Assembly pallet for secondary battery and method for producing secondary battery

A secondary battery and tray assembly technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of no research on the generalization of trays, low utilization of secondary batteries, etc., and achieve the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] First, a first embodiment of the present invention will be described.

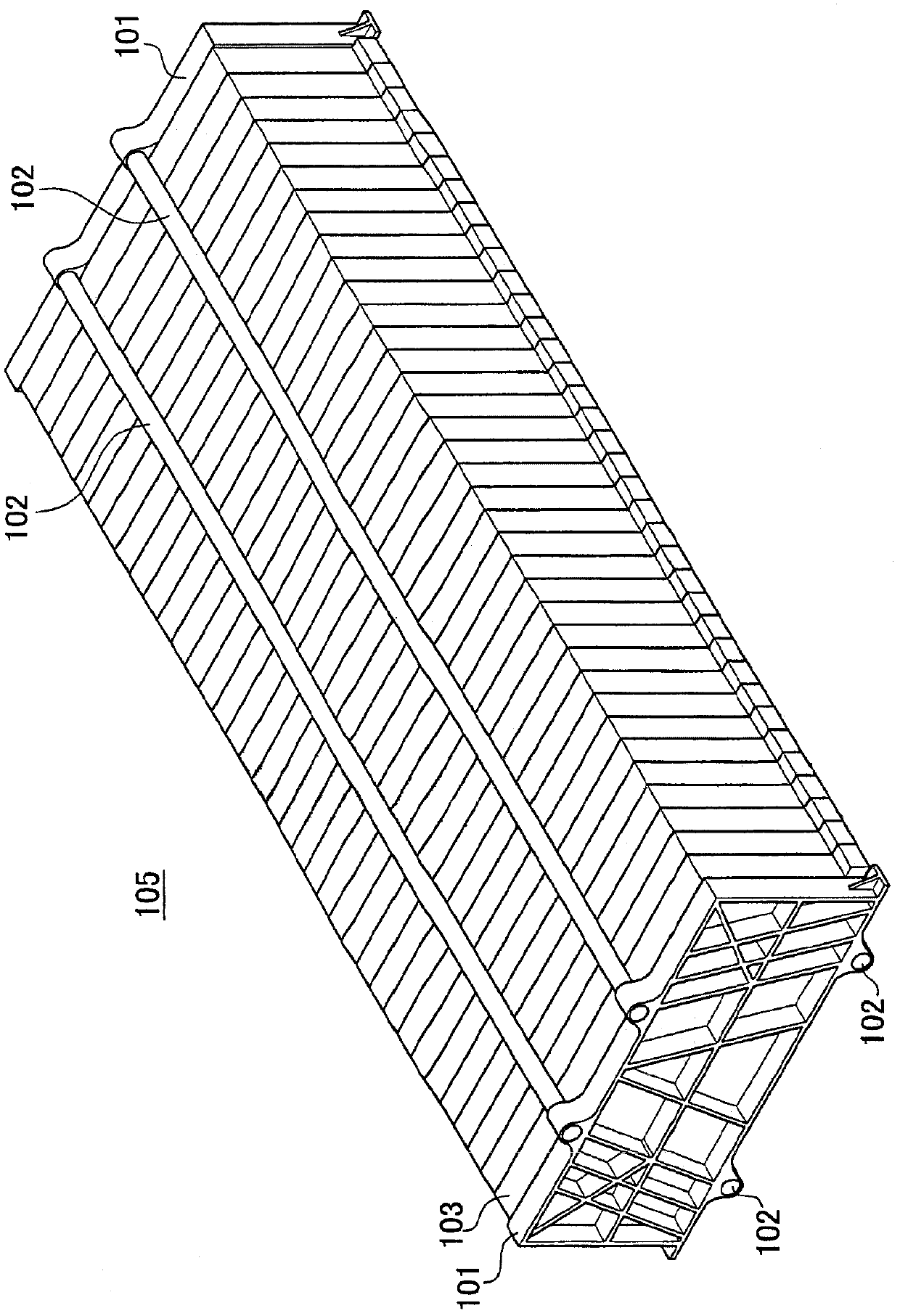

[0043] figure 1 A perspective view showing a stack assembly 105 of the battery cell 100 used in the first embodiment. The stack assembly 105 used in the battery unit 100 is formed by constraining a plurality of stacked cells 103 with two end plates 101 and four constraining parts 102 . The weight of each single cell 103 is about 1 kg, and the stack assembly 105 uses a dozen to several tens of single cells 103 , so the battery unit 100 weighs several tens of kg. The stacked assembly 105 is formed by pressing both sides of the stacked cells 103 with the end plates 101 and combining the four constraining parts 102 .

