A method for treating disperse dye wastewater with high chloride salt content

A technology of disperse dyes and treatment methods, which is applied in the field of treatment of disperse dye wastewater with high chloride salt content, can solve the problems of high wastewater load, difficulty in maintaining stable microbial activity, and high concentration of chlorine-containing salts, so as to reduce engineering investment and operating costs, Effect of increasing sludge concentration and biological activity, flexible operation space and variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A disperse dye wastewater with high chloride salt content, the chlorine salt content in the wastewater is 10040mg / L, COD=1310mg / L, B / C=0.11.

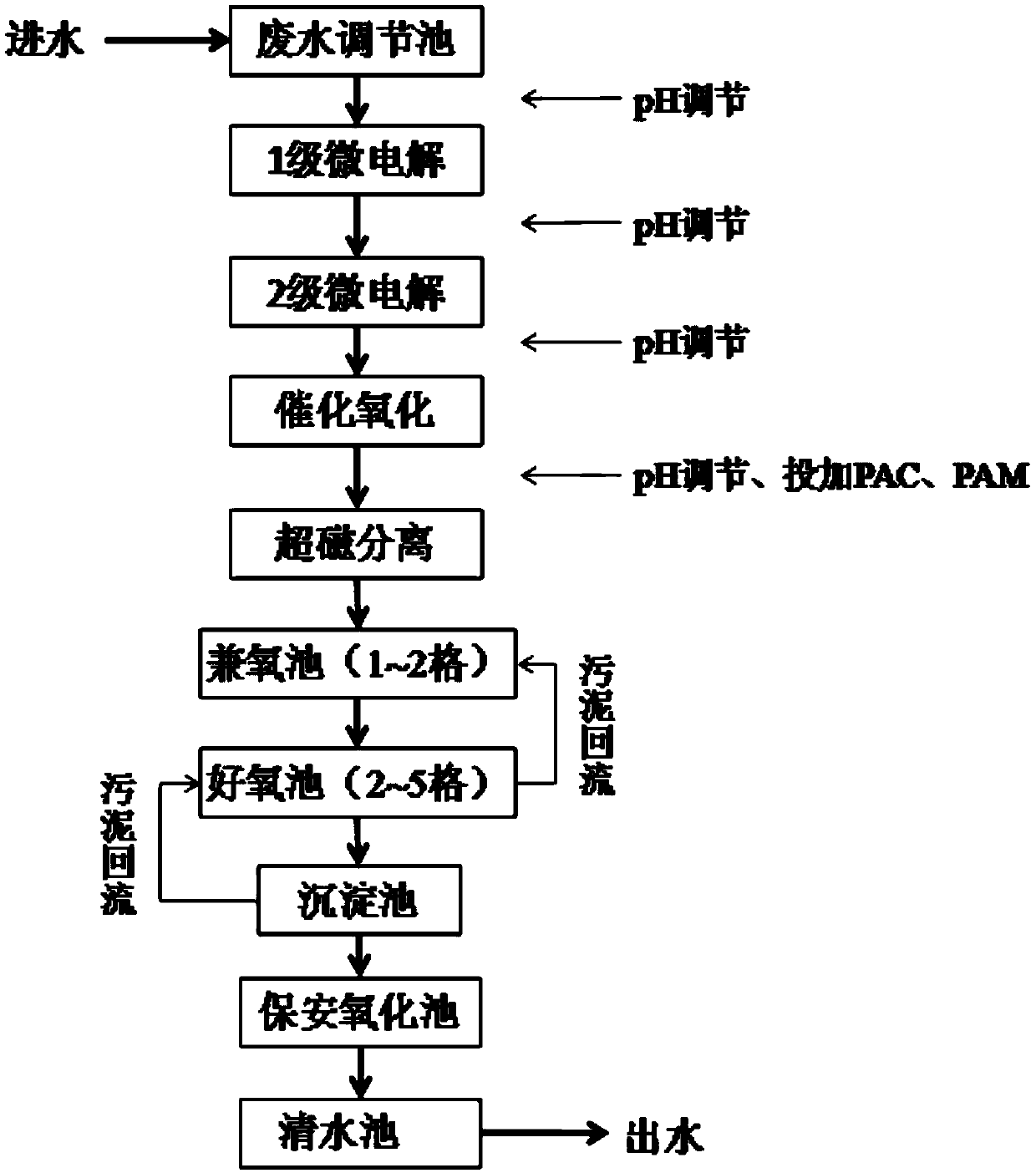

[0038] like figure 1 Shown, this wastewater treatment method comprises the following steps:

[0039]1) Treat the disperse dye wastewater with high chloride salt content in the wastewater regulating pool through a multi-component catalytic oxidation pretreatment check system, which includes a first-level micro-electrolysis system and a second-level micro-electrolysis system connected in sequence and a catalytic oxidation system; the catalytic oxidation system is filled with an oxidation reaction catalyst.

[0040] Wherein, micro-electrolysis reactor is arranged in described 1st stage micro-electrolysis system and 2-stage micro-electrolysis system, and the filler of described micro-electrolysis reactor is multi-element micro-electrolysis filler, and described multi-element micro-electrolysis filler is made of activated carbon, act...

Embodiment 2

[0051] A disperse dye wastewater with high chloride salt content, the chlorine salt content in the wastewater is 15100mg / L, COD=2040mg / L, B / C=0.13.

[0052] The wastewater treatment method comprises the following steps:

[0053] 1) Treat the disperse dye wastewater with high chloride salt content in the wastewater regulating pool through a multi-component catalytic oxidation pretreatment check system, which includes a first-level micro-electrolysis system and a second-level micro-electrolysis system connected in sequence and a catalytic oxidation system; the catalytic oxidation system is filled with an oxidation reaction catalyst.

[0054] Wherein, micro-electrolysis reactor is arranged in described 1st stage micro-electrolysis system and 2-stage micro-electrolysis system, and the filler of described micro-electrolysis reactor is multi-element micro-electrolysis filler, and described multi-element micro-electrolysis filler is made of activated carbon, activated iron powder, A...

Embodiment 3

[0065] A disperse dye wastewater with high chloride salt content, the chlorine salt content in the wastewater is 21900mg / L, COD=3360mg / L, B / C=0.12.

[0066] The wastewater treatment method comprises the following steps:

[0067] 1) Treat the disperse dye wastewater with high chloride salt content in the wastewater regulating pool through a multi-component catalytic oxidation pretreatment check system, which includes a first-level micro-electrolysis system and a second-level micro-electrolysis system connected in sequence and a catalytic oxidation system; the catalytic oxidation system is filled with an oxidation reaction catalyst.

[0068] Wherein, micro-electrolysis reactor is arranged in described 1st stage micro-electrolysis system and 2-stage micro-electrolysis system, and the filler of described micro-electrolysis reactor is multi-element micro-electrolysis filler, and described multi-element micro-electrolysis filler is made of activated carbon, activated iron powder, T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com