Automatic external-wall cleaning machine

An exterior wall cleaning machine, automatic technology, applied in the direction of cleaning machinery, cleaning carpets, cleaning floors, etc., can solve the problems of low work efficiency, high labor intensity, poor safety, etc., achieve high cleaning efficiency, reduce labor costs, avoid dangerous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

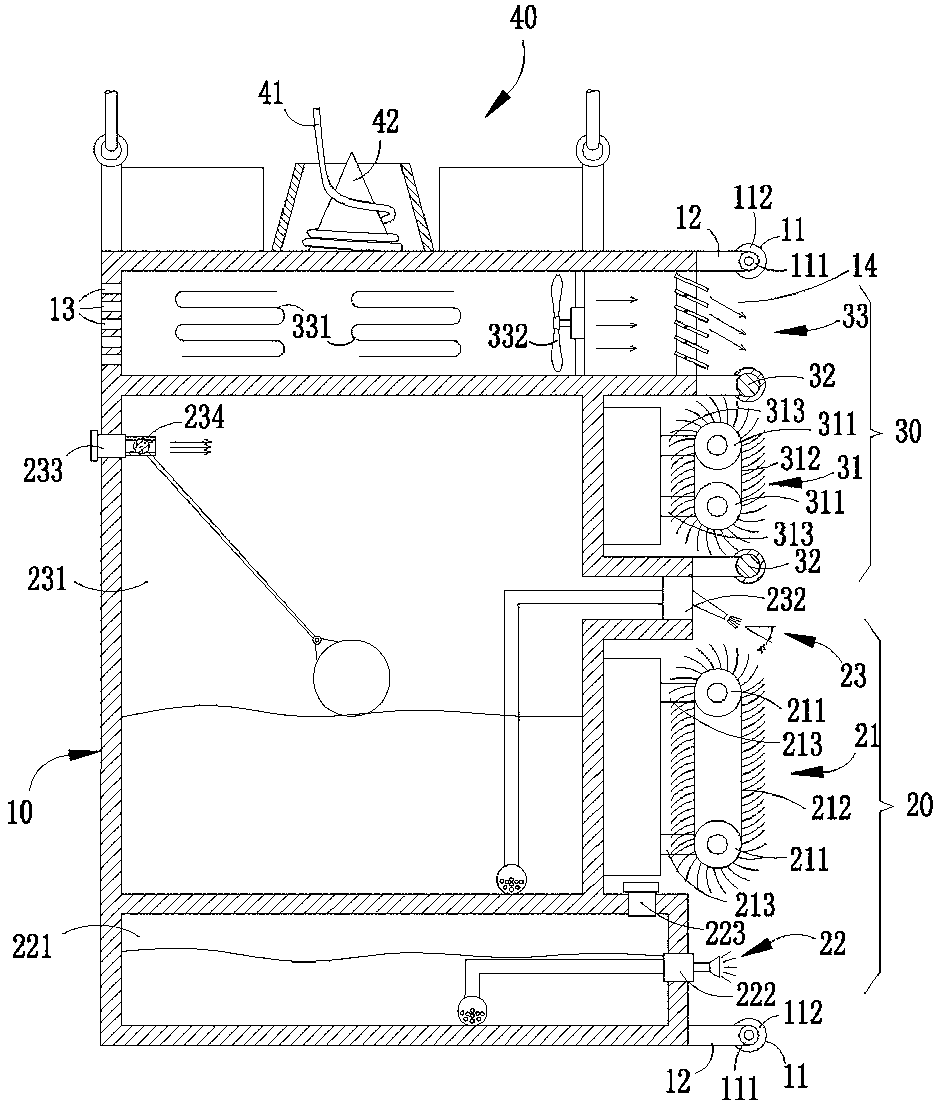

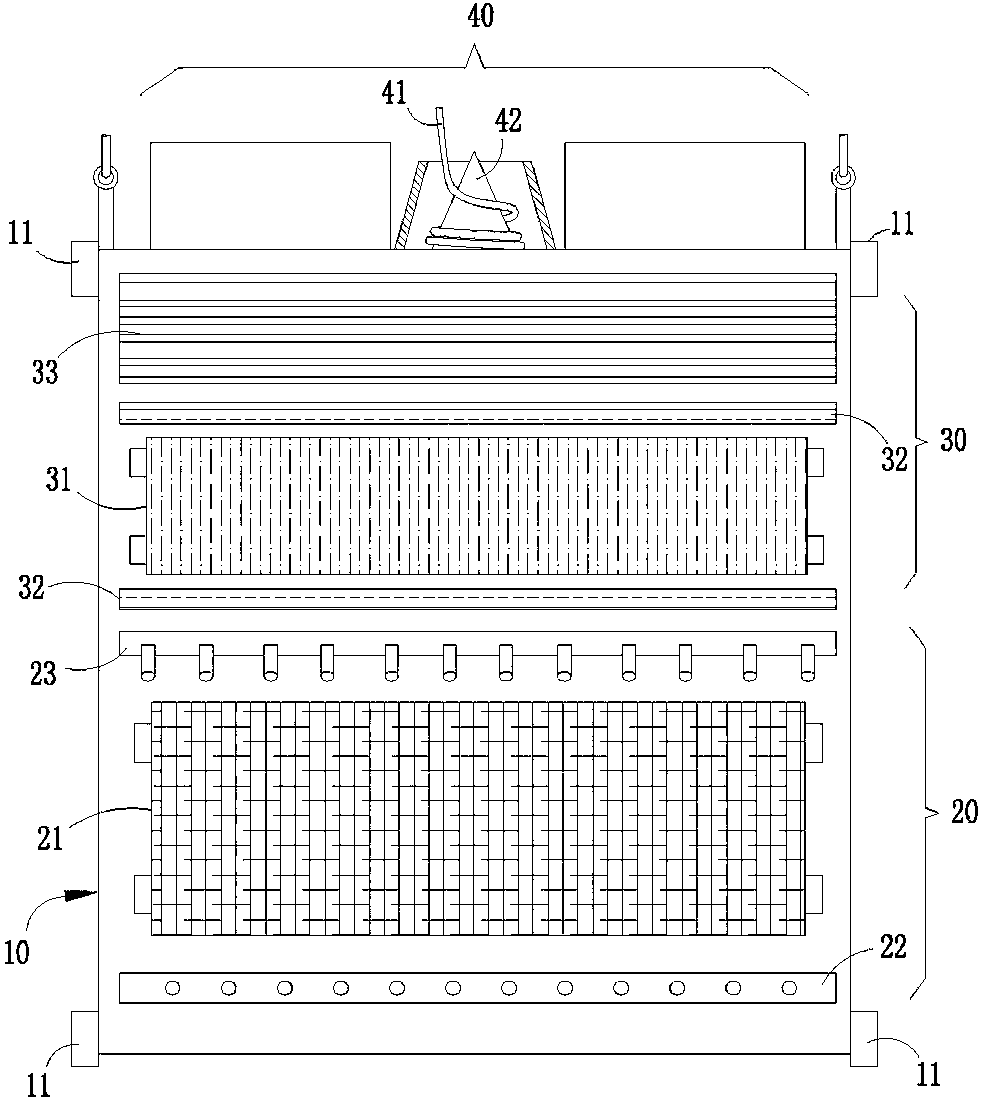

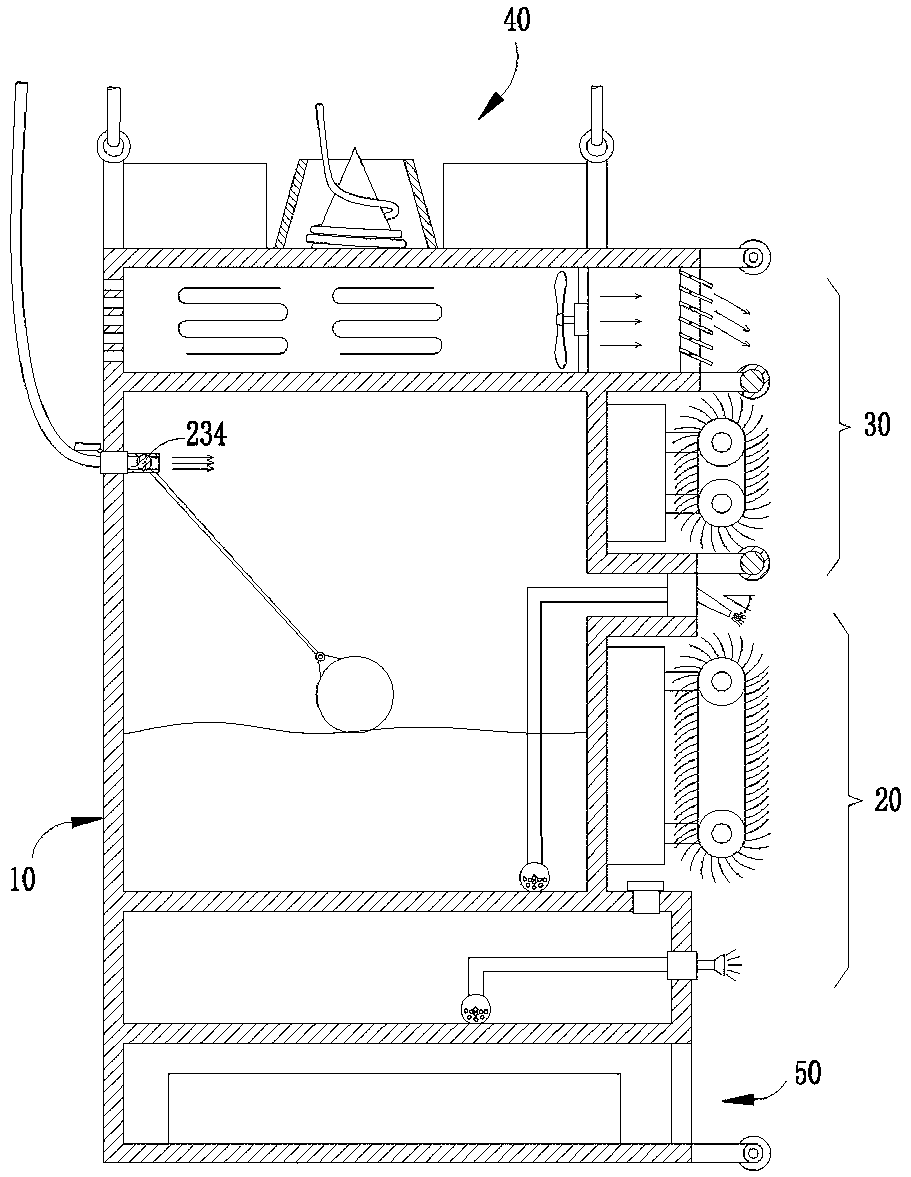

[0023] The following will be combined with Figures 1 to 4 And the preferred embodiment is a more detailed description of an automatic exterior wall cleaning machine proposed by the present invention.

[0024] like Figures 1 to 2As shown, the present invention provides an automatic exterior wall cleaning machine, which includes a frame 10, a cleaning unit 20 and a cleaning unit 30, and the cleaning unit 20 and the cleaning unit 30 are all arranged in the frame 10 , the cleaning unit 20 and the dry cleaning unit 30 are located on the same side of the frame 10, the dry cleaning unit 30 is arranged above the cleaning unit 20, and the frame 10 is a box A sling is connected to the top of the diagonal column of the box, and the other end of the sling is connected to a crane arranged on the top floor of the building.

[0025] The frame 10 is also provided with a control unit 40, the control unit 40 includes a general power distribution box and a wireless control box, through which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com