Non-electric continuous type hardware fitting energy consumption testing method

A test method, non-electrical technology, applied in the direction of electric power measurement through current/voltage, etc., can solve problems such as insufficient understanding of sustainability effects, complex analysis and calculation, and no finalized measurement devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

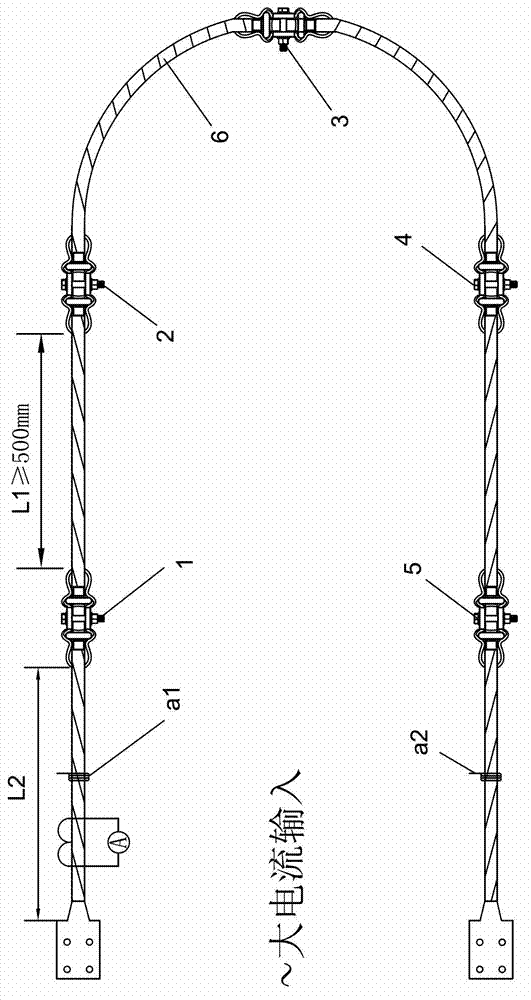

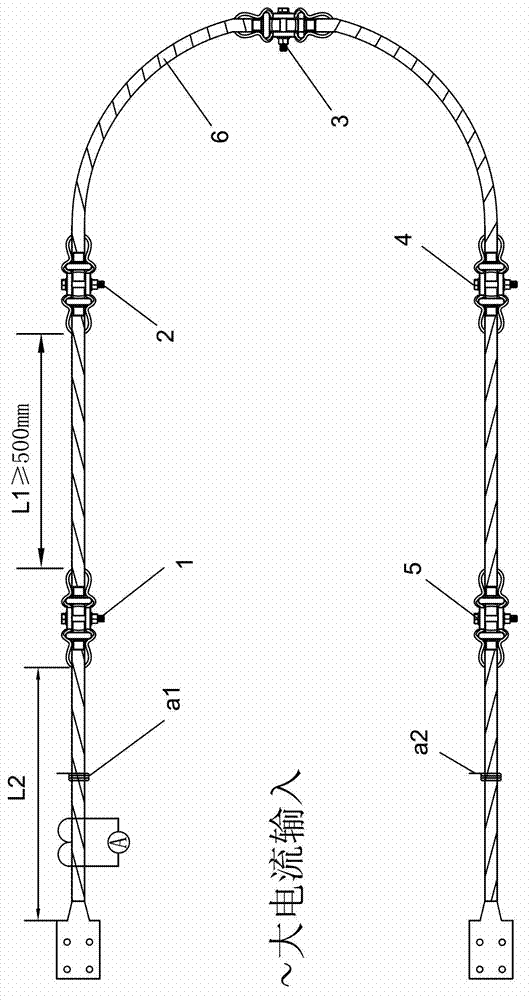

[0037] refer to figure 1 and figure 2 , the energy consumption test method of the non-electrical connection type fittings of the present invention, take the suspension clamp as an example, carry out according to the following steps:

[0038] 1) Select a test lead as follows:

[0039] a) For fittings used for connection of wires of a single specification, the conductor cross-section of the test wire is consistent with the wire cross-section specified by the tested fittings;

[0040] b) For power fittings used to connect two or more wire cross-sections, the conductor cross-section of the test wire is consistent with the maximum wire cross-section allowed by the tested fittings, and the test is carried out at the corresponding position;

[0041] The test wires are copper wires;

[0042] 2) Fasten the temperature measuring probe to the test wire and cover it with PTFE self-adhesive tape so that it is in close contact with the test wire;

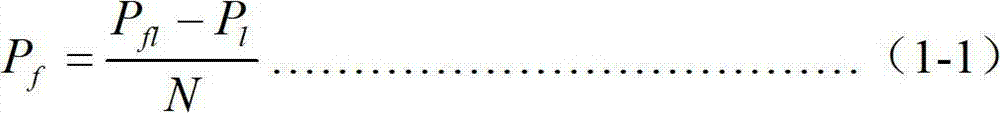

[0043] 3) At the potential test point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com