Automatic cleaning gradient purifier

An automatic cleaning and purifier technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of inconspicuous purification effect, unsatisfactory cleaning ability, weakened purification rate, etc., and achieve good polarization effect, The effect of improving the automatic cleaning function, improving the purification rate and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

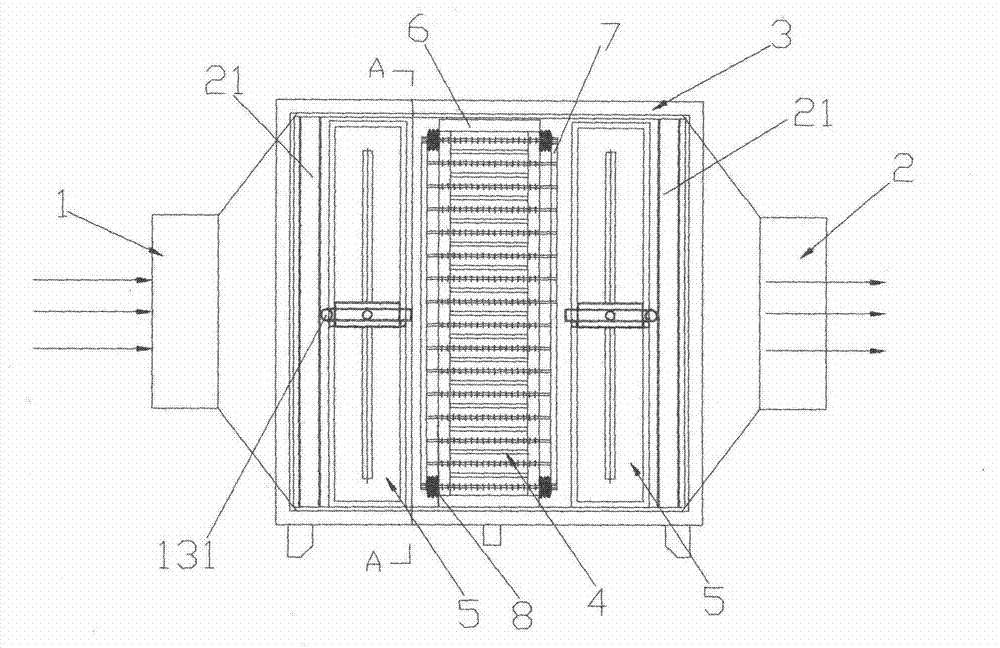

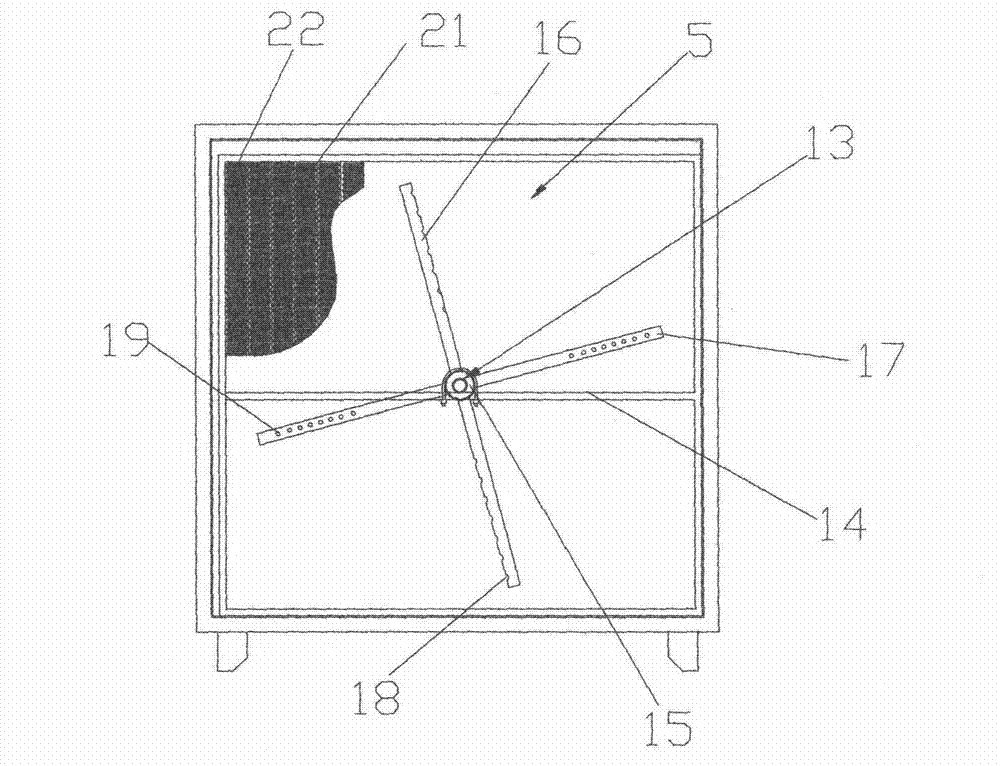

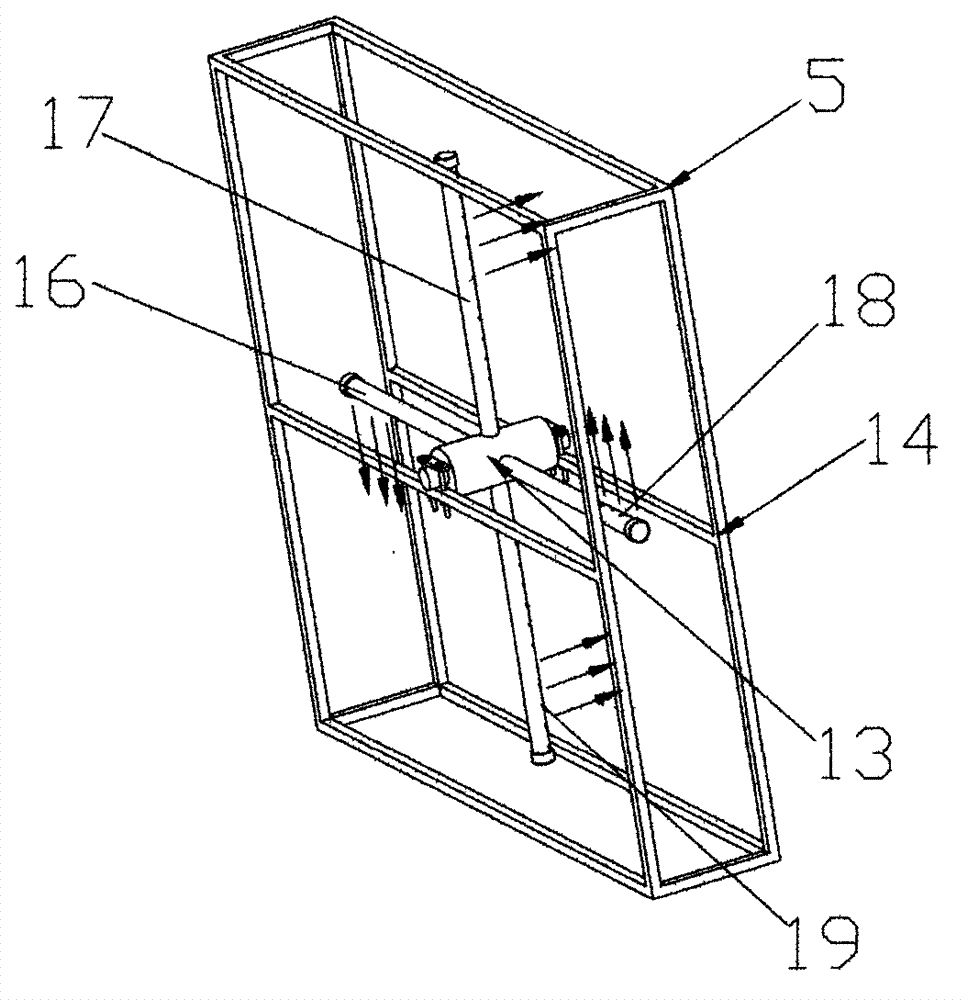

[0029] Such as Figure 1 to Figure 7 The shown self-cleaning gradient purifier includes a square casing 3 with an air inlet 1 and an air outlet 2 and a purifier 4 inside the casing. The purifier 4 is installed in the middle of the casing 3, and a spray device 5 is respectively arranged on both sides of the purifier 4. Specifically, the spray device 5 is arranged at the air inlet and the air outlet of the purifier 4 . The purifier 4 and the shower device 5 are in a horizontal structure.

[0030] The purifier 4 includes an anode metal frame 6 connected to the ground wire and a cathode frame 7 connected to the negative high voltage output terminal, an insulating member 8 is arranged between the anode metal frame 6 and the cathode frame 7, and the anode metal Frame 6 is a frame composed of several small squares 9, the small squares 9 are square squares, and the cathode frame 7 includes a fixed frame 10 and a cathode rod 11, and the fixed frame 10 is for anode metal The conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com