Detection method and detection device for food safety by use of supersonic wave

A food safety and detection method technology, applied in the detection field, can solve the problems of lack of detection management announcement system, food safety situation worsening, food safety distrust, etc., to achieve portable and cheap devices, reduce costs and eliminate inconvenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited by the embodiments.

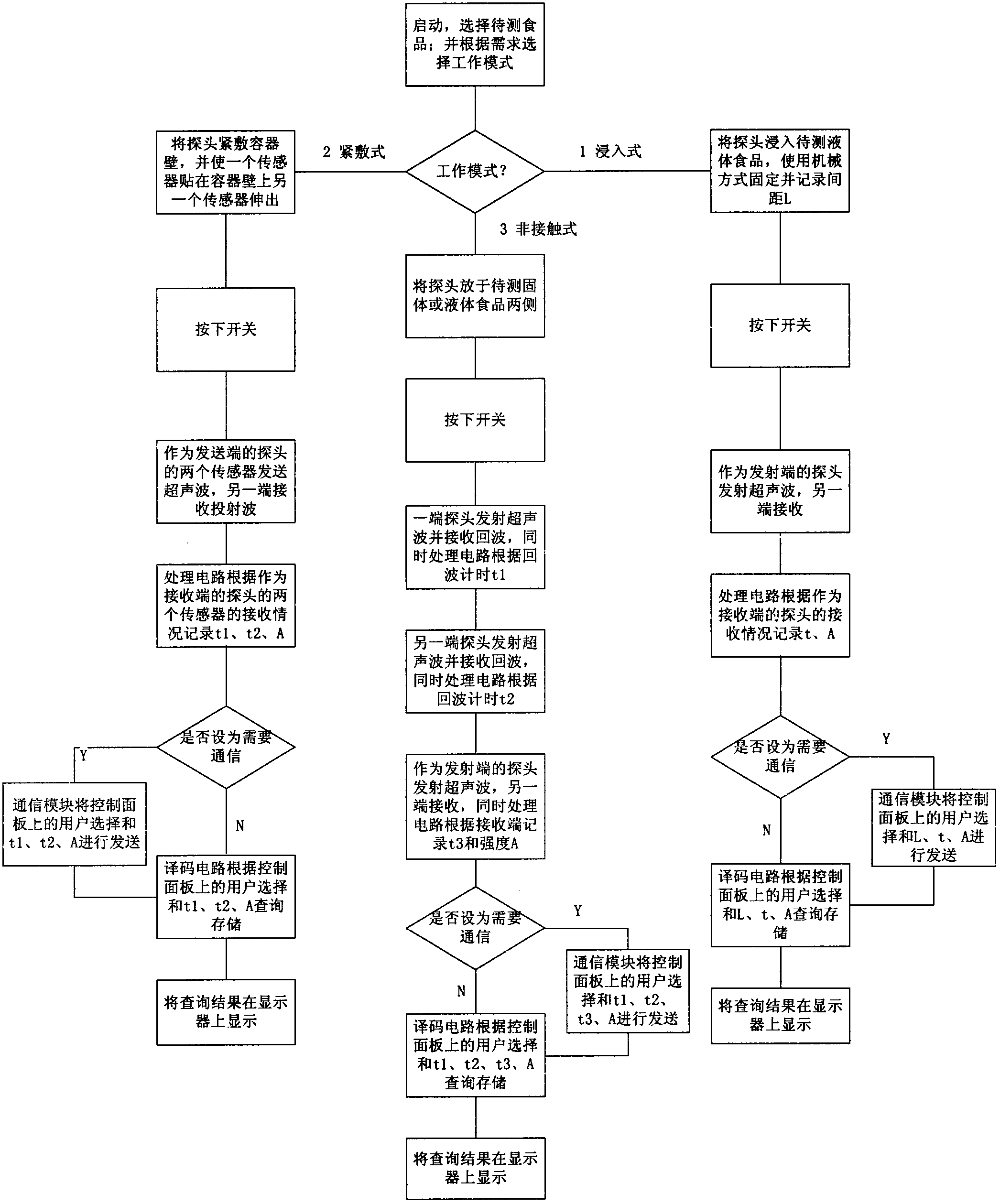

[0023] An ultrasonic food safety detection method designed by the present invention utilizes ultrasonic reflection method and / or ultrasonic transmission method to detect food and collects data, uses data fitting or regression analysis to establish a relationship model, and then obtains food quality through table lookup, specifically ultrasonic food The security detection method is:

