Device and method for paving floor boards of container

A container and floor technology is applied in the field of container floor and container floor paving equipment, which can solve the problems of large equipment investment and complex structure, and achieve the effects of simple equipment, simple paving process and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

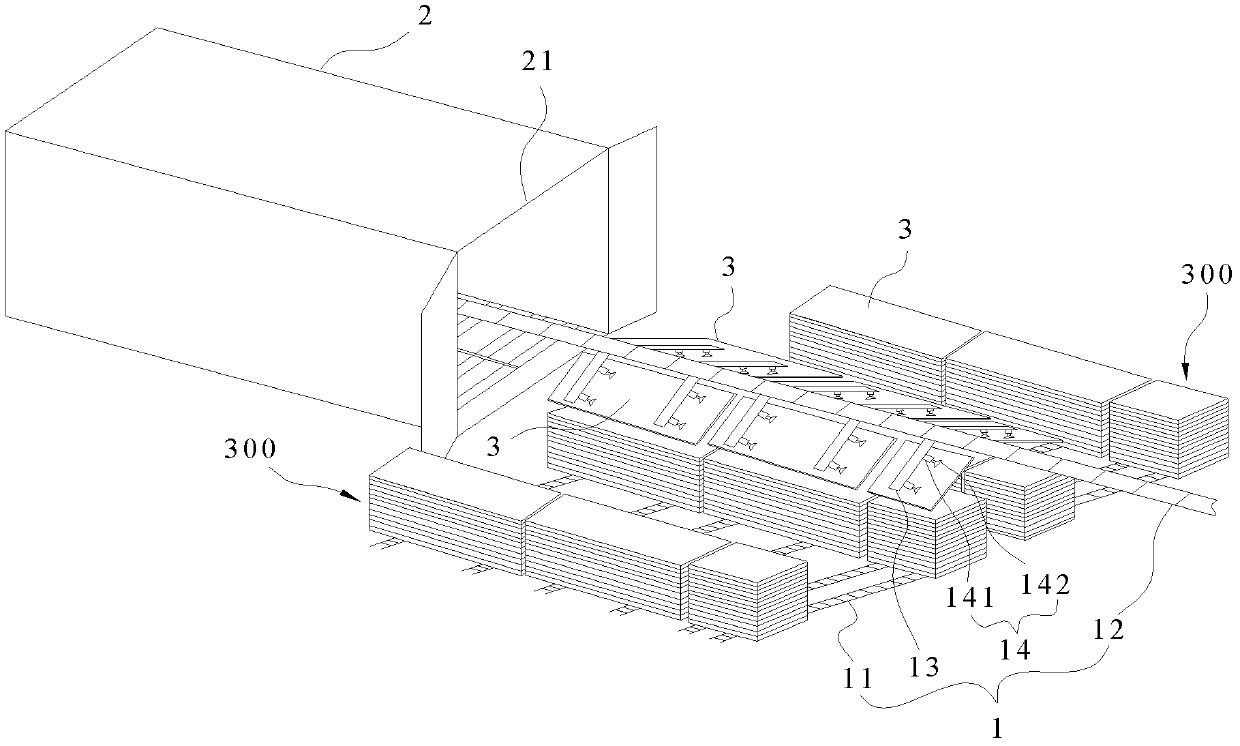

[0029] see figure 1 As shown, the container floor paving equipment 1 of the present invention is arranged on the container floor paving station to pave the container floor 3 on the container 2 delivered to the container floor paving station, and the plurality of container floors 3 are stacked neatly to form The container floor stack 300 , the container floor paving equipment 1 includes an external transmission mechanism 11 , a guide mechanism 12 , multiple translation and steering mechanisms 13 and multiple lifting and grabbing mechanisms 14 .

[0030] The external transfer mechanism 11 is horizontally arranged outside the door end 21 of the container 2 at the container floor paving station and can drive the container floor pile 300 on it to the container door en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com