Electric-control stroke-adjustable vehicle-mounted water pump flange pressing machine

A pressing machine and stroke technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long time for production change adjustment, high production cost, difficulty in meeting high-precision product requirements, etc., and achieve convenient and fast production change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

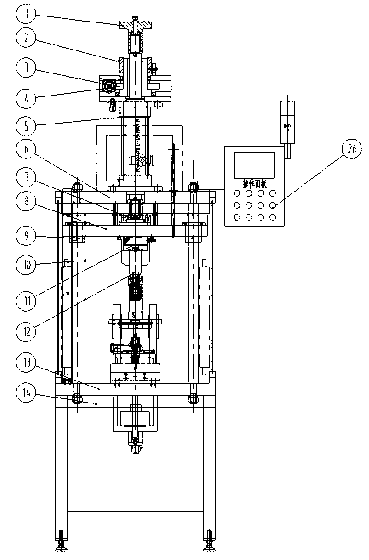

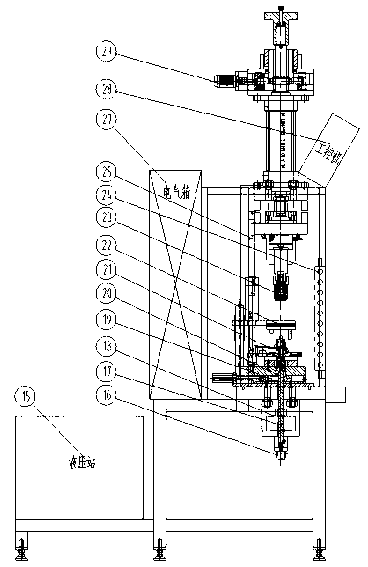

[0012] The electronically controlled and adjustable stroke vehicle-mounted water pump flange pressing machine adopted by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Please refer to figure 1 , figure 2 , the electronically controlled adjustable stroke vehicle-mounted water pump flange pressing machine described in this embodiment includes a frame 14; a hydraulic station 15; an electrical control box 27 is located on the frame 14; an operation panel 26 is connected to the electrical control Box 27, for inputting control commands; base plate 13, disposed on the frame 14; guide column 10, disposed on the base plate 13, connecting the top plate 6 and the base plate 13, and perpendicular to the base plate 13; The clamping chuck 18 is arranged on the frame 14; the upper wedge 20 and the lower wedge 19 are arranged on the bottom plate 13 to clamp the workpiece, namely the water pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com