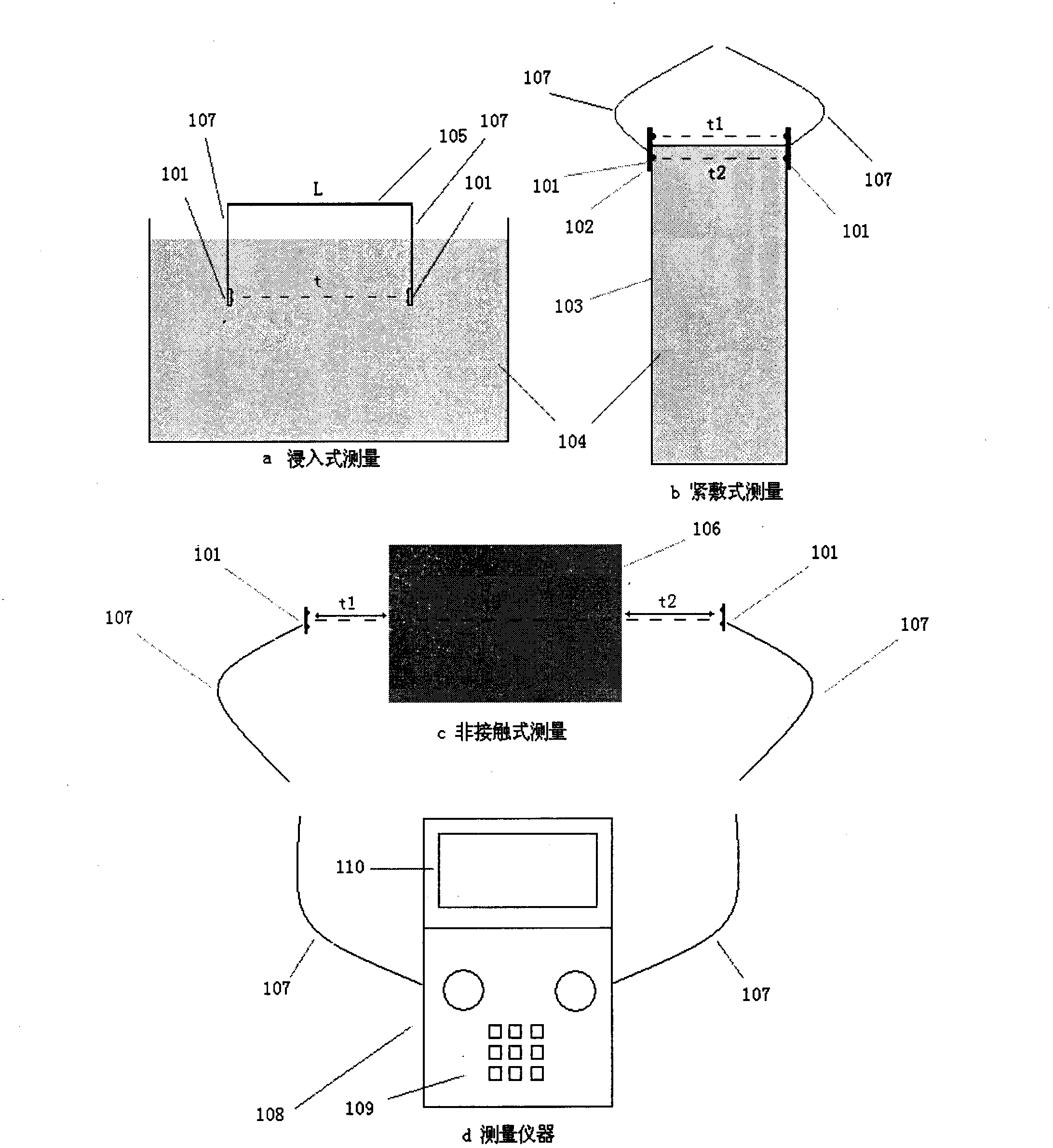

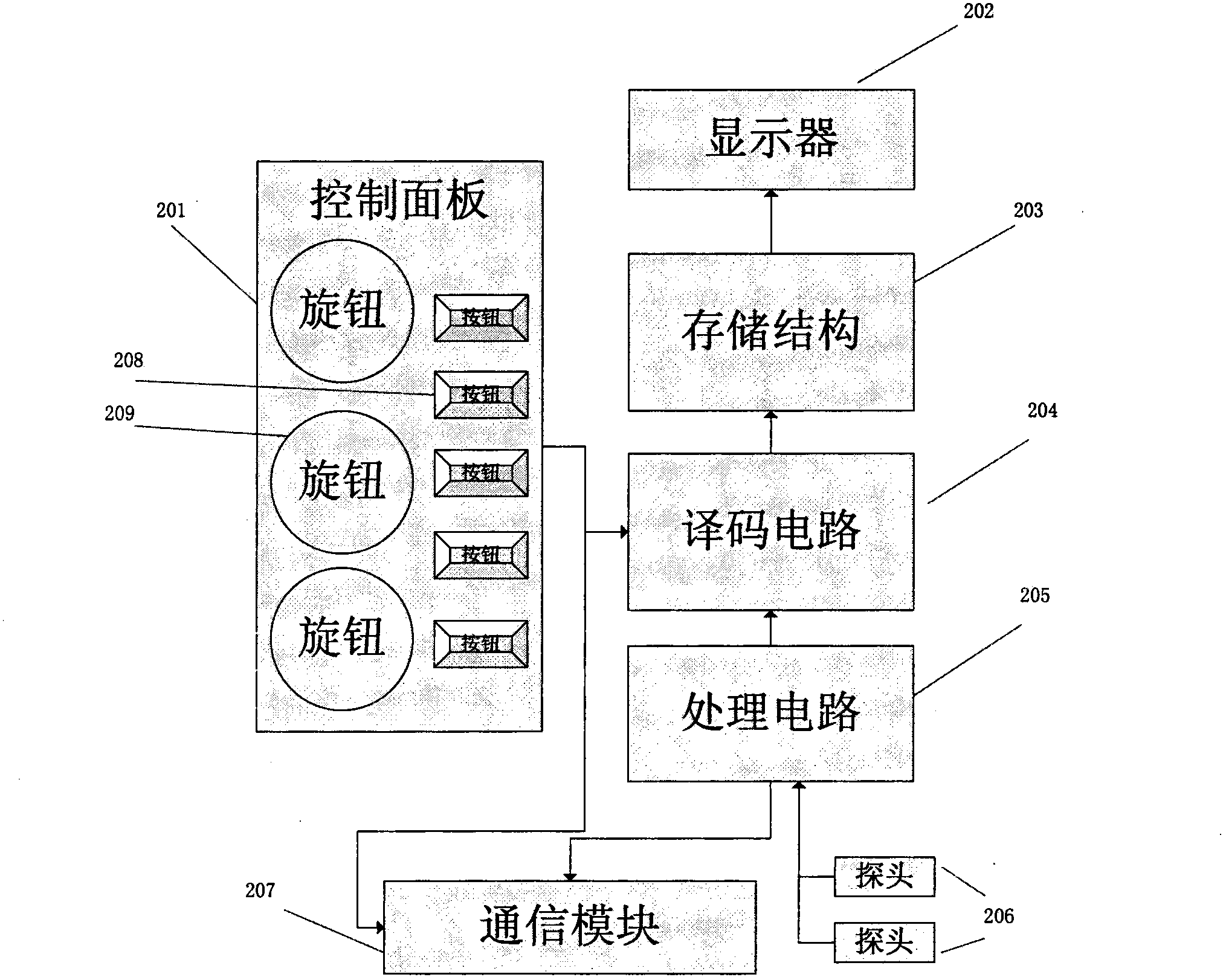

[0024] figure 1 , the method used in an embodiment of the ultrasonic food safety detection method. 101 is a measuring probe, which is equipped with two ultrasonic transducers 102 integrated with transceivers, which can be compared during tight-fitting measurement to avoid distance measurement. The method is to allow one sensor of the two probes to be attached to the container wall 103 and the other to protrude fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com