Pneumatic Nailer

A nail gun and pneumatic technology, applied in the field of automatic strapping equipment, can solve the problems of low work efficiency, unsafe, easy to hurt human hands, etc., and achieve the effects of improved automation, improved safety performance, and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

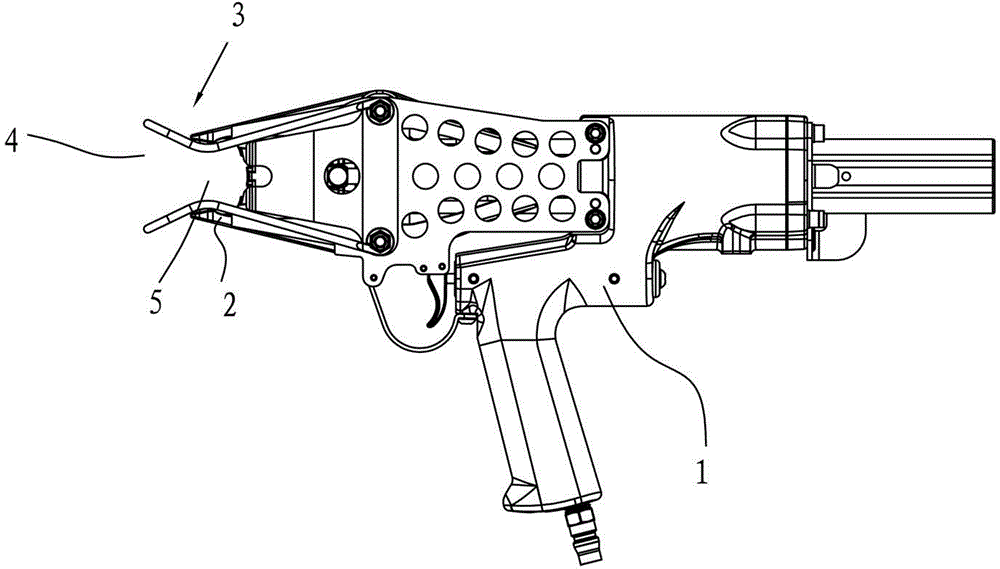

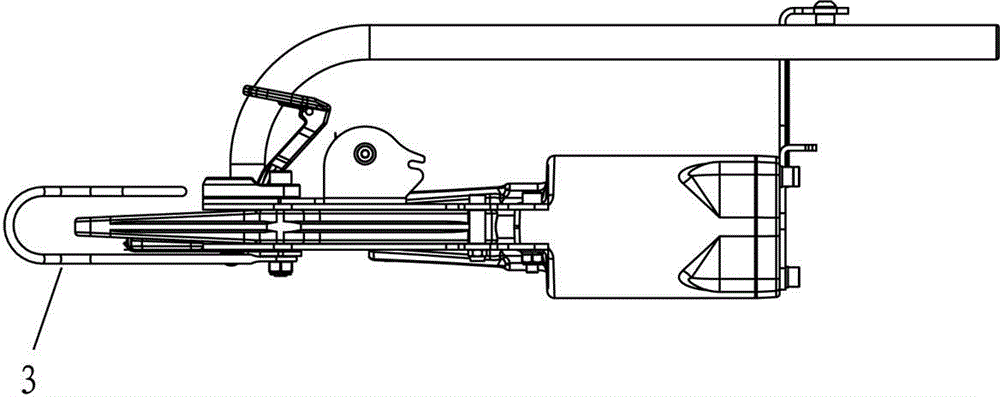

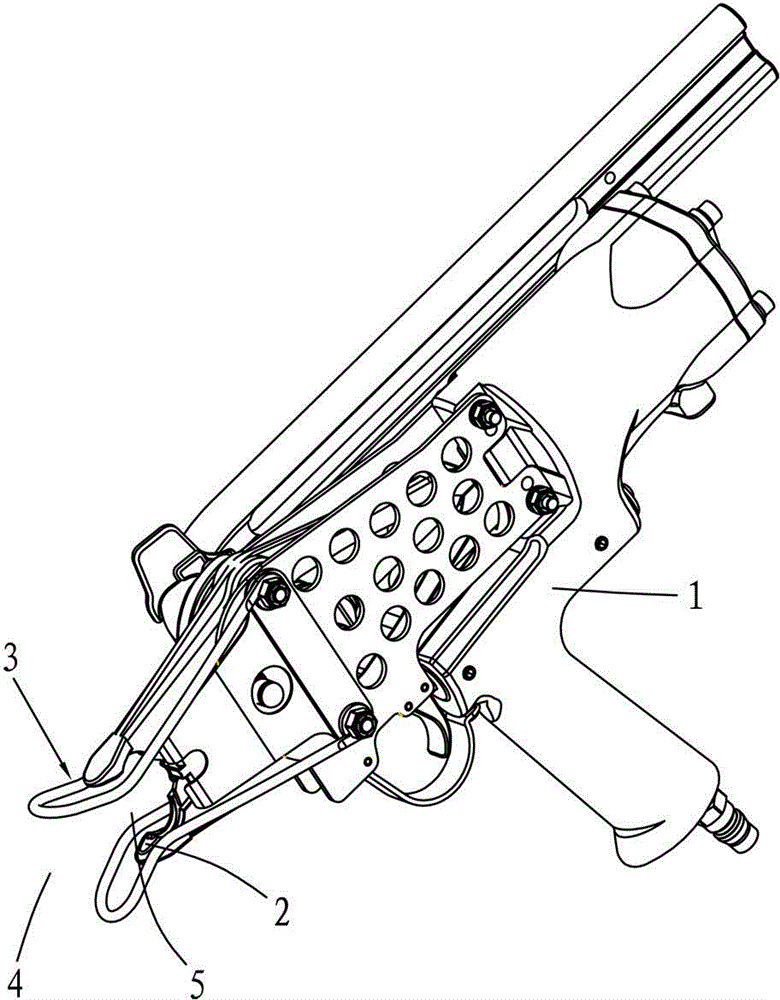

[0011] Example, combined with figure 1 and image 3 , a pneumatic nail gun, comprising a gun body 1, a nozzle 2, and a guide clip 3, the guide clip is formed by bending a metal wire, the tail end of the guide clip 3 is fixed on the gun body 1, so that the whole guide clip forms a hanging Wall structure, the head end of the guide clip 3 extends along the axial direction of the gun body 1 to the end of the gun mouth 2, and forms an outward expansion opening 4 in front of the gun mouth 2, and the guide clip 3 at the gun mouth 2 forms a clip The tight mouth 5, the distance between the clamping mouth 5 and the expansion mouth 4 expands outwards, and the clamping distance of the clamping mouth 5 is less than or equal to the maximum opening distance of the gun nozzle 2 . Compress the object through the expansion port of the guide clip and introduce it into the clamping port. Since the clearance of the clamping port is less than or equal to the maximum opening of the gun nozzle 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com