Automatic calibrating apparatus and method based on CCP (CAN (Controller Area Network) Calibration Protocol) protocol

An automatic calibration and protocol technology, applied in the direction of electrical testing/monitoring, etc., can solve problems such as time-consuming and laborious, not suitable for mass production of controllers, and constraints on calibration results, and achieve high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

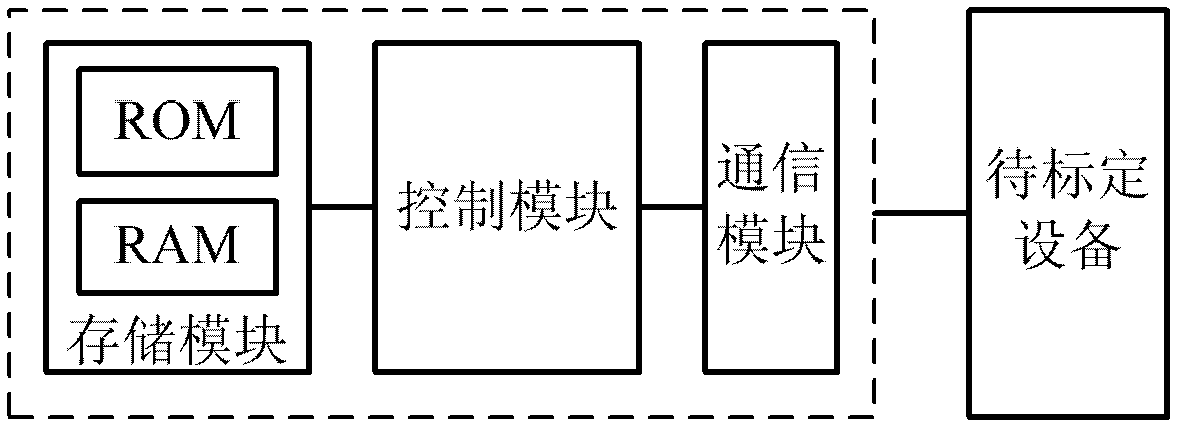

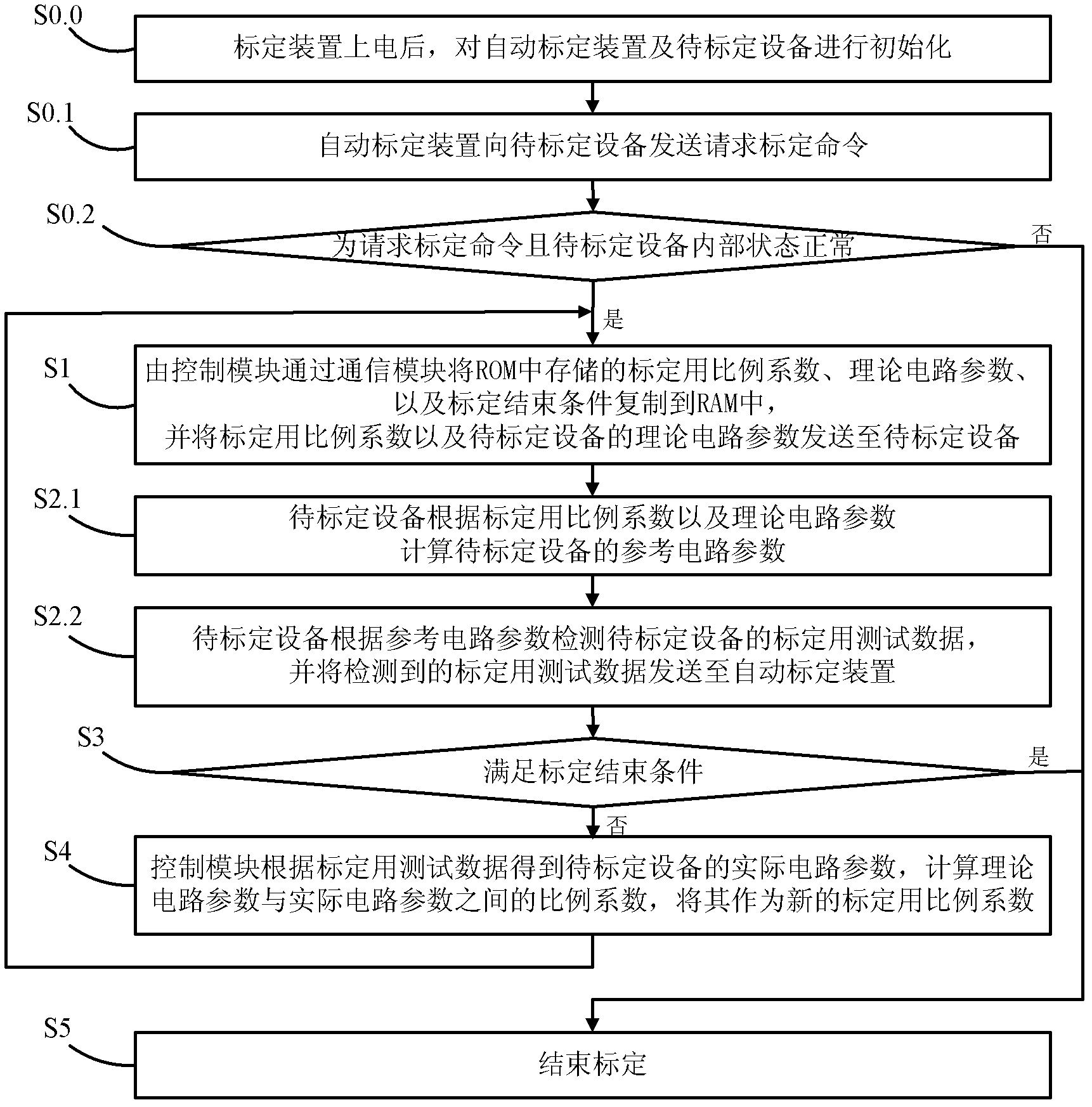

[0022] The automatic calibration device and method based on the CCP protocol proposed by the present invention are described in detail as follows in conjunction with the accompanying drawings and embodiments.

[0023] The device and method of the present invention are all based on the CCP protocol. The CCP protocol is a CAN bus-based ECU calibration protocol. The CCP protocol can be used to quickly and effectively realize the calibration of the automobile ECU. The CCP protocol is the application layer protocol of CAN communication. It is mainly used to realize the calibration of the ECU. At the same time, it can perform cycle or event-driven data collection and detection, and can randomly read the RAM and ROM data in the ECU, and has software and data security. protection function. The CCP protocol is a protocol based on the master-slave communication mode. There is only one master ECU in the system, which can connect to one or more slave ECUs. All commands are issued by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com