Numerical control full-automatic impregnated glove production line

A production line, fully automatic technology, applied in the direction of spraying device, liquid spraying device, paint spraying room, etc., can solve the problems of inconvenient separation work, inconvenient to improve gas treatment effect, inconvenient for spraying and dipping work, etc., to improve purification effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

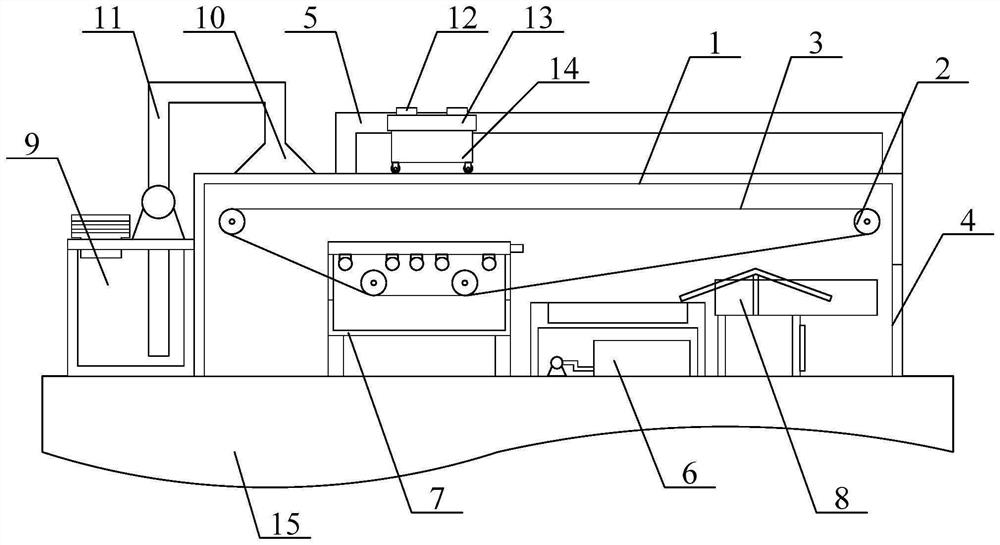

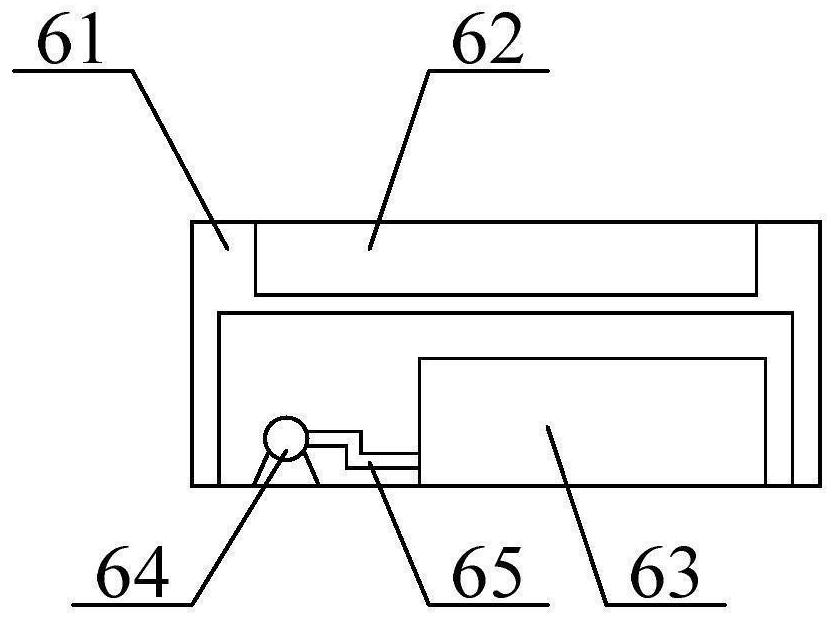

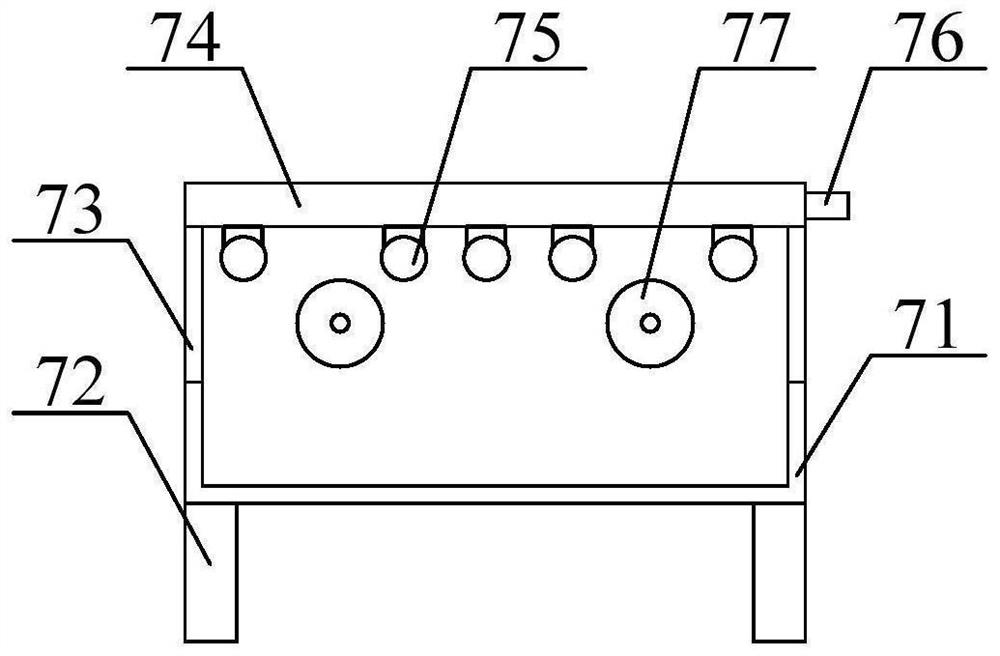

[0025] as attached figure 1 And attached figure 2 As shown, a CNC automatic dipped glove production line according to the present invention includes a dipped shell 1, a first guide roller 2, a closed chain 3, a first inlet and outlet hole 4, and an inverted U-shaped bracket 5, which can be sorted and transported Filling seat structure 6, sprayable dipping box structure 7, adsorption and separation guide frame structure 8, sealable negative pressure treatment box structure 9, suction hood 10, guide pipe 11, sliding pipe 12, first support plate 13. Sliding control box mechanism 14 and fixed base 15, first guide rollers 2 are respectively provided on the upper parts of the left and right sides of the inside of the dipped shell 1; the outer wall of the first guide roller 2 is provided with closed chains 3; the lower right side of the dipped shell 1 is provided with a first acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com