Plug-in spare tire mechanism

A spare tire carrier and tire cover technology, applied in the field of auto parts, can solve the problems of hindering luggage access, increasing the complexity of operations, and difficult to integrate the appearance into the overall shape, etc., to achieve the effect of convenient daily use and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

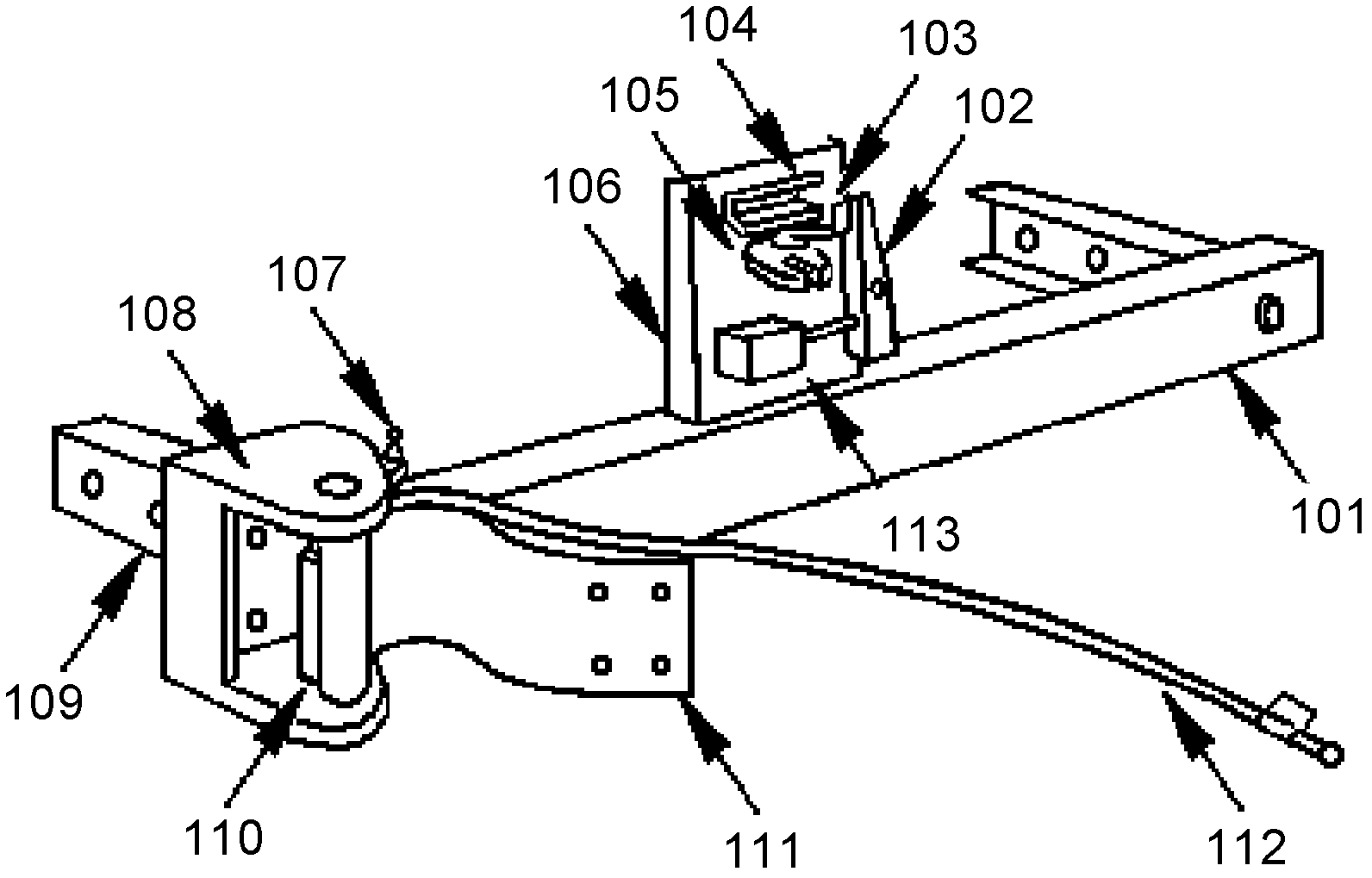

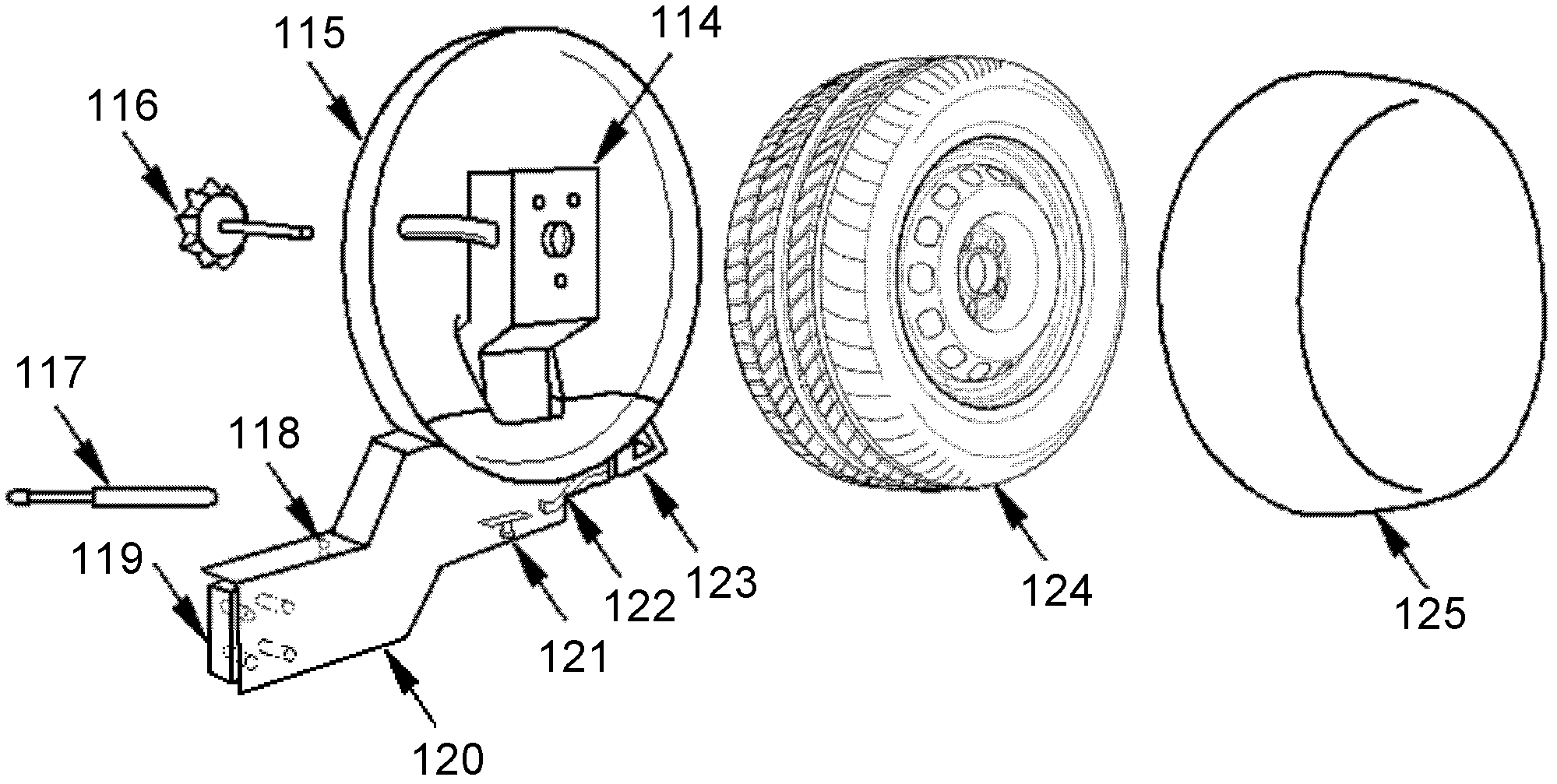

[0034] refer to figure 1 and figure 2 As shown, the present invention discloses an external spare tire mechanism, comprising:

[0035] The crossbeam assembly 101, the two ends of the crossbeam assembly 101 are connected with the guide arm 109, and the guide arm 109 is embedded in the rear longitudinal beam of the vehicle body. In one embodiment, the guide arm 109 is welded on the beam assembly 101, and the guide arm 109 is connected to the rear longitudinal beam of the vehicle body by bolts to ensure reliable connection strength.