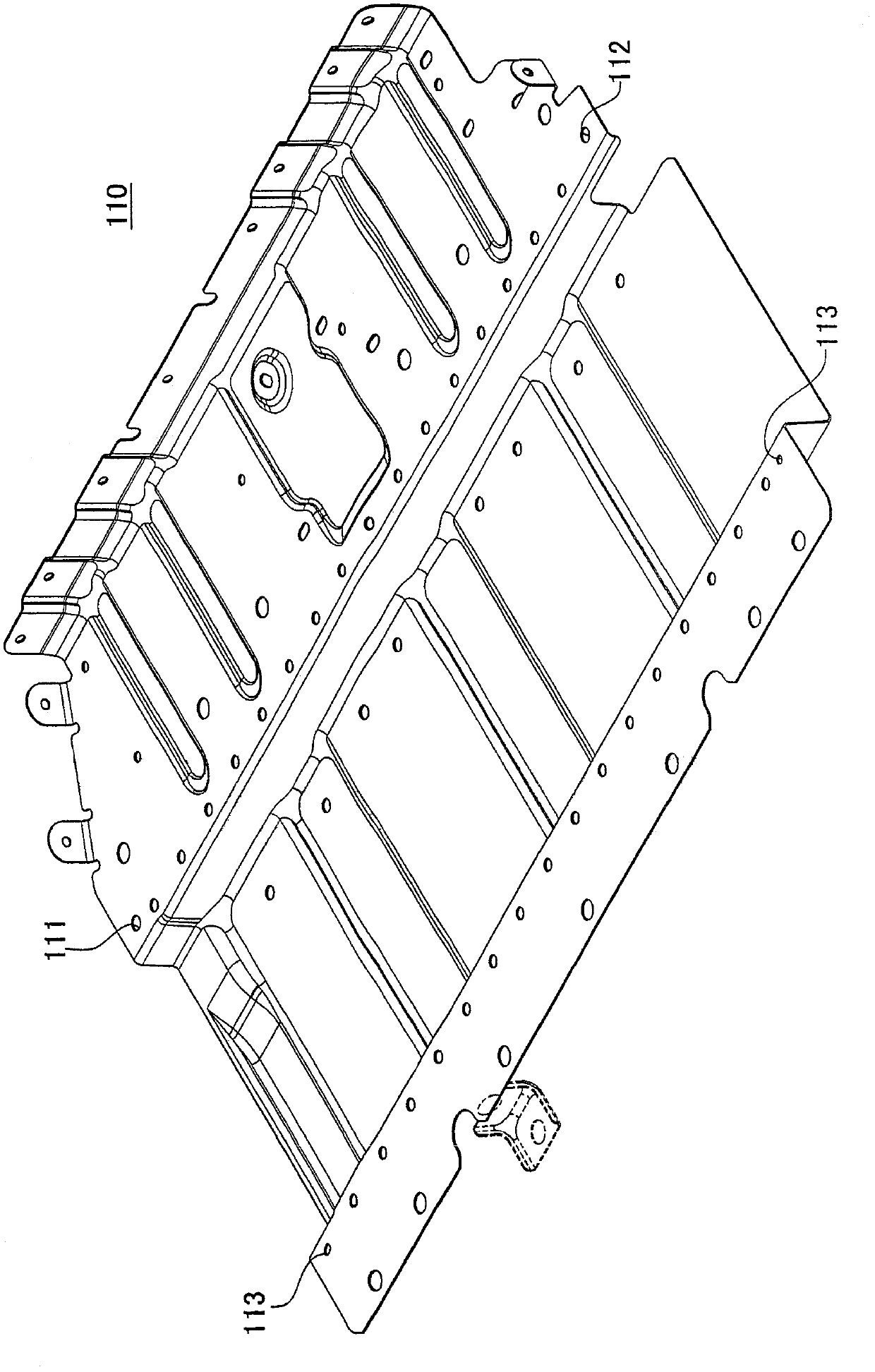

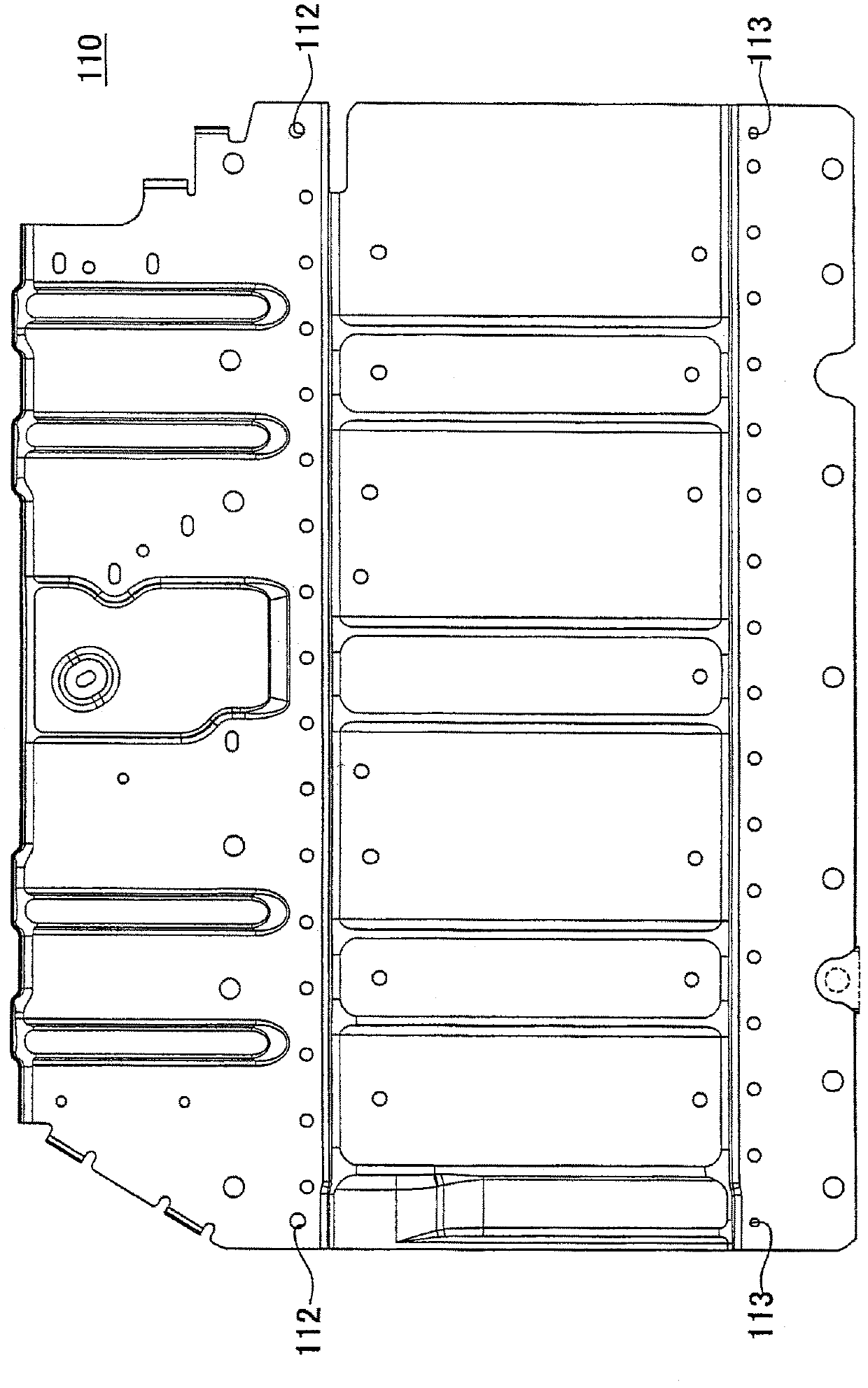

[0044] figure 2 A perspective view of the bottom case 110 for the workpiece A is shown. image 3 A plan view of the bottom case 110 for the workpiece A is shown. Figure 4A side view of the bottom case 110 for the workpiece A is shown. The bottom case 110 for the workpiece A is for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com