Pneumatic tyre for all-terrain vehicle

An all-terrain vehicle and pneumatic tire technology, which is applied in tire parts, tire tread/tread pattern, vehicle components, etc. The effect of strong, improving traction and deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

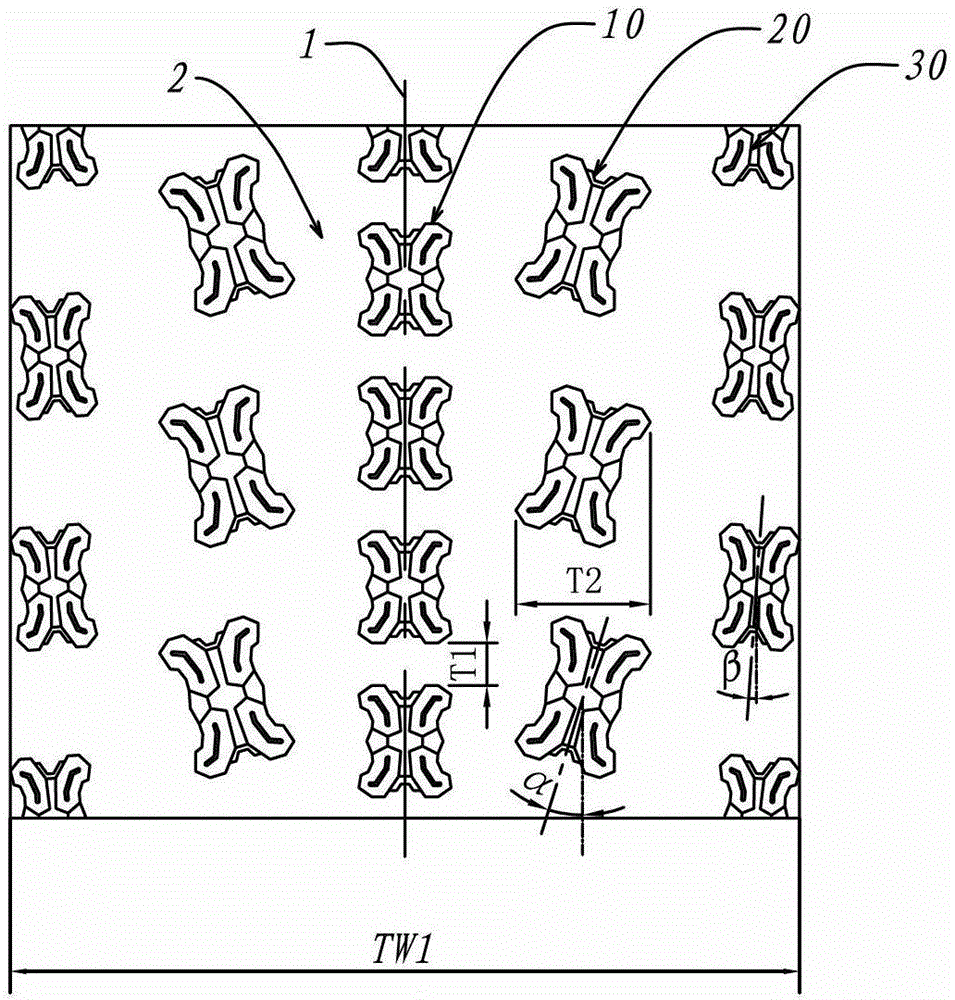

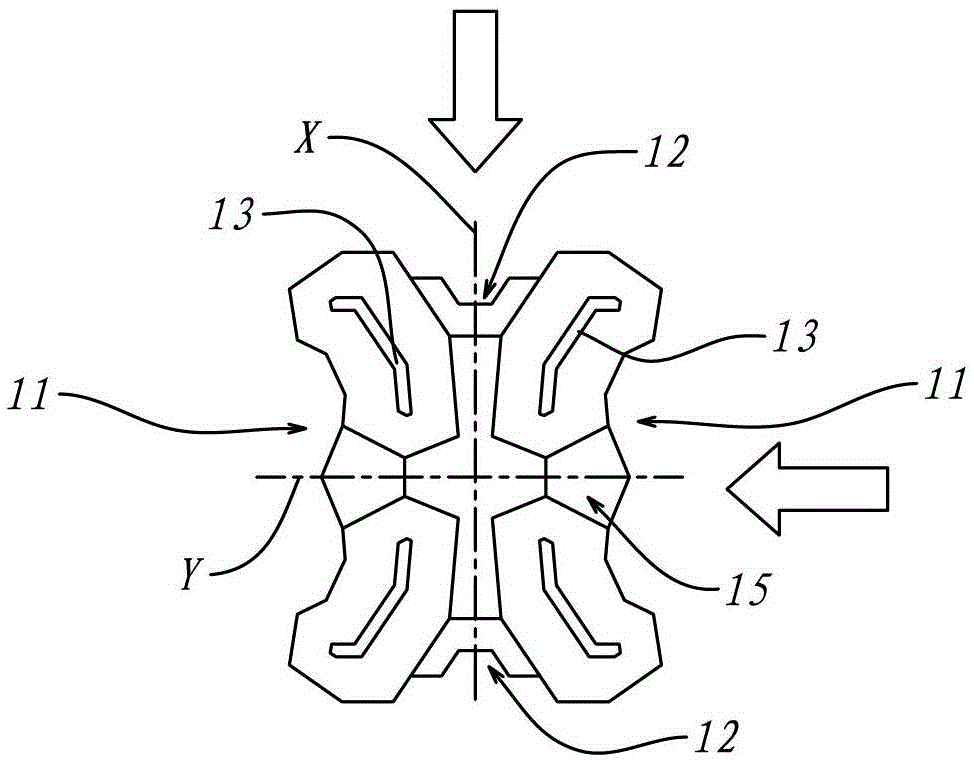

[0026] figure 1 It is a schematic plan view of the tire body of the pneumatic tire for all-terrain vehicles in this embodiment when the tread 2 is unfolded on a plane. , which are the central pattern block 10, the shoulder pattern block 20 and the side pattern block 30. All the pattern blocks are in the shape of protruding blocks on the tread 2, such as image 3 As shown, each pattern block in this embodiment has a long axis X and a short axis Y; the long axis X corresponds to the direction of the vertical grooves 12 oppositely arranged on the pattern block, and the long axis X is located The size of the pattern block is larger than that of the pattern block in the direction of the minor axis Y; the minor axis Y corresponds to the direction in which the relatively vertical groove 11 is located; the setting of the major axis X and the minor axis Y is that each pattern block is allowable image 3 The two directions indicated by the hollow arrows clearly grip the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com