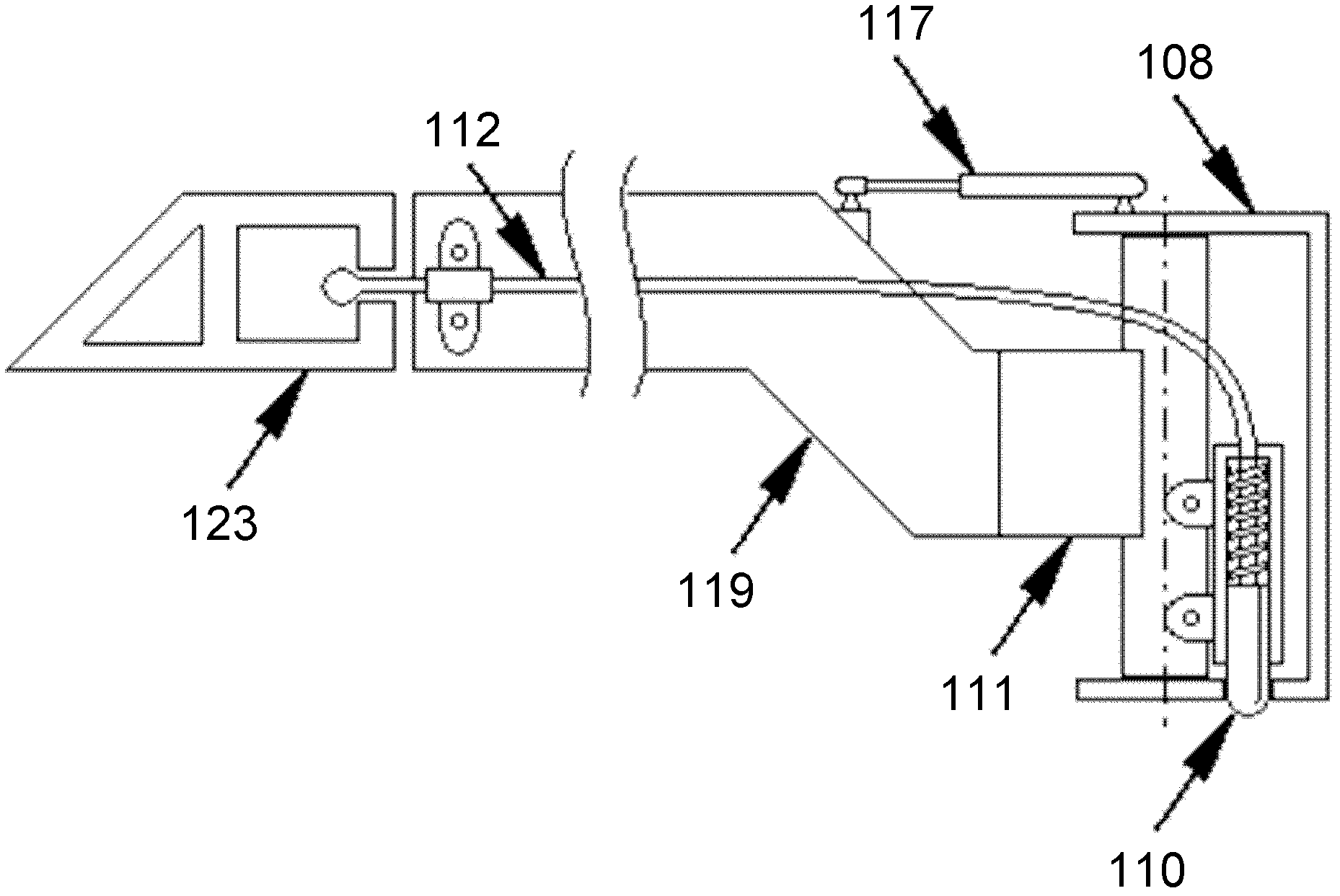

[0036] The rotating shaft support 108 is located at one end of the beam assembly 101 . There is a first gas spring seat 107 on the rotating shaft support 108 . There is also a locking hole on the rotating shaft support 108, which can make the sliding post mechanism 110 slide into the locking hole and lock (refer to image 3 shown).

[0037] The locking module bracket 106 is fixed on the middle part of the beam assembly 101 , and the locking mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com