Gear involute electric spark repairing device

A technology of open wire and gear, which is applied in the field of large modulus pinion involute on-site repair device, can solve the problems that affect safety production, produce undercut, machine vibration and noise, etc., and achieve long service life and increased service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

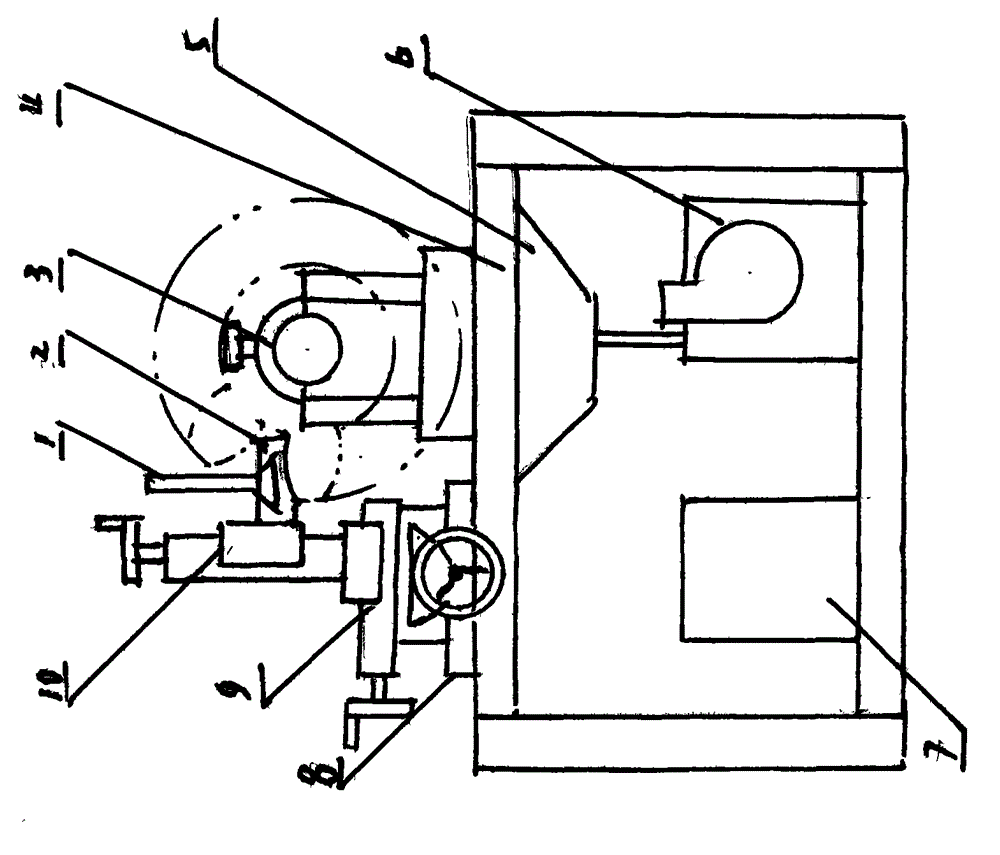

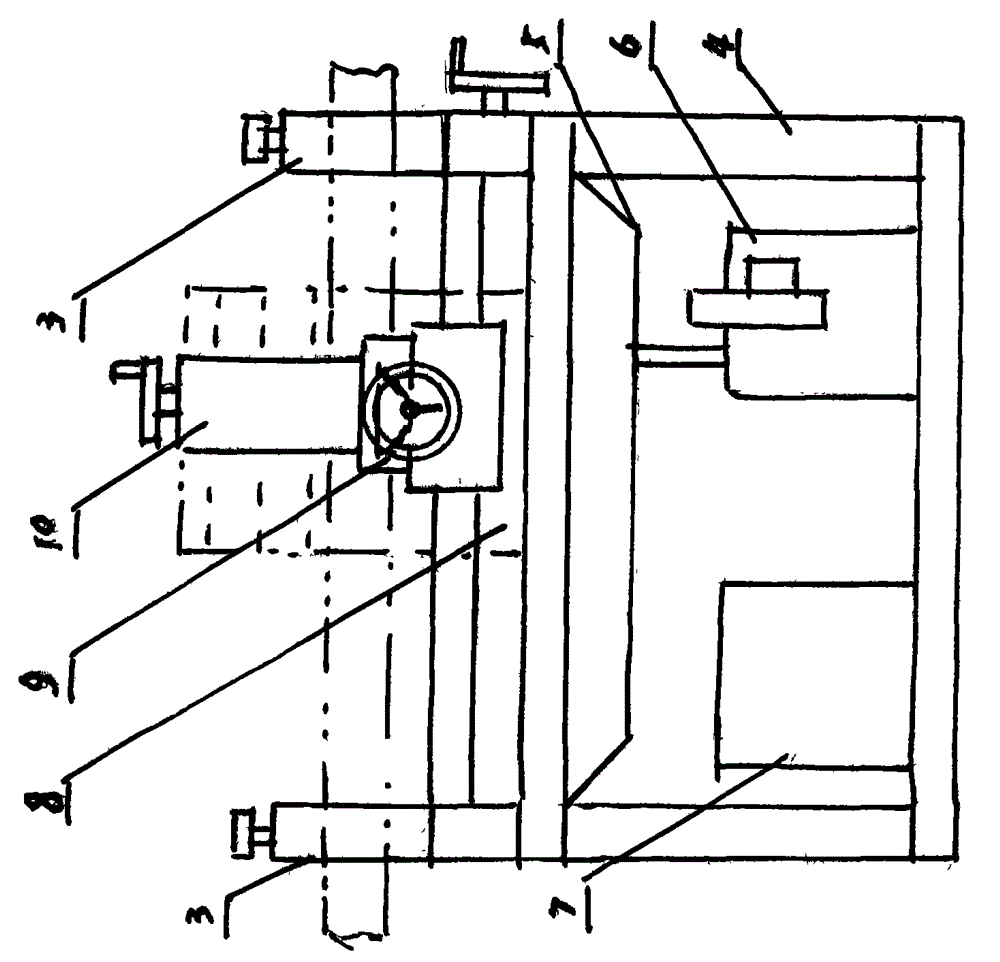

[0010] in figure 1 , 2 In the illustrated embodiment, two bearings 3 are provided on the frame 4 for fixing gear shafts. There is also a horizontal carriage 8. The carriage structure is the same as the carriage on a lathe, which can be made manually or electrically. Below the frame 4 are equipped with an oil return tank 5, a pulse power supply box 7, and an oil pump tank 6 The oil return tank 5 is connected to the oil pump tank 6. The vertical carriage 9 is fixed on the horizontal carriage 8, and the vertical carriage 10 is installed on the longitudinal carriage 9. The tool electrode 2 is made of a 2MM thick flexible conductive material in a strip shape. The discharge surface below is a gear involute shape. The insulating plate is movably connected, the insulating plate is fixed on the vertical carriage 10, and the tool electrode 2 is electrically connected to the pulse power box 7. The fuel injection pipe 1 is flat nozzle-shaped and installed on both sides of the tool electro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap