Double-inner-core buckling-preventive support structure

An anti-buckling bracing and core technology, which can be used in earthquake-proofing, building components, etc., can solve the problems of limiting the popularization and application of anti-buckling bracing, the influence of the fatigue performance of the core, and the difficult design of the bracing core, so as to achieve broad market promotion and application prospects. , The structure is simple, the effect of improving the seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

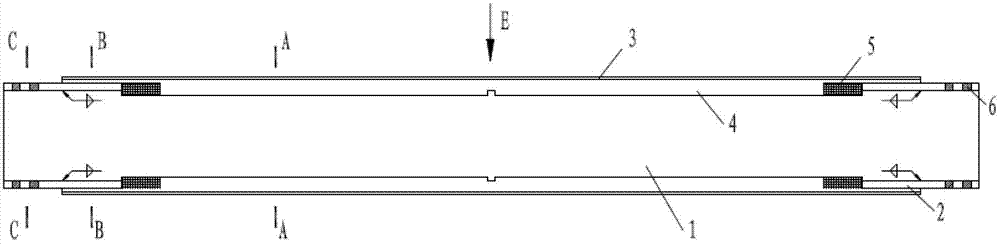

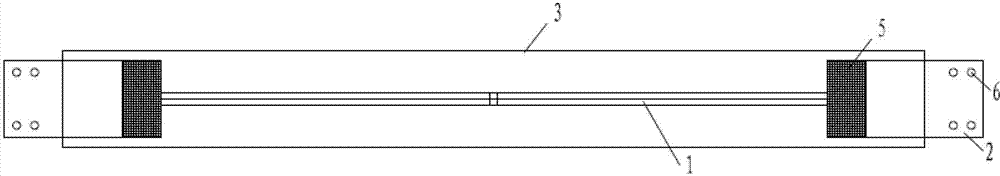

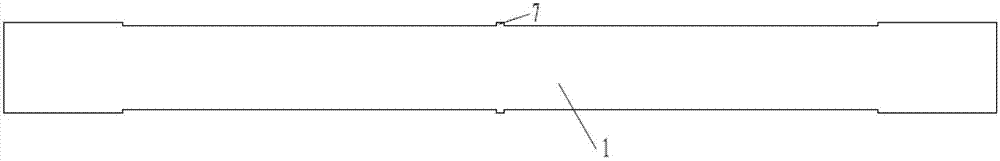

[0028] Such as figure 1 , figure 2 As shown, it includes a straight steel plate inner core 1, a flange steel plate 2, an outsourcing steel pipe 3 and concrete 4. The core energy-dissipating element is two flat-shaped steel plates 1 arranged side by side, and each flat-shaped steel plate 1 is in the shape of a mallet with wide ends and a thin middle; Formed by welding, the cross-section of the flat steel plate 1 and the flange steel plate 2 forms an "I" shape, the purpose is to weaken the influence of the residual stress at the welding point on the performance of the energy dissipation section of the core; when the flange steel plate 2 and the flat steel plate 1 are connected One side of the front end is filled with a certain length of porous foam material 5, so that the space reserved for the inner core to move axially when pouring concrete. Connecting structures, in this case through-holes 6 , can be provided on the flange steel plate 2 for connection to the structure.

...

Embodiment 2

[0034] see Figure 8 , the difference from Embodiment 1 is that two double-core anti-buckling support structures 10 are arranged in one span. At this time, an embedded panel 13 needs to be arranged in the middle of the frame beam 11, and if necessary, stiffeners need to be added on the embedded panel 13 to ensure connection strength and rigidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com