Conveying device

A technology of conveying device and conveyor belt, which is applied in the directions of transportation and packaging, packaging, and packaging protection. It can solve the problems of accumulation in the packing work section and the speed of manual packing cannot keep up, so as to reduce packing time and improve packing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

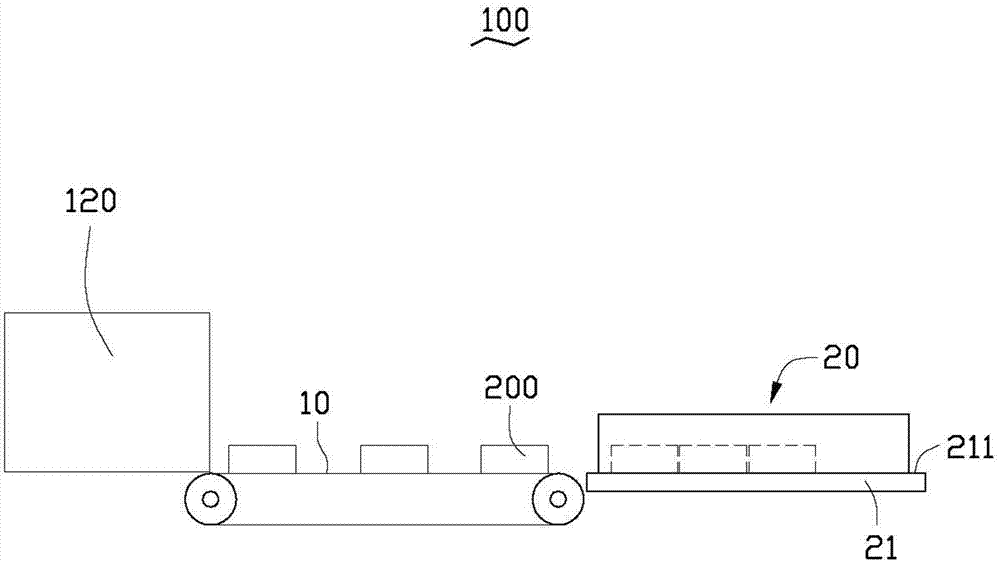

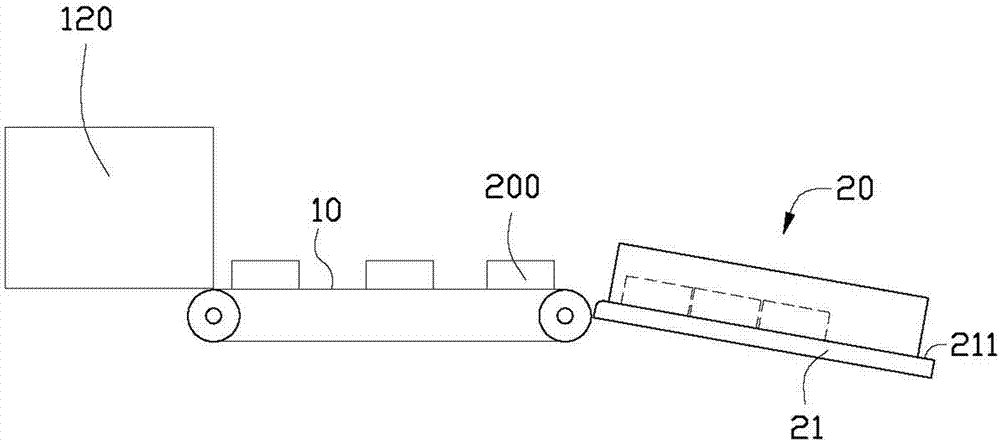

[0026] See figure 1 , The conveying device 100 provided by the embodiment of the present invention is used for conveying the product 200 to be boxed, which is packaged in a single package in the packaging section 120, to the boxing section for boxing. The conveying device 100 includes a conveyor belt 10 and deceleration cleaning Unit 20.

[0027] In this embodiment, the conveyor belt 10 is used to transport the product to be boxed 200 to the deceleration cleaning unit 20, and the product to be boxed 200 is a single pack of paper towels.

[0028] The deceleration cleaning unit 20 is used to reduce the forward speed of the product 200 to be boxed conveyed by the conveyor belt 10, and to clean the product 200 to be boxed at the same time.

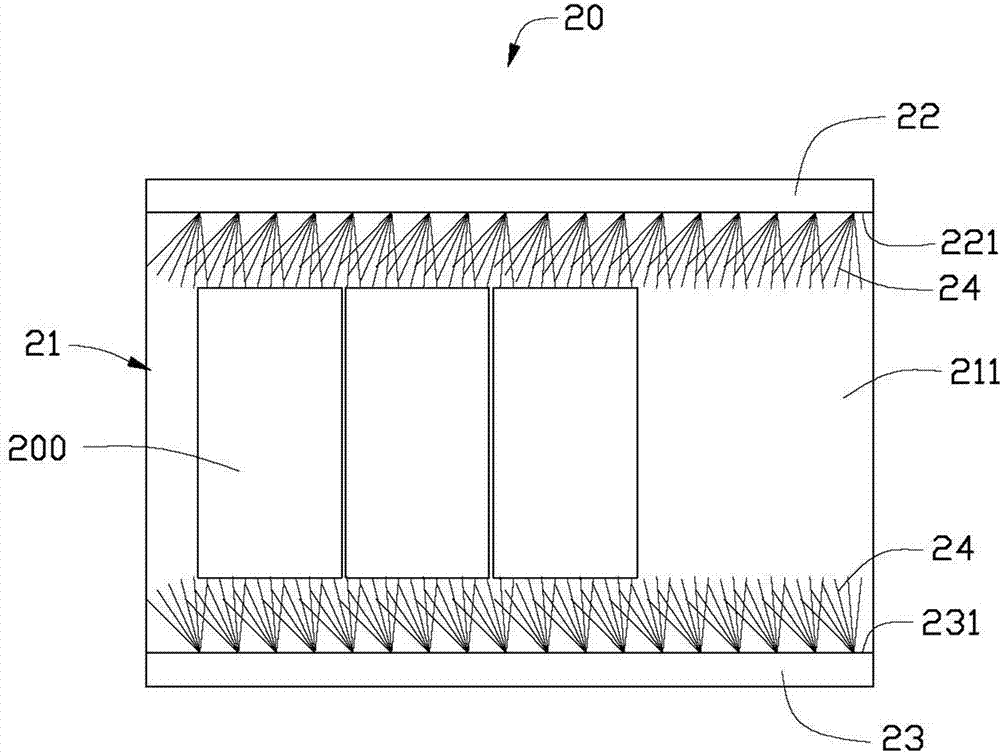

[0029] Such as figure 2 As shown, the deceleration cleaning unit 20 includes a carrying plate 21 and a first brush plate 22 and a second brush plate 23 arranged on opposite sides of the carrying plate 21 along the extending direction of the carrying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com