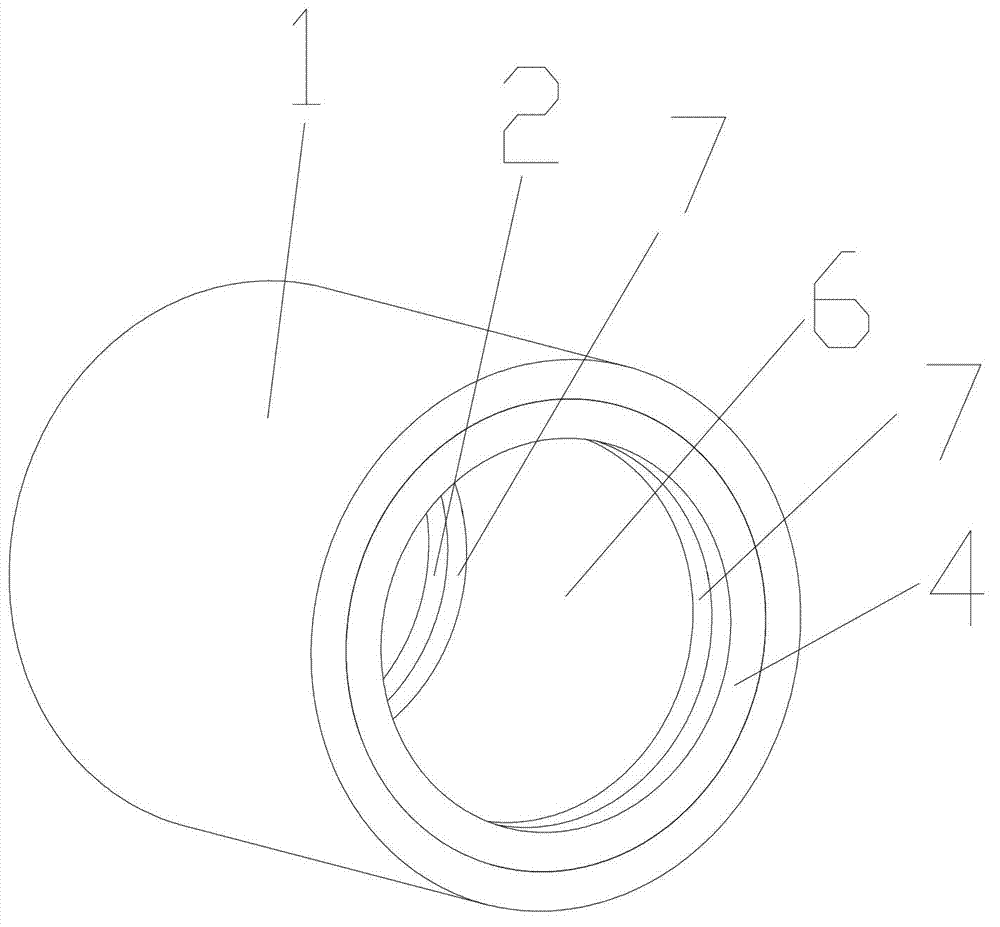

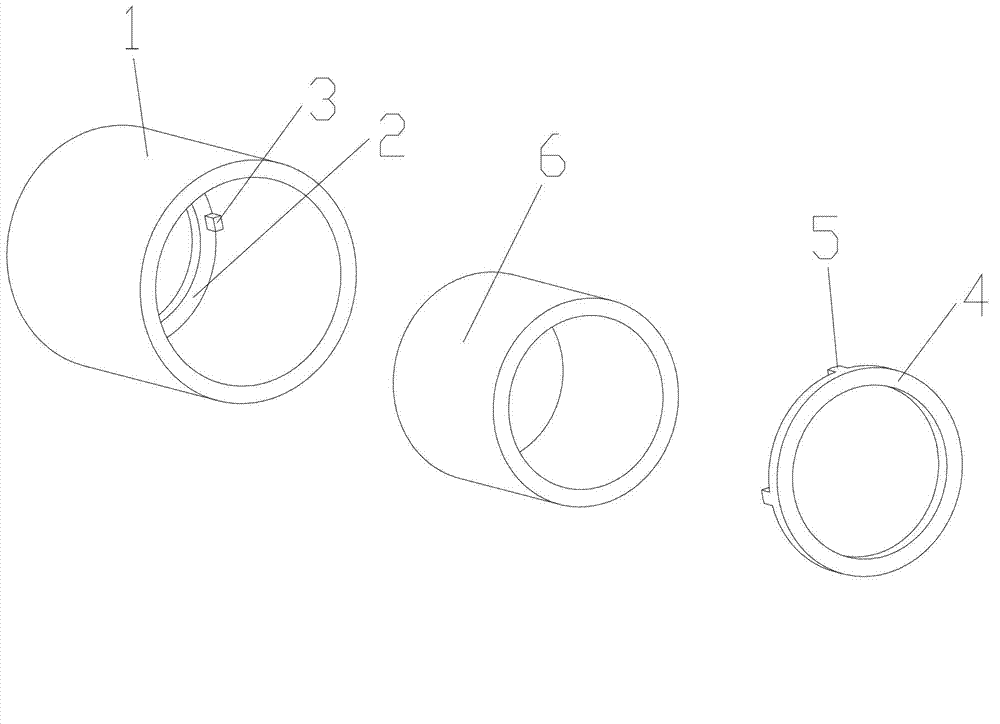

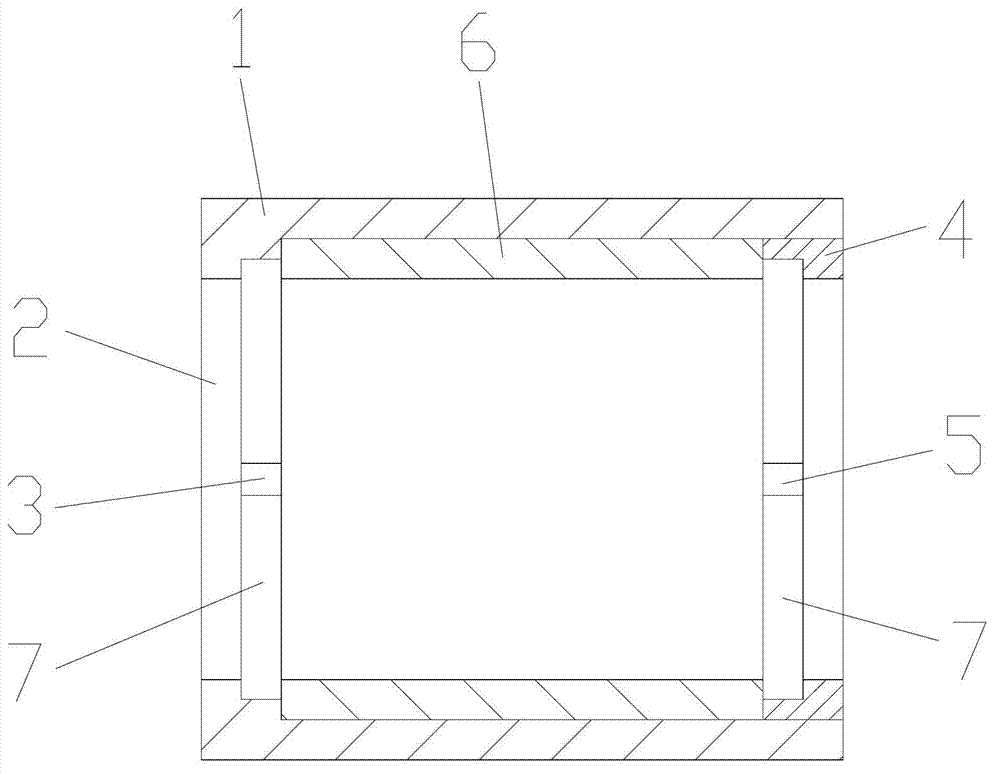

[0017] The present invention is described below in conjunction with accompanying drawing.

[0018] as attached Figure 1-3 The shown steel sleeve of the present invention includes a steel sleeve body 1, and a first retaining ring 2 is fixed at one end of the steel sleeve body 1; the inner surface of the first retaining ring 2 has an annular array with at least Two first bumps 3; the other end of the steel sleeve body 1 is equipped with a second stop ring 4; the inner surface of the second stop ring 4 has at least two second bumps 5 in an annular array; the The steel sleeve body 1 is also equipped with an inner sleeve 6; the inner sleeve 6 is located between the first bump 3 and the second bump 5; the outer diameter of the inner sleeve 6 is the same as the inner diameter of the steel sleeve body 1; The first stop ring 2 is the same size as the second stop ring 4; the inner diameter of the first stop ring 2 and the second stop ring 4 is the same as the inner diameter of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com