A splicing method for modular floor heating

A modular, floor heating technology, applied in heating methods, hand-held appliances, hot water central heating systems, etc., can solve the problems affecting the promotion and application of wet heating and dry heating, unsatisfactory heat conduction performance, and high heating energy consumption. The effect of reducing the paving workload, simplifying the paving process and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is further described:

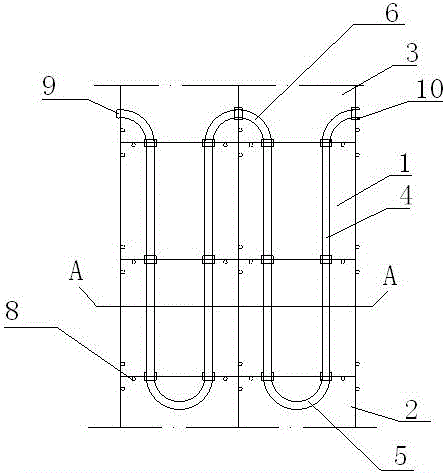

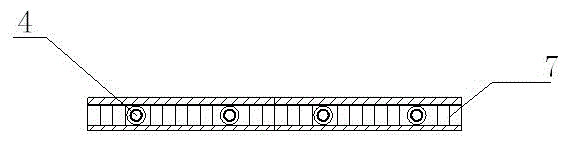

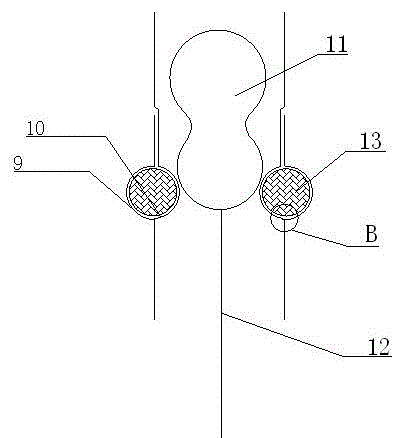

[0017] The modular floor heating of the present invention includes: a straight pipe module 1 , a bending module 2 and an arc connection module 3 . Two parallel straight pipes 4 for passing water are arranged between the upper and lower parallel plates of the straight pipe module, and a semi-circular arc pipe 5 for water passage is arranged between the upper and lower parallel plates of the bending module, and the upper and lower parallel pipes 5 of the arc connecting module A 1 / 4 arc-shaped pipe 6 for passing water is arranged between the plates. Between the upper and lower parallel plates of each module, there is a reinforcing rib 7 to increase the strength of the module, and each module is provided with 2-3 wedge-shaped snap-in buckles 8 composed of wedge-shaped protrusions and wedge-shaped notches that are tightly engaged with each other at the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com