Paper cup heat resisting sheet structure

A technology of heat insulation sheets and paper cups, which can be applied to drinking utensils and other directions, can solve the problems of increasing the space and cost of packaging and transportation, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

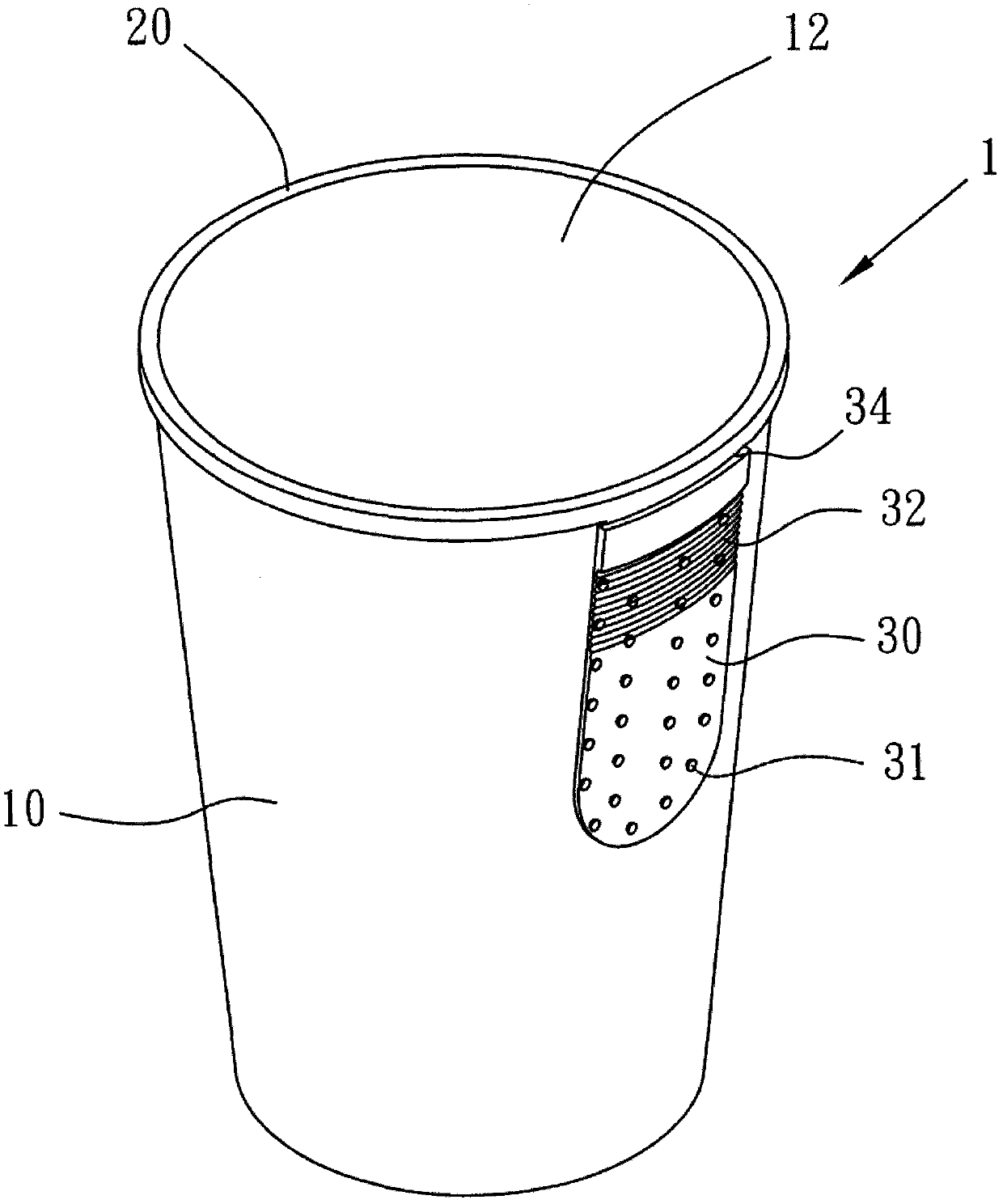

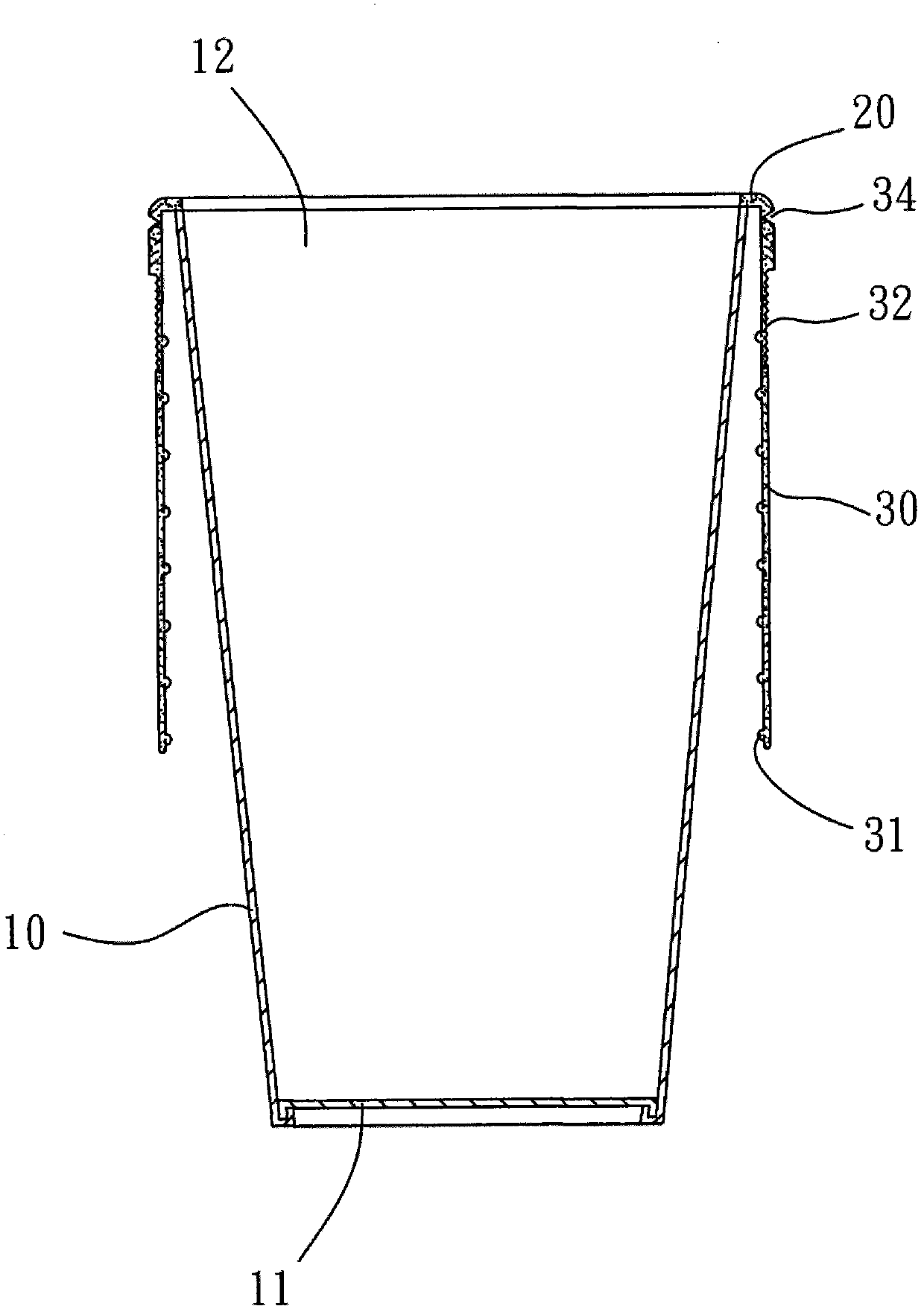

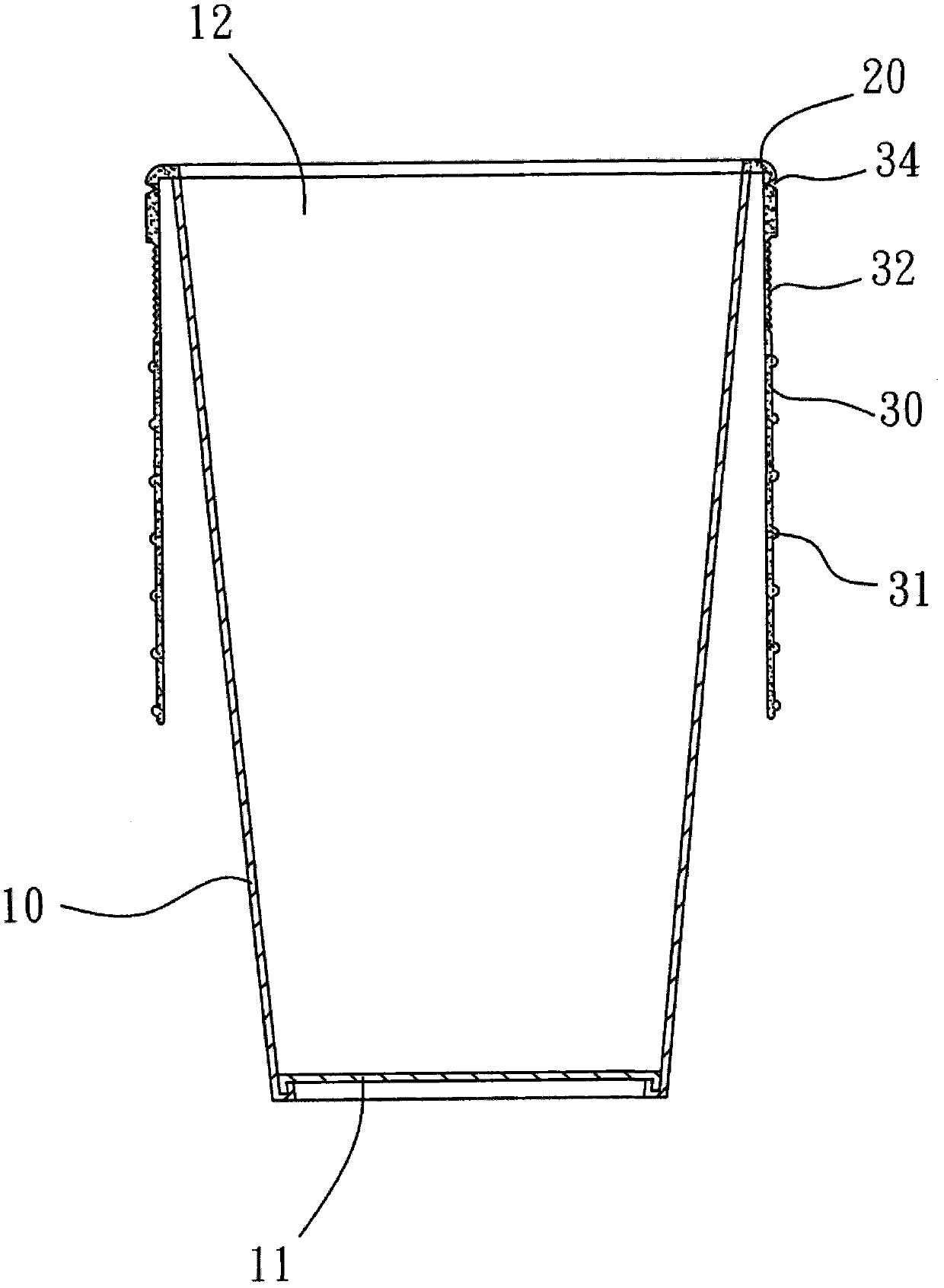

[0022] see Figures 1 to 8 As shown, the "paper cup heat insulation sheet structure" of the present invention includes a paper cup (1), and the paper cup (1) is a cup body (10), a cup edge (20) made of a paper material, and several heat insulation sheets ( 30) and other components, wherein:

[0023] The cup body (10) is a general paper cup structure, which is formed by winding paper boards. The bottom edge is fixed with a cup bottom (11), and the upper shape forms an open cup mouth (12), and the cup mouth (12) The outer edge is provided for this cup edge (20) to combine.

[0024] The cup rim (20) is circular in shape corresponding to the cup mouth (12), and is made of general plastic material, biodegradable plastic material or bioplastic, and can be molded by in-mold injection molding. It is integrally molded on the outer edge of the cup mouth (12) of the cup body (10), or formed by external means such as heat pressing and high frequency wave. Mainly when the cup rim (20) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com