A gearbox test hydraulic workstation

A technology for hydraulic workstation and gearbox testing, applied in machine gear/transmission mechanism testing, fluid pressure actuating devices, fluid pressure actuating system components, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

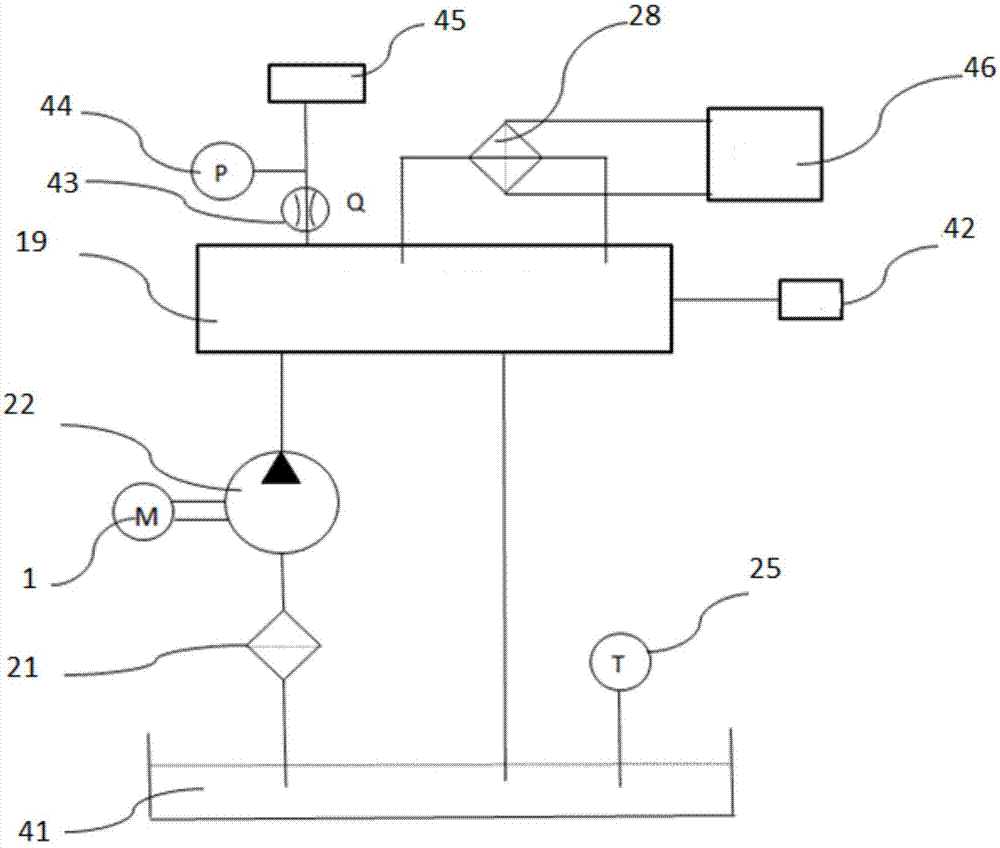

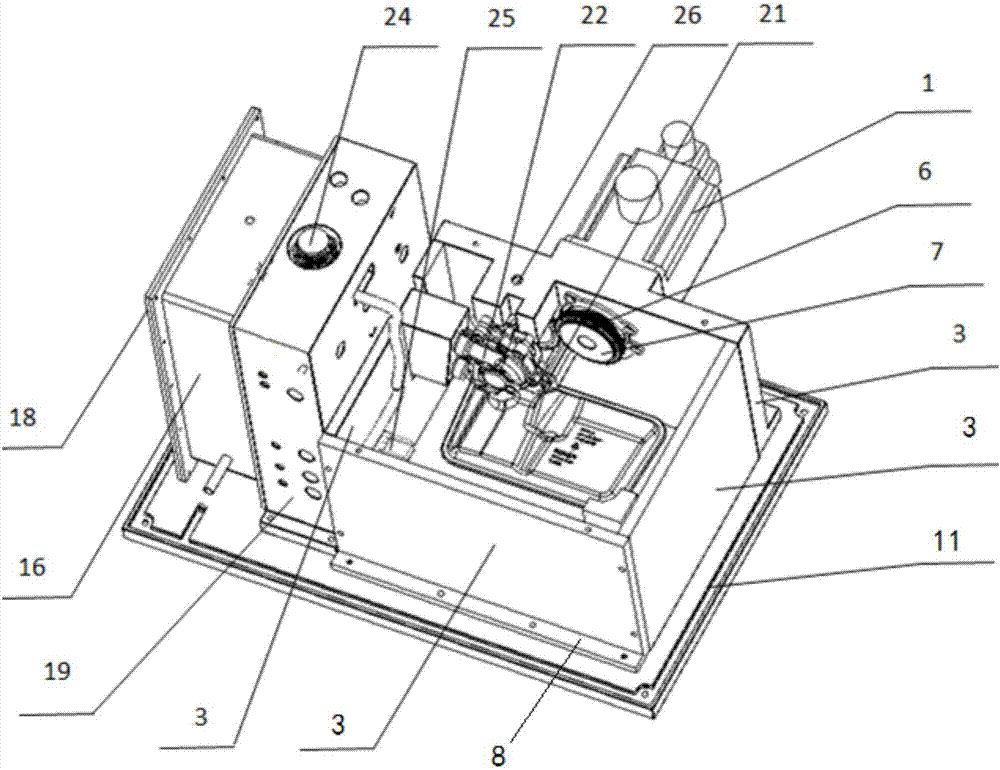

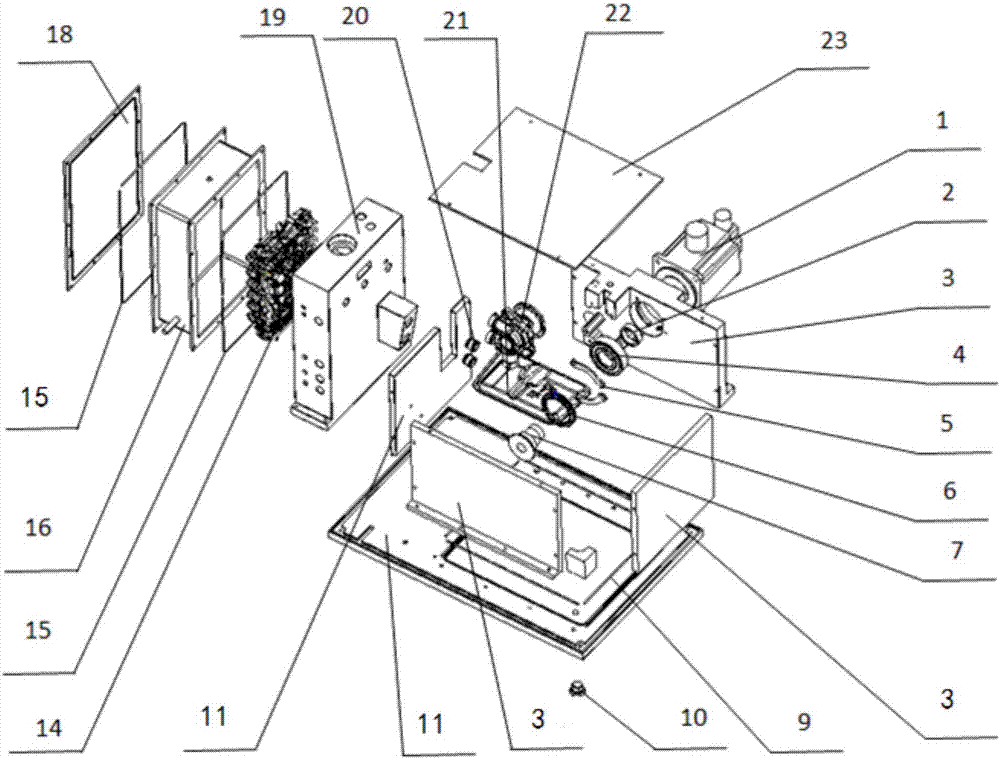

[0018] Such as Figure 1 to 8 As shown, the present invention provides a gearbox testing hydraulic workstation, which includes an oil supply system, a cooling system, and a hydraulic module. The oil supply system includes an oil tank 41 and a gearbox oil pump 22. The gearbox oil pump 22 and the drive The motor 1 is drivingly connected, and the transmission oil pump 22 is connected to the oil pipe input end of the hydraulic module 19, and the oil pipe output end of the hydraulic module 19 is connected to the oil tank 41; the cooling system includes: The cooler 28 is connected to the input and output ends of the cooling pipeline of the hydraulic module 19; the control end of the hydraulic module 19 is connected with a control module 42 (TCU), and the output of the hydraulic module 19 A flow meter 43 and a pressure sensor 44 are connected to the end 45.

[0019] The invention combines the oil supply and cooling methods of the oil in the actual working process of the dual-clutch gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com