Scramjet engine flame stabilizing device with front edge air cleft structure

A scramjet and flame stabilization technology, applied in ramjet engines, mechanical equipment, etc., can solve the problems of poor air mixing effect, mainstream air mixing, and less material and energy exchange, and achieve enhanced mixing effect and flow loss Small, small effect of flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

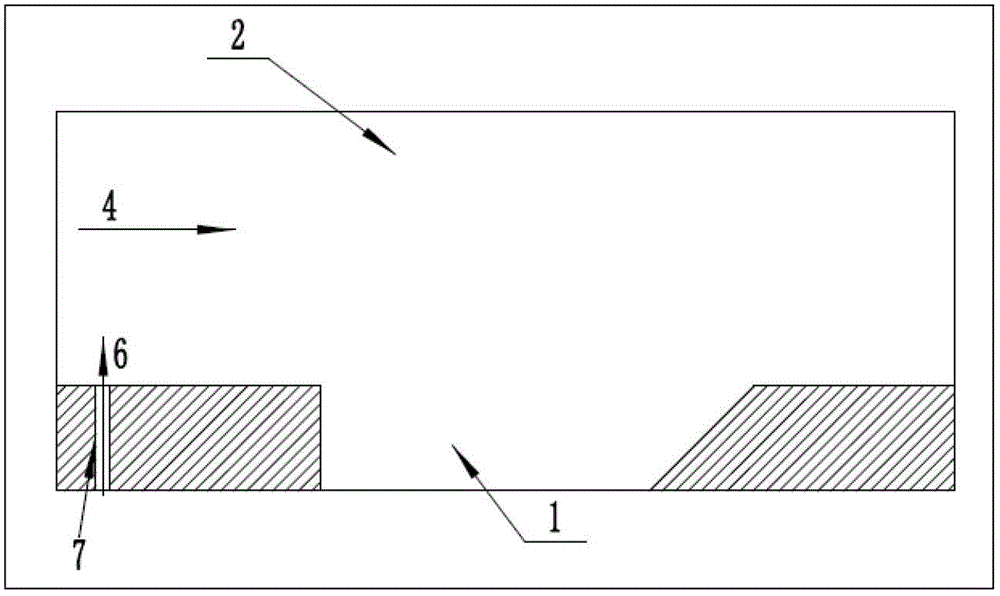

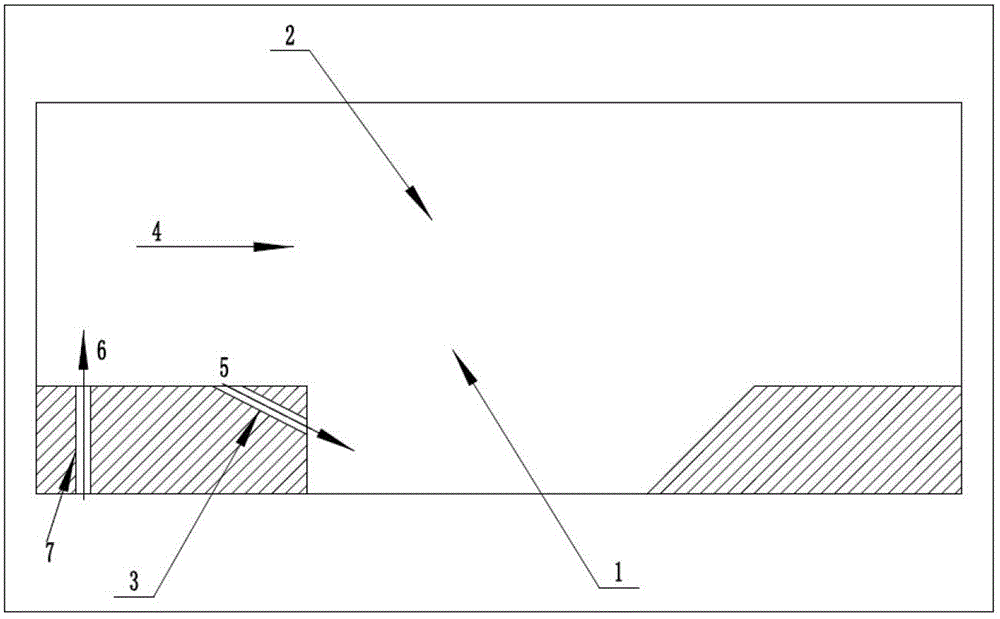

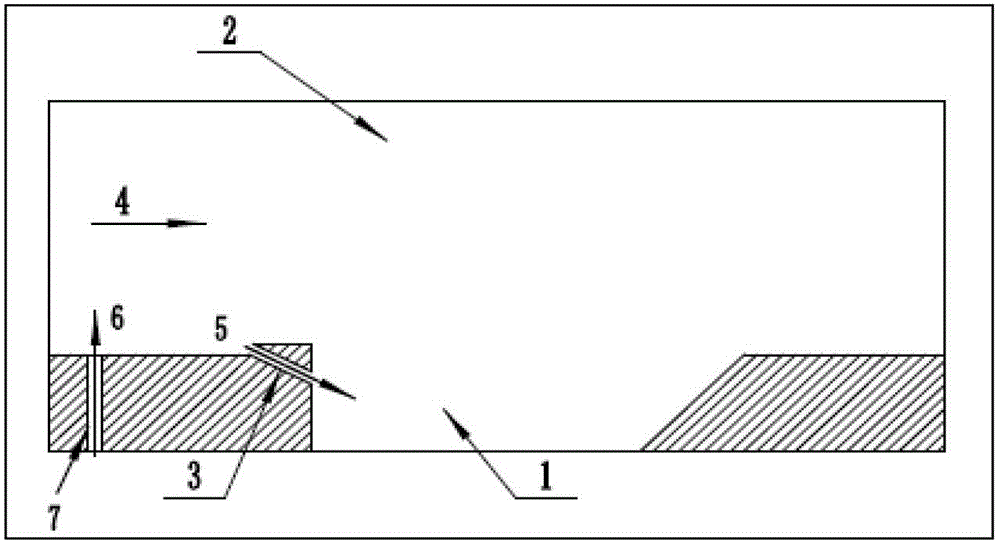

[0020] The present invention firstly provides an embodiment without a front-end fuel nozzle. Since the fuel supply varies under different pressure conditions, the embodiment of the present invention is carried out under two pressure conditions, namely 0.81MPa and 1.21MPa. Wherein, the structures of the main flow channel 2 of the super-combustion combustion chamber and the super-combustion groove flame stabilizer 1 are the same as those of the traditional groove flame stabilizer, and the groove leading edge gas is introduced into the front end of the super-combustion groove flame stabilizer 1 of the H0 and H1 structures. Slit 3, the airflow 4 of the main channel of the super-combustion combustion chamber enters the super-combustion groove flame stabilizer 1 through the air gap 3 at the front edge of the groove, so as to increase the mass exